moto Gp, torque pulsing and traction

#51

Posted 12 April 2012 - 00:09

Is 'tire shake' of dragsters analogous to 'wheel hop' in circuit racecars? A longitudinal tire mode (probably stick-slip) and vertical coupling between the tire and chassis causing self-excitation and can render a car uncontrollable. It sounds like 'tire shake' may be the same phenomenon with significantly higher forces?

Advertisement

#52

Posted 12 April 2012 - 03:18

I can't be the only one who suspects that the whole issue is ultimately baloney....I wouldn't be surprised if we don't eventually learn the whole thing comes down to individual rider comfort, feedback, and confidence and there are no tangible benefits that can be materially validated. That is, it's completely subjective.

Of course it can be materially validated, that is the point, it is racing and there is a winner ever time they go out. That basic engine architecture may have to accomodate subjective characteristics is not BS, or any less technically rigorous than chassis architecture and tuning which everyone assumes must accomodate rider/driver preference.

Assuming it is not merely rider preference, the analogy to a TF car is interesting in that the question is of traction not on the macro level where torque/power curves are relevant, but on a micro level, where the graph of crank/drivetrain torsional characteristics would apply. Would a load cell on the hub show the acceleration/deceleration of the drive wheels the same as the crank (with the tire providing torsional damping of each pulse)? Would different firing orders on a TF car make the clutch setup less sensitive, harder to get wrong because there is some traction to be had that way? Or perhaps it could make clutch setup easier but then it could potentially make tire shake worse? Maybe the attempt to experiment with traction affects due to firing order in a car would make more sense in a 410" dirt car. Probably it's already been done, most things have already. But then I'd be curious to know the results.

#53

Posted 12 April 2012 - 10:02

Of course it can be materially validated, that is the point, it is racing and there is a winner ever time they go out. That basic engine architecture may have to accomodate subjective characteristics is not BS, or any less technically rigorous than chassis architecture and tuning which everyone assumes must accomodate rider/driver preference.

Winning doesn't validate any design or feature. Maybe the car/bike won in spite of the new wrinkle rather than because of it, as is so often the case. Or maybe the rider/driver was superior. Or maybe all the other fast guys broke, crashed, or committed errors in strategy. Maybe.... sigh. You get the point.

We have a proposition on the table: that an uneven firing order increases longitudinal grip via some property or mechanism in the tire or tire/surface interface. Ok then, how? If a rider prefers uneven firing order for his own reasons, that is a perfectly valid reason for employing it. However, that's a totally different proposition that does not speak to the question at hand.

#54

Posted 12 April 2012 - 11:24

As long as the clutch is slipping the final drive of a TF does not see any torque oscillation resulting from cylinder firing.Would a load cell on the hub show the acceleration/deceleration of the drive wheels the same as the crank (with the tire providing torsional damping of each pulse)? Would different firing orders on a TF car make the clutch setup less sensitive, harder to get wrong because there is some traction to be had that way? Or perhaps it could make clutch setup easier but then it could potentially make tire shake worse? Maybe the attempt to experiment with traction affects due to firing order in a car would make more sense in a 410" dirt car. Probably it's already been done, most things have already. But then I'd be curious to know the results.

#55

Posted 12 April 2012 - 14:37

Hmmmm. I would be intuitively very surprised if a slipping clutch coupling not only attenuated the highs of the oscillation but filled in the lows to create a constant output torque. Doesn't seem possible. It would certainly lessen the amplitude though. Wouldn't one need a flywheel of essentially infinite mass (how to get that baby turning!?!) to completely decouple input torque variations from output?As long as the clutch is slipping the final drive of a TF does not see any torque oscillation resulting from cylinder firing.

#56

Posted 12 April 2012 - 17:09

Hmmmm. I would be intuitively very surprised if a slipping clutch coupling not only attenuated the highs of the oscillation but filled in the lows to create a constant output torque. Doesn't seem possible. It would certainly lessen the amplitude though. Wouldn't one need a flywheel of essentially infinite mass (how to get that baby turning!?!) to completely decouple input torque variations from output?

You are suggesting that the friction coefficient is velocity-dependent (for non-zero velocities, of course, since we are specifying that the clutch *is* slipping). In fact you even seem to be suggesting that higher friction would occur with higher velocities, which would be rather unusual for what I think of as normal clutch materials.

#57

Posted 12 April 2012 - 21:45

Winning doesn't validate any design or feature. Maybe the car/bike won in spite of the new wrinkle rather than because of it, as is so often the case. Or maybe the rider/driver was superior. Or maybe all the other fast guys broke, crashed, or committed errors in strategy. Maybe.... sigh. You get the point.

We have a proposition on the table: that an uneven firing order increases longitudinal grip via some property or mechanism in the tire or tire/surface interface. Ok then, how? If a rider prefers uneven firing order for his own reasons, that is a perfectly valid reason for employing it. However, that's a totally different proposition that does not speak to the question at hand.

