The photo above shows the cement used to plug oil holes drying on the shop wood stove, is one of many in a detailed

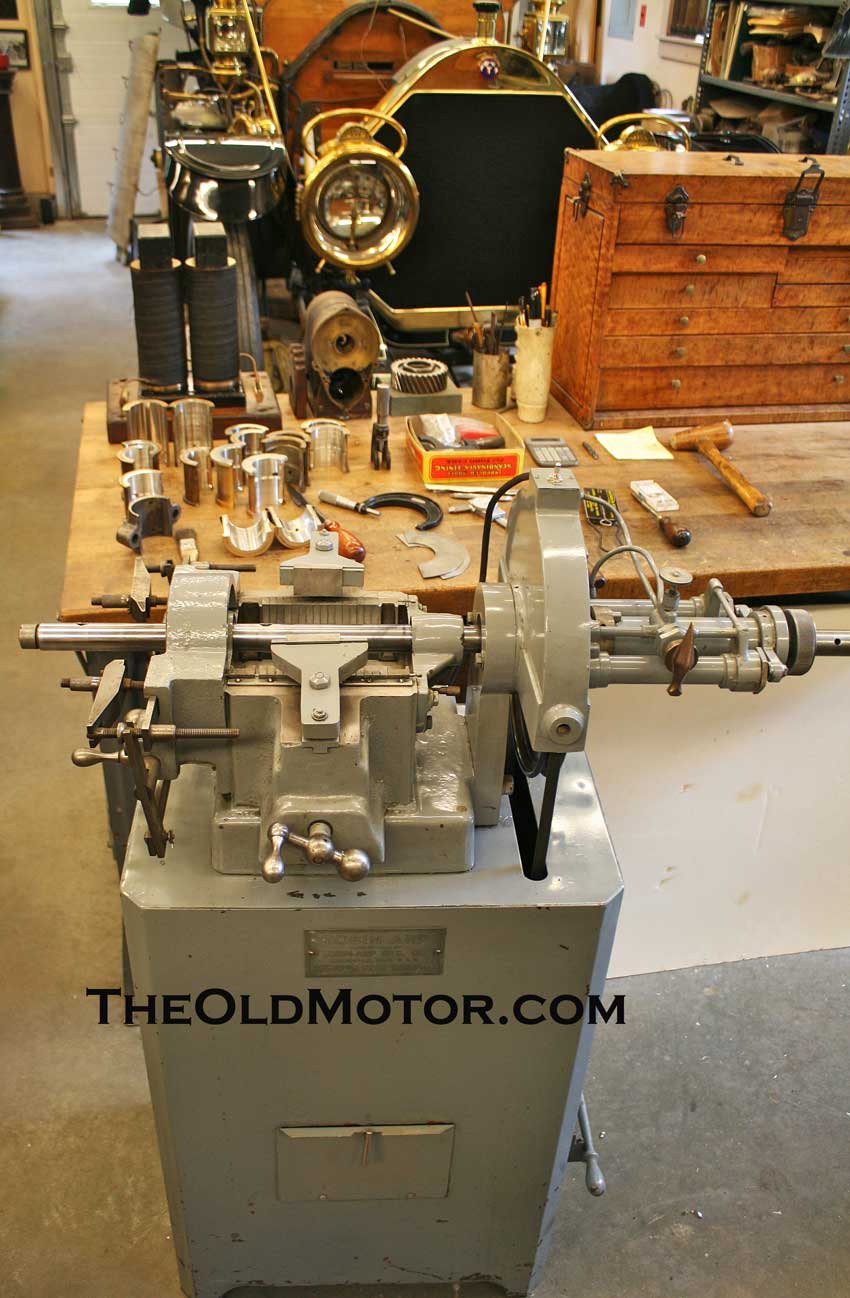

post all about how we pour babbitt. You can all learn all about how it is done in a post with multiple photos at The Old Motor.

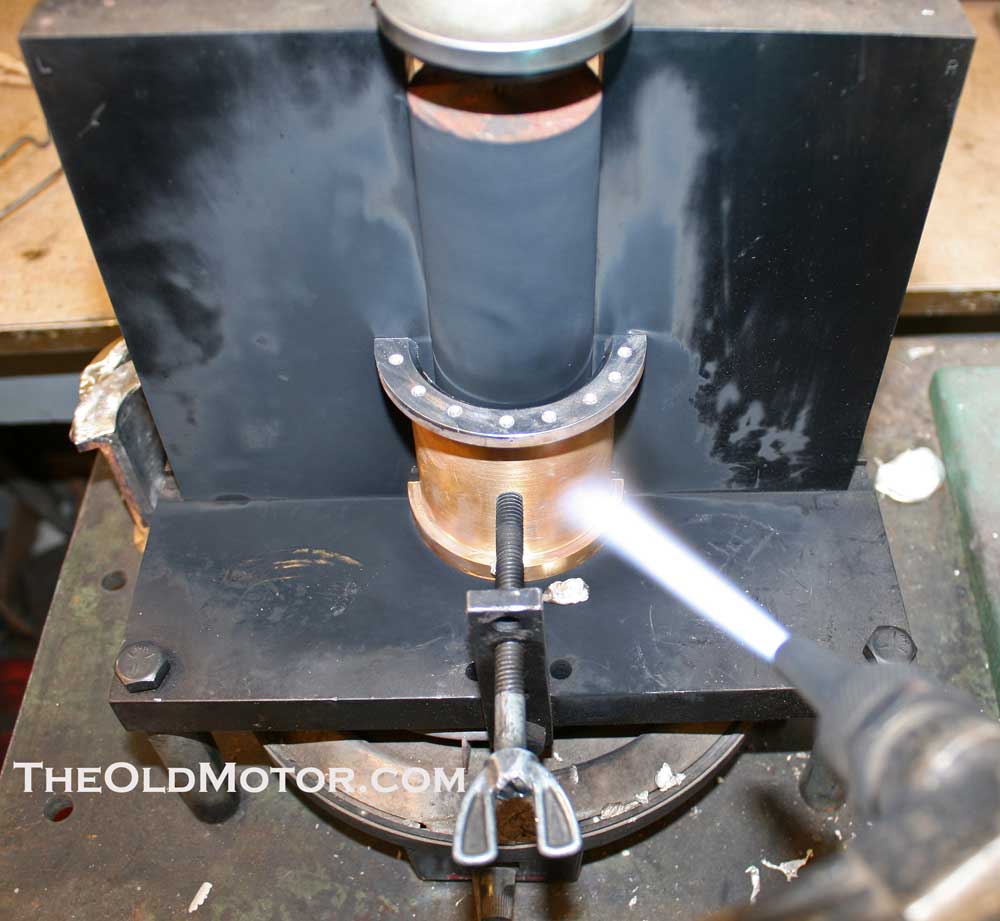

Below is a photo of melting out the old babbitt and at the bottom a new insert in the mould being heated before pouring.

Edited by THead, 09 May 2012 - 12:44.