Gray,

As a note, in practice Cal's bike at Talladega in 1971 turned 8400 RPM in forth gear with a 3.74 overall gear. For the race the gearing was changed to a 3.63 and maxed out at 7900 RPM in forth gear.

The cams that were run at the first three races in 1971 were modified Sifton ‘A’. As you already know, due to using two front heads, the cam lobes for the rear cylinder must be swapped. The original #1 exhaust now needs to be an intake and the original #2 intake now needs to be an exhaust. The Harley race department did this by copying the ‘A’ profiles switching intake and exhaust using their cam grinder for #1 and #2 cam gears.

A revised set of cams was used from the Kent, Washington race on, which included Talladega. I made this set of cams using four #3 Sifton ‘A’ front intake lobes. This changed the exhaust timing and lift as follows’.

Original Sifton ‘A’ Cam Timing

Intake Open 33 BTC Close 54 ABC Lift @ Valve .425” @ Tappet .300”

Exh Open 47 BBC Close 23 ATC Lift @ Valve .390” @ Tappet .276”

Change Cam Timing using four #3 Sifton Intake lobes

Intake Open 33 BTC Close 54 ABC Lift @ Valve .425” @ Tappet .300”

Exh Open 65 BBC Close 22 ATC Lift @ Valve .425” @ Tappet .300”Many people believed the 1971 factory iron engines suffered from the same heat problems that 1970 engines did and the alloy engines that came out in 1972 corrected this. The 1971 iron engine used what is called a Half Keystone top compression ring. This ring was designed for two stroke gasoline and diesel engines where ring sticking is a problem. The tapered side causes the axial clearance to vary as the ring moves radially, and thus reduces ring sticking. It seals extremely well (less then 1% blow-by) due to the combustion gas force acting on the tapered top surface as well as the back of the ring. The first 1972 alloy engines used this ring also and on the mile dirt tracks there would occasionally be the same rear piston problem that Cal's iron engine suffered at Talladega in 1971. The looseness that is good for keeping the ring groove clean is not reliable at high piston speeds. This was corrected by using a piston with a conventional rectangular top ring.

Harley learned an enormous amount from the two front head iron engine effort and applied this learning to the 1972 alloy engine.

I would like to commend you on your effort in duplicating this iron engine. I’ am not sure the readers of your post realize the enormous amount of work it takes to complete a project like this.

Well Done!

Ron

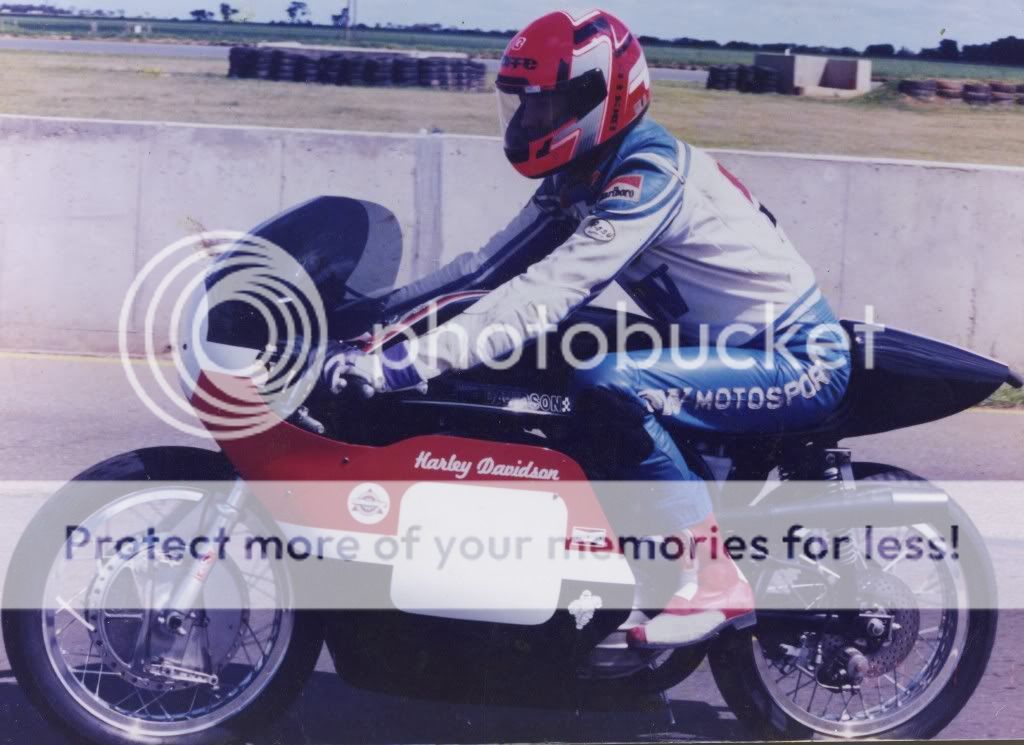

PS Here I am with Cal at Daytona on the alloy XR 750. I train my riders right!