Well, yes, the ‘if he wants gold handelbars…’ effect is certainly real, doesn’t mean gold handlebars make everyone faster. Leg dangling on corner entry could be hand waivingly explained by physics, but surely it is a case of monkey see monkey do (albeit very fast monkeys). But at that level, changing V angles and firing order with subsequent packaging headaches, etc are ‘gold handelbars’ on another scale entirely, one would think the factories could come up with some more cost effective placebo like gold footpegs? I know, correlation not necessarily causation, but still, if that’s the case a MotoGP engine has to be one of the most expensive placebos on earth.

So, putting that to the side, firing order vs. traction. Static is always higher than dynamic friction, so the theory is that interrupting/discretizing the application of torque during a slide improves the average friction at the tire (to something between the static and dynamic coefficients). Same as pedaling a car in a straight line when it spins up, it’s faster to let off, so the tire slows back down to ground speed, before applying throttle again. Pedaling the gas is obviously a very gross phenomon, but is it so different from the idea that firing order might have a similar effect on a smaller scale? This is the common ‘tire relaxation’ argument for big bang firing orders and intuitively I could talk myself into it. Sliding is necessary to turn the bike and finish the corner, so maximizing traction in that critical time just as the throttle is opened up is key to winning. Actually the season opener at Qatar last week showed Stoner’s patented ‘mini highside’ method of standing the bike up and getting on the gas when he drove past Lorenzo coming onto the straight, which certainly negates to some degree the effectiveness of firing order changes (assuming there is a benefit). But there are not so many Stoner’s on the grid….

Further, from a feedback perspective, I could believe that interrupting/discretizing the application of torque allows that much more time increment for the control system (human or electronic) to respond to significant traction loss. Or conversely that it would become easier to just “ride it out”, and keep the throttle pinned or just about, because of the predictability of the (continuously interrupted) slide. Given the necessity for electronic intervention, I could see that this would be a benefit. Especially in the early years of the 990’s the throttles were operated both by cable and by ECU and it was early in the development of all of those electronic aids.

GG - On the clutch slippage thing, it is engine torque causing the slip, if there are torque oscillations at the crank, I don’t see how the clutch could continue to slip at a constant rate, that would mean the clutch applies back driving torque to the crank which doesn’t seem realistic in the midst of very hard acceleration. If it was a one cylinder 4 stroke the clutch would slip once per cycle (for ~180 deg), applying high torque to the wheels, and for the rest of the cycle (540 deg) there would be no slip, torque applied would be due to engine inertia only, certainly much less than the torque from the power stroke. Load cell on the drive wheels should show periodic torque fluctiation directly related to cylinder firing.

#58

Posted 12 April 2012 - 22:55

As far as I understand the clutch slip has all stopped by about a third of the distance.As long as the clutch is slipping the final drive of a TF does not see any torque oscillation resulting from cylinder firing.

Occasionally you see them light the tyres up over the line.

#59

Posted 13 April 2012 - 00:09

For TF the clutch slip is constant not intermittent and the torque immediately either side of the clutch will be constant. As you move away from the clutch, inertia combined with velocity oscillations will create torque oscillations but these are purely inertial and isolated from the other side of the clutch ie engine firing oscillations only on the engine side and tyre stick-slip oscillations on the wheel side of the clutch.GG - On the clutch slippage thing, it is engine torque causing the slip, if there are torque oscillations at the crank, I don’t see how the clutch could continue to slip at a constant rate, that would mean the clutch applies back driving torque to the crank which doesn’t seem realistic in the midst of very hard acceleration. If it was a one cylinder 4 stroke the clutch would slip once per cycle (for ~180 deg), applying high torque to the wheels, and for the rest of the cycle (540 deg) there would be no slip, torque applied would be due to engine inertia only, certainly much less than the torque from the power stroke. Load cell on the drive wheels should show periodic torque fluctiation directly related to cylinder firing.

Advertisement

#60

Posted 13 April 2012 - 00:29

CLUTCH, FLYWHEEL, FLYWHEEL SHIELD

Flywheel and clutch meeting SFI Spec 1.3 and flywheel shield

meeting SFI Spec 6.2 mandatory. Maximum depth of flywheel

shield: 9.4 inches (inside). Maximum six clutch discs permitted. The

use of aluminum flywheels is prohibited. Clutch exhaust filter

mandatory. Refer to General Regulations 2:3, 2:5, 2:6, 2:7, and SFI

Spec 2.3N for complete motor plate and bellhousing guidelines.

DRIVELINE

Anti-blowback device mandatory. See General Regulations 2:1.

REAR END

Rear-end gear ratio restricted to 3.20:1 only; may be no lower or

higher. Aftermarket full-floating or live axle assembly mandatory.

Periodic Magnaflux check of axles recommended. Front-loading or

pumpkin-style rear end prohibited at all national events. See

General Regulations 2:11. All hubs must be drive hub type and

must mate with required drive-hub-type wheel.

TRANSMISSION

Reverser mandatory. Neutral lockout release pin mandatory.

Transmission prohibited. See General Regulations 9:7.

REVERSER SHIELD

A one-piece ballistic shield covering all units mandatory. Must meet

SFI Spec 4.1. See General Regulations 2:13.

#61

Posted 13 April 2012 - 00:56

#62

Posted 13 April 2012 - 12:15

Apparently the big bang engine can deliver a less noisy torque to the wheel which improves rider feel. Why tire life is improved is not clear but maybe the tires is more happy with lower frequency torque input? Or the riders just conserves the tire better with better feel?

-----------------

Why Big Bang Engines Work

By Scott Jones

http://blogger.xs4al.../24/355605.aspx

"...Which brings us to a more current theory, that of Yamaha's chief engineer, Masao Furusawa. At the end of the 2007 season, Furusawa gave a presentation in which he explained his theory of the big banger's benefits in terms of the engine's internal harmonics. Instead of reintroducing gradual lateral slipping to help the rider sense the limit of grip, the quick dual pulses of the big bang engine create a much different harmonic state during acceleration.

Just as the tire in the previous theory can sense subtle differences in the forces of the accelerating and decelerating piston, the crankshaft in Furusawa's theory creates a noticeably different harmonic signature when the pistons are fired in close succession.

Again we are dealing with milliseconds and distinct changes in the movement of various engine parts during those very brief periods. Friction causes the piston to decelerate after combustion, and so does the necessity of reversing direction when the piston approaches top dead center and bottom dead center. Again, think back to beginning physics and how something moving in a given direction at a given velocity wants to keep doing just that. After ignition, the piston is moving very quickly down the bore until it reaches the limit imposed by the connecting rod. Rather suddenly it is forced to stop, and then head in the opposite direction. As it is moving down the bore, it has considerable inertia and kinetic energy, both of which have to be accounted for as part of the reverse of direction. Both forces are absorbed by the crankshaft, something Furusawa called 'inertia torque' to differentiate these forces from combustion torque, the force created by the ignition of the fuel mixture.

Just as wind resistance increases exponentially as speed climbs, so inertial torque increases as the revs climb. So while inertia torque is a factor in your road bike, you don't operate its engine at sufficient revs to notice a problem. But MotoGP engines run fast enough that inertia torque becomes a very noticeable problem indeed.

To explain just how this problem manifests itself on the track, Furusawa used the metaphor of tuning a radio. As you turn the dial searching for the desired station, you hear the noise of signal interference decrease as you approach a spot where the signal strength is at its peak. The noise is still there, but the interference is low enough that you hear a clear signal. In Furusawa's metaphor, the rider is using the throttle to tune in a good signal to the rear tire. If there is too much noise between the throttle and the tire, the rider doesn't sense a strong signal and has little notion of where the limit of traction lies. If the interference is low enough, the rider has a good connection to the tire via the throttle and can get closer to the limit of traction.

Inertia torque is noisy, and thus interferes with the rider's ability to tune in a good signal. Enter the big banger, which reduces the periods of inertia torque by compressing the firing pattern. As the crankshaft is absorbing inertia and kinetic energy from the pistons and connecting rods, it's doing so in a smaller window of its revolution. The result is a longer period of each revolution that is noise free, or relatively so, giving the rider a stronger signal between the throttle and the rear tire."

-----------------

Techspeak - Crossplane Crankshaft

Report by Mihir Gadre

http://motoroids.com...ane-crankshaft/

#63

Posted 13 April 2012 - 18:56

I'll now re-ask one of my first questions - has F1 ever tried this - and answer it by saying that

a) with V- 8 engines there are less permutations which squeeze the torque into only part of each revolution

b) They are not torque limited like Moto GP bikes due to all the huge aero available

c) The F1 tyre construction is different to a bike

So maybe an F1 car simply doesn't have to operate in the bike or Top Fuel window so the idea wasn't worth trying

#64

Posted 13 April 2012 - 20:51

Actually it is tyre wear related, take away firing order and look into engine internal components as you pointed out, (that forces them to an uneven firing order or anything that works) it might not be vibrating from its position, mount or causing engine vibration but by the way it spins that seems to effect tyre wear. Conventional flat plane crank inherits it while cross plane creates a smoother spin pattern, a more consistent internal mass control that ask less of a tyre to dampen it.I don't think it was traction related experiment, and I would venture a guess that they felt that it was worth to have a go on account of (I think it was significantly) reduced inertia of engine internal components.

Watch here

Edited by Powersteer, 13 April 2012 - 20:59.

#65

Posted 14 April 2012 - 00:53

Actually it is tyre wear related, take away firing order and look into engine internal components as you pointed out, (that forces them to an uneven firing order or anything that works) it might not be vibrating from its position, mount or causing engine vibration but by the way it spins that seems to effect tyre wear. Conventional flat plane crank inherits it while cross plane creates a smoother spin pattern, a more consistent internal mass control that ask less of a tyre to dampen it.

Watch here

Yes, in theory it looks rather nice, but in the hindsight ISTR those advantages didn't show on stop-watch and it was abandoned in favour of flat-plane (this RET-Monitor article seems to agree on its lack of competitiveness and impact). I recall doing a relatively crude analysis, at the time I was helping a friend with his final 'thesis' at Uni, using a generic four-stroke p/V diagram with only piston inertia taken into account (admittedly at constant crankshaft speed), and it seems that with flat-plane I4 the oscillations in torque are almost 4x bigger than with cross-plane. I just dug out the file, and here's the torque curve for both (and it is indeed an odd 'hypothetical engine', but I think it shows general trend):

#66

Posted 14 April 2012 - 02:31

Reading Furusawa's piece it is clear that the big bang engine is not about increasing the amplitude of torque oscillation, in fact it is quite the opposite. Although torque delivery from the combustion events is less regular, the much larger inertial oscillations are significantly reduced by eliminating the typical 4cyl engine characteristic of all four pistons stationary simultaneously and 90 deg later all four at near maximum velocity. With the cross plane crank arrangement, two pistons are staionary while at the same instant the other two are near maximum velocity.Two articles (below) that describes Yamaha's chief engineer, Masao Furusawa explanaition to why the big bang engines work

Apparently the big bang engine can deliver a less noisy torque to the wheel which improves rider feel. Why tire life is improved is not clear but maybe the tires is more happy with lower frequency torque input? Or the riders just conserves the tire better with better feel?

Why are the tyres happier? It's not the frequency of torque oscillation - its the lower amplitude.

Not sure why 3 cylinders is not an option. The inertial component of oscillation is very low and the firing is evenly spaced. Perhaps the small loss of top end power is significant. 5 or 6 cylinders could be considered (rules permitting).

If it is all about inertial torque fluctuation, the topic is irrelevant to F1 since V8 engines have very low values.

#67

Posted 14 April 2012 - 14:50

A little like Vtec, which works superbly in a road car but was a disaster in CART when Honda tried it.

THe Yamaha M! uses this techa nd it was transferred to the R1 roadbike and also into WSB, it offered good power, tractability and has won the WSB and BSB titles, aliied to a very expensive electroncis suite admittedly.

But as for big bang in two strokes. Honda did it to manage tyre life in 1990/1. Released it in 92 and utterly dominated. Cagiva, Suzuki, Yamaha all followed with arguably the best version being Cagiva's. Then Doohan went back to the pre big bang engine in 97 coz he was fed up of everyone being able to use his data to beat him (now and then)

It was a mind games move more than anything else, but Honda went with it and found that tyre life for Doohan was improved because more importantly he was able to modulate the throttle more and use HIS SKILL to manage the tyres, not just the big bang tech.

The advantage big bang had also was in braking, with a sort of engine braking effect that a normal engine wouldnt have. Again though Schwantz would outbrake anything pre or post big bang and AP would always tell you the best bit about their brakes was Kevin, and he was one of only a few riders in GP500 who could use 6 pot carbons, very few others could get the pressure.

#68

Posted 14 April 2012 - 23:44

I agree that the torque acting on the rear tire is a result of the net forces produced in the engine. The combustion gas pressure acting on the pistons must overcome the negative work occurring due to engine pumping losses, parasitic losses, and frictions. However, the situation is much more complex and dynamic than the author describes it. The relative cycle pressures and frictions can vary greatly over the course of a single engine cycle, and also over the operating speed/load range of the engine.

A motorcycle rear tire driven by a chain also presents a different situation from that in a typical car drivetrain with shaft drive. A chain can only transmit force in tension, not in compression. There is also usually some amount of slack on the coast side of the chain. So the inertia coupling between the rear end and engine/transmission is not the same in a bike as it is in a car.

Lastly, different types of motorcycle racing engines have different requirements when it comes to polar inertias. While road race bikes can benefit from the quick throttle response of low polar inertia engines, speedway bikes actually use lots of flywheel inertia to help them launch at the start.

Interesting discussion.

slider

#69

Posted 15 April 2012 - 00:17

Fog and mirrors, as I said. This topic is the perfect playground for empty speculation.

#70

Posted 15 April 2012 - 04:11

This ignores one of the key points to come out of all this.The relative cycle pressures and frictions can vary greatly over the course of a single engine cycle, and also over the operating speed/load range of the engine.

For a four cylinder foue stroke engine, the torque fluctuations due to cylinder pressure are far less significant than those due to piston inertia.

#71

Posted 15 April 2012 - 04:42

This ignores one of the key points to come out of all this.

For a four cylinder foue stroke engine, the torque fluctuations due to cylinder pressure are far less significant than those due to piston inertia.

gruntguru,

I would say that the opposite is true. With any recip engine, the peak instantaneous torque will occur close to when a cylinder fires. When you have pairs of cylinders of a four cylinder engine firing simultaneously, there will be a larger (2X) initial combustion pressure impulse followed by a longer period where the crank is turned mostly by inertia. With a flat plane I4 crank, these "big bang" combustion pressure impulses would still be harmonic (evenly spaced). With a cruciform I4 crank, the "big bang" combustion pressure impulses would not be harmonic. The torque fluctuation would be reduced during one 360 deg period of crank rotation, but it would be increased during the subsequent 360 deg period of rotation.

With any 4-stroke recip piston engine, combustion pressures vary with load, while piston inertias vary with engine speed.

#72

Posted 15 April 2012 - 09:16

#73

Posted 15 April 2012 - 12:24

For a four cylinder foue stroke engine, the torque fluctuations due to cylinder pressure are far less significant than those due to piston inertia.

I'm sorry but this is just so wrong. All IC engines show cyclic torque fluctuation on engine dyno due to # of cylinders and firing order. A TF V8 will show them every 90 deg, a single cylinder will show them every 720 deg. Cylinder pressure creates ALL the torque available, and only during the power stroke(s) does a crankshaft accelerate. All other cranktrain rotation is due to inertia only, and this does not produce torque, it consumes it. f do not think you could see cranktrain effect with the same # of cyls and firing order on engine dyno at all.

An engine assembly can be 'motored' or spun without combustion to whatever the max fired rpm of the motor using a relatively very low powered electric motor. The torque required to free rotate an engine, which includes the effects of cranktrain inertia's due to layout and firing order, is almost nothing as compared to the torque the engine generates due to cylinder pressure. To detect crankshaft torsional characteristics requires very specialised instrumentation specifically because those effects are so difficult to measure.

Balance shafts exist (in all the MotoGP motors also), specifically to account for cranktrain inertia to balance shaking/combustion forces, but if it was that much an issue they could be used to completely offset or even over-offset for rotational cranktrain inertia.

#75

Posted 15 April 2012 - 13:30

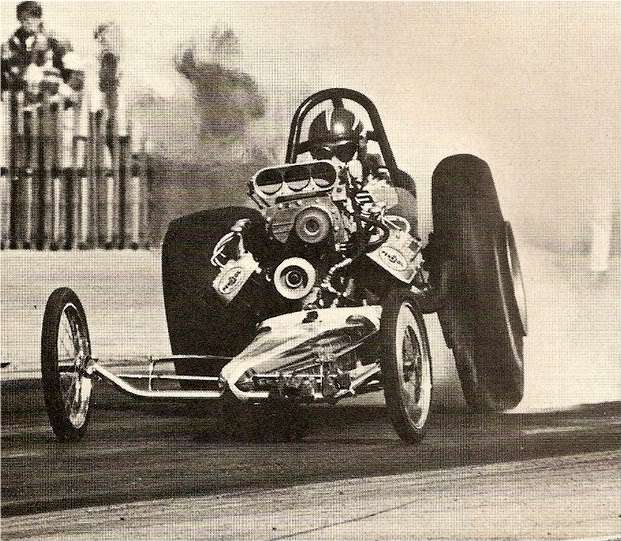

brown trouser moment !

#76

Posted 16 April 2012 - 01:43

1. Broken axle.

2. Open diff (Bad choice) or poor welding of differential gears.

#77

Posted 16 April 2012 - 01:55

4 cyl engines are notorious for inducing torsional vibration - far worse than 3 cyl.I'm sorry but this is just so wrong. All IC engines show cyclic torque fluctuation on engine dyno due to # of cylinders and firing order. A TF V8 will show them every 90 deg, a single cylinder will show them every 720 deg. Cylinder pressure creates ALL the torque available, and only during the power stroke(s) does a crankshaft accelerate. All other cranktrain rotation is due to inertia only, and this does not produce torque, it consumes it. f do not think you could see cranktrain effect with the same # of cyls and firing order on engine dyno at all.

Inertia does not "consume" torque. Averaged over a cycle, the energy attributable to inertia must equal zero. This means that the pistons of a 4cyl accept work from the cranshaft as they accelerate away from BDC and TDC and return that work to the crankshaft as they decelerate towards BDC and TDC.

Balance shafts have no relevence to rotational inertia. They are there to cancel linear inertial effects.Balance shafts exist (in all the MotoGP motors also), specifically to account for cranktrain inertia to balance shaking/combustion forces, but if it was that much an issue they could be used to completely offset or even over-offset for rotational cranktrain inertia.

#78

Posted 16 April 2012 - 13:37

Great pic for sure! Only two possibilities.

1. Broken axle.

2. Open diff (Bad choice) or poor welding of differential gears.

Without researching on the internet - I think a lot of dragsters (and Garlits' first rear-engined car) did actually have "open" diffs.

#79

Posted 16 April 2012 - 14:22

Without researching on the internet - I think a lot of dragsters (and Garlits' first rear-engined car) did actually have "open" diffs.

Considering they did burnouts for most of the runs back in early 60s it would aid in stability.

But it sounds strange tho.

Advertisement

#80

Posted 17 April 2012 - 01:28

Without researching on the internet - I think a lot of dragsters (and Garlits' first rear-engined car) did actually have "open" diffs.

Absolutely right. Spools and locked axles were considered suicide on these cars. They relied on an open differential and an extremely narrow rear track to stay out of the fences.

Not the least of the issues was a total lack of aftermarket parts. With a locked diff, an axle or hub failure would stick the car into the wall quicker than you could blink. No saving it. No chance.

In the photo above, things look rather fraught at first glance but if you examine the situation for a moment, you can see that the setup was remarkably forgiving.

One of Garlits' oft-quoted three "golden rules" for making the original rear-engine cars work right was totally open differential -- no spool, no locker, no limited-slip.

#81

Posted 17 April 2012 - 02:14

I'm sorry but this is just so wrong. All IC engines show cyclic torque fluctuation on engine dyno due to # of cylinders and firing order. A TF V8 will show them every 90 deg, a single cylinder will show them every 720 deg. Cylinder pressure creates ALL the torque available, and only during the power stroke(s) does a crankshaft accelerate. All other cranktrain rotation is due to inertia only, and this does not produce torque, it consumes it. f do not think you could see cranktrain effect with the same # of cyls and firing order on engine dyno at all.

An engine assembly can be 'motored' or spun without combustion to whatever the max fired rpm of the motor using a relatively very low powered electric motor. The torque required to free rotate an engine, which includes the effects of cranktrain inertia's due to layout and firing order, is almost nothing as compared to the torque the engine generates due to cylinder pressure. To detect crankshaft torsional characteristics requires very specialised instrumentation specifically because those effects are so difficult to measure.

GrpB,

During a complete engine cycle (ie. 720 deg in a 4-stroke) the torque produced about the crank axis by the piston is both positive and negative. The positive torque is produced by combustion pressure and also by piston/conrod inertia as the piston/conrod recip mass is decelerated ahead of TDC/BDC. The negative torques are due to frictions, pumping losses, and accelerating the piston/conrod mass after TDC/BDC.

The polar inertia of the engine rotating components can actually have a significant effect on the amplitude of both the torque and angular velocity fluctuations at the crank output. That's the primary reason recip piston engines use flywheels.

Accurately measuring variation in crank angular velocity on the dyno is fairly easy to do with modern data acquisition systems. A good optical encoder can easily give 1/2 deg resolution and that data can be sampled at frequencies well over 2000 kHz.

Regards,

slider

#82

Posted 17 April 2012 - 02:41

Great pic for sure! Only two possibilities.

1. Broken axle.

2. Open diff (Bad choice) or poor welding of differential gears.

gruntguru,

You forgot the third possibility: It's an example of the very exciting but short-lived form of motorsport known as "Top Fuel Short Oval Track Racing" (TFSOTR). The huge difference in rear tire diameter shown in the photo was intentional. It's called "stagger", and it helped the car handle better in the turns since TFSOTR rules required the cars to use a spool type rear end.

The most notable thing about the TFSOTR series was that the sanctioning body adopted the "European rotation standard", where the cars went around the track in a clockwise direction (turning right). Many say that the real reason TFSOTR never became popular was that most U.S. race fans felt racing clockwise was "un-American".

slider

#83

Posted 17 April 2012 - 05:53

But at 12,000 rpm G-Force rise to a con-rod snapping point and all those minute indifferences start to grow..it might come in micro time vibrations that won't show up on a dyno since it uccurs four more times than combustion pressure, twice per cycle per cylinder if it would be engine internal mass vibration off the crank, connection rod and piston combination like on the video I posted.An engine assembly can be 'motored' or spun without combustion to whatever the max fired rpm of the motor using a relatively very low powered electric motor. The torque required to free rotate an engine, which includes the effects of cranktrain inertia's due to layout and firing order, is almost nothing as compared to the torque the engine generates due to cylinder pressure.

#84

Posted 17 April 2012 - 06:16

Measuring TVs was my day job for a while. The effective resolution you can get even with a 60 tooth wheel is way better than what you quote, due to the wonders of Fourier analysis and FM demodulation. One of the most interesting books I ever read was Kerr Wilson, 3 volumes of TV analysis on things like Spitfire engines.Accurately measuring variation in crank angular velocity on the dyno is fairly easy to do with modern data acquisition systems. A good optical encoder can easily give 1/2 deg resolution and that data can be sampled at frequencies well over 2000 kHz.

#85

Posted 17 April 2012 - 06:58

#86

Posted 17 April 2012 - 11:38

GrpB,

During a complete engine cycle (ie. 720 deg in a 4-stroke) the torque produced about the crank axis by the piston is both positive and negative.

Regards,

slider

Must not have been clear, that was my entire point, torque at the crank is never constant, it is always accelerating/decelerating depending on # of cyls and firing order. GG says TF's have constant clutch slip with constant torque either side of the clutch, I say clutch slip is due to crank torque, since that is not constant in an IC engine the clutch slip must not be constant, as in a 4 stroke single cylinder engine which has clutch slip during firing (~180 deg) and no clutch slip for the rest of the cycle where torque is negative (~540).

Next, if it was minimzation of torque fluctuation due to inertial effect, the typical 180 deg crank throw I4 having all 4 pistons at BDC/TDC simultaneously as opposed to a 90 deg crank with only 2 at BDC/TDC at any time, GG's argument is that the torque fluctuation (at the crank) due to the odd firing order (pairs of cylinder firing close together instead of 4 even) is insignficant as compared to the minimized torque fluctation due to the inertial effect of the 90 deg crank. The idea that engine firing torque, several times the magnitude of torque consumed by changing inertial effect due to crank configuration, is not the overriding and significant factor between the two configurations doesn't jive.

Optical encoders are specialised equipment to most people outside of industry, OEM dyno development assumes crank optical encoders, aftermarket dyno development does not.

GG - if inertia has no effect on torque why argue the 'inertial oscillations' are the advantage of a 90 deg odd firing I4 over a 180 deg even firing I4? Sometimes you are saying torque is constant, sometimes not, sometimes inertia has an effect, sometimes not.

#87

Posted 17 April 2012 - 12:03

If by 4 cylinder you mean a traditional 4 in line without balancer shafts, then 2nd order vibration is the biggest contributor to block and head vibration and it generally is dominated by the inertial components at higher speeds. Whether TVs in particular show the same trend as the other vibrations I can't remember, but it seems likely. The proportion is that roughly out of 20g rms at 6000 rpm, 15g is inertial, the rest is gas forces. It may not be quite this proportion in TV because the 2nd order inertial is largely in the axis of the cylinders, gas forces tend to be less directional.Greg. Does your experience measuring TV's shed any light on the relative importance of inertial vs cylinder pressure excitation in 4cyl engines?

#88

Posted 17 April 2012 - 12:27

GrpB, it's quite simple what GG is saying- inertia has effect on torque amplitude, but being symmetrical about mean torque value does not affect mean value. Inertia has significant effect when accelerating/decelerating the engine- the engine with bigger amplitude oscillations due to inertia will consume bigger portion of developed torque to accelerate its own internals, thereby consuming torque that could have done a useful work.

#89

Posted 17 April 2012 - 14:35

It's called "stagger"

Bravo!

#90

Posted 17 April 2012 - 21:35

Thanks Greg, that settles it for me...

Actually, I did the graph on previous page because I saw something similar in a Uni textbook, and the difference between flat-plane and cross-plane inertia (and general shape of graphs) prompted me to do my own model to 'validate' it (I sort of couldn't see where this big difference was coming from, until I've done my model).

GrpB, it's quite simple what GG is saying- inertia has effect on torque amplitude, but being symmetrical about mean torque value does not affect mean value. Inertia has significant effect when accelerating/decelerating the engine- the engine with bigger amplitude oscillations due to inertia will consume bigger portion of developed torque to accelerate its own internals, thereby consuming torque that could have done a useful work.

Obviously, but consumed torque relates to traction, how, when the firing torque is orders of magnitude higher than inertial torque and the assertion is that closely grouping cylinder firings is trivial as compared to the inertial torque benefits which are miniscule in comparison? On your own graph if that is pistons only, add in the rest of the cranktrain, flywheel, clutch, geartrain inertias and what was 4x different torque fluctuation with piston only will become much smaller all told. The rods will probably have a real effect because they are much heavier but the heavy part is mostly rotating, not translating. So the inertia torque effects will be minimized to very small whereas the firing torque effects will remain very large, the bang-bang-bang-bang vs bangbang---bangbang, will be apparent clear as day.

I think I am not being clear in my posts, anyhow I have nothing really useful to add since all I have on the subject is theory which is worth as much as the effort spent to acquire it, I thought there were some motorcycle tire people on here and was hoping they would chip in. For me this is not a theoretical question like the hovering helicopter that is doing no work, at my novice racer/advanced trackday pace I have seen many more almost/full highsides from even firing I4’s than the big twins I ride. Granted, most race/track bikes are even firing I4’s which guarantees that most all highsides at the track are, yup, even fire I4’s. But anecdotally/subjectively my big twin gets great drive compared to I4’s, and I’m quite sure it is not due to rider skill or the skinflint in the fresh and sticky tire purchasing department (see: rider).

In dirt track various 90 and 60 deg Italian/Japanese big twins have been tried many times, with good riders but without success, against the 45 deg Harley motors. Always the same story, lots of power, no traction, even with the billet boat anchors they use (they call them ‘cranks’) to try to give them some inertia and tame them down. Maybe it is all baloney, but then motorcycling must be a deli, because there’s A LOT of bits of baloney laying around.

#91

Posted 17 April 2012 - 22:05

Obviously, but consumed torque relates to traction, how, when the firing torque is orders of magnitude higher than inertial torque and the assertion is that closely grouping cylinder firings is trivial as compared to the inertial torque benefits which are miniscule in comparison? On your own graph if that is pistons only, add in the rest of the cranktrain, flywheel, clutch, geartrain inertias and what was 4x different torque fluctuation with piston only will become much smaller all told. The rods will probably have a real effect because they are much heavier but the heavy part is mostly rotating, not translating. So the inertia torque effects will be minimized to very small whereas the firing torque effects will remain very large, the bang-bang-bang-bang vs bangbang---bangbang, will be apparent clear as day.

This part in bold is where you're wrong- just read Greg's last post if you need practical validation. And cross-plane I4 is not bangbang---bangbang, it's just that two bangs are more closely spaced than usual and two are further apart (it's not 180°-180°-180°-180° but IIRC 180°-90°-180°-270°).

#92

Posted 18 April 2012 - 00:10

Sure the clutch slip is not constant - but what varies is the relative velocity or "slip" - not the torque. A TF at the moment of launch is 100% slip - no chance of the clutch being in a stick-slip situation. Same applies for the first part of the run until just before the clutch is fully locked and there is probably a brief period of stick-slip as the clutch transitions to stick-stick (locked). Getting back to the first part of the run - if the clutch is constantly slipping, the torque will be proportional to coefficient of friction and clamping force, neither of which is oscillating.GG says TF's have constant clutch slip with constant torque either side of the clutch, I say clutch slip is due to crank torque, since that is not constant in an IC engine the clutch slip must not be constant,

Not sure which comments you are referring to but in essence:GG - if inertia has no effect on torque why argue the 'inertial oscillations' are the advantage of a 90 deg odd firing I4 over a 180 deg even firing I4? Sometimes you are saying torque is constant, sometimes not, sometimes inertia has an effect, sometimes not.

- slipping clutch = constant torque

- 4cyl engine = angular speed oscillations = torque oscillations.

#93

Posted 18 April 2012 - 00:23

Don't agree with the "consumption" argument. Inertia doesn't consume energy or torque, what is lost to inertia during part of the cycle is returned 100% during another.Inertia has significant effect when accelerating/decelerating the engine- the engine with bigger amplitude oscillations due to inertia will consume bigger portion of developed torque to accelerate its own internals, thereby consuming torque that could have done a useful work.

There is a direct relationship between angular speed variation, torque variation and kinetic energy of the pistons/small ends. Basically when all pistons are stationary (zero KE) all their KE has been transferred to the flywheel producing an increase in KE (and angular speed). Depending on driveline elasticities and inertias, this KE will be shared by masses throughout the system, with corresponding increases in torque throughout the system. What I am trying to say is, the amplitude of the inertial torque oscillation depends on all these factors since it begins life as an oscillating KE source.

#94

Posted 18 April 2012 - 01:10

* I'm no expert, as I've said many a time- but the way I figure it, let us compare, in that picture of mine, another red curve with bigger amplitude (representing inertia at higher revs). All other things being equal, the acceleration of engine internals will require energy equivalent to area between the new and old red curve in the first half-period of oscillation.

EDIT - to relate it to your comment about kinetic energy. The mechanism with bigger inertia will 'trap' more kinetic energy (kinetic energy being one half of inertia times angular speed squared*), so I went back to the model from which I got those graphs and in case of flat-plane vs. cross-plane configuration it turns out that inertia of oscillating masses in flat-plane engine is almost 60x bigger than with cross-plane (not only because of increased amplitude, but the frequency is halved as well)...

* or in case we're discussing, an area below one-half of period of the oscillation

Edited by Wolf, 18 April 2012 - 01:57.

#95

Posted 18 April 2012 - 02:29

#96

Posted 18 April 2012 - 05:25

Drivetrain TV is relevant to this discussion because periodic angular speed variation at the flywheel is the principal excitation for drivetrain TV and is also the phenomenon Yamaha were trying to eliminate with the cross-plane crankshaft.

Although it is reasonable to assume the flywheel is a TV node, I don't think measurements at the other end of the crank alone would yield an accurate TV trace due to the substantial speed variation at the flywheel - especially in 4 cyl engines.

#97

Posted 18 April 2012 - 12:09

I guess that is why dragsters have special tyres with liners etc these days. Plus bead locks.

What is the bet it turned the tyre on the rim and tore the valve out.

Though I do like the idea of top fuel oval track, that should be real fun!

Edited by Lee Nicolle, 18 April 2012 - 12:11.

#98

Posted 19 April 2012 - 06:07

Incidentally the measured level of TV may be of interest- typically at the crank nose it is 1-2 deg pk-pk, and can be reduced to less than half a degree with a decent TV damper. We assumed that the flywhel was nodal for TVs, I did measure it once using the starter ring gear as a toothed wheel, but i can't remmeber the result.

Greg Locock,

It takes a special kind of person to dedicate their professional career to an esoteric technical specialty like torsional vibration analysis. Don't get me wrong, as a mechanical engineer myself, I am truly impressed by anyone that sets their mind to becoming a world-class expert in these types of technical competencies. I do mechanical systems design for aircraft turbine engines, and I rely heavily on the analytical capabilities of a couple of specialists for things like shaft dynamics. I know little about structural dynamics and they know little about mechanical systems design. But working together we manage to resolve most potential system dynamic issues during the design process.

With the TV environment of recip engine crankshafts, the actual amplitude at nodal points like the crank snout or flywheel are not so important. Instead, what matters is the additional fatigue stress these dynamic effects create on the crank. The mode and energy of the crank response is important. The forcing frequency may produce a bending mode, or a torsional mode, or an axial mode. But if these coupled crank responses are not energetic or within the operating frequency of the engine, they are not normally of concern.

Regards,

slider

#99

Posted 19 April 2012 - 09:46

Greg Locock,

It takes a special kind of person to dedicate their professional career to an esoteric technical specialty like torsional vibration analysis.

Maybe, but that ain't me. If it is fitted to a car, and is greasy, oily or dirty, I've worked on it. Sometimes I've helped, sometimes I've thrown money at a non existent problem. I've designed 30c parts that save $100 recalls, I've reconfigured systems to save hundreds of dollars per car, and I've screwed up systems that cost $50 per car. Overall my bosses think I'm worth having around, but the only things I specialise in are thinking and messing about.

Advertisement

#100

Posted 19 April 2012 - 10:32