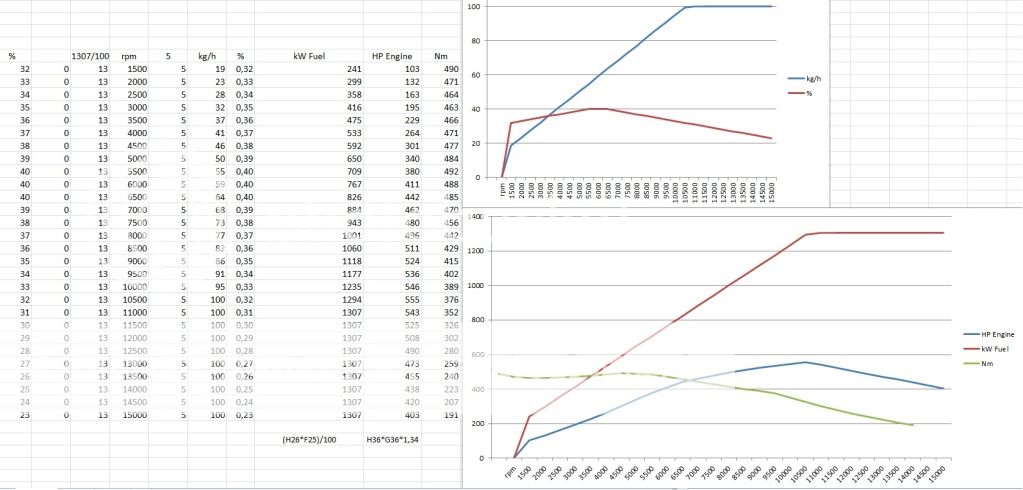

Todays 2.4 V8s will thus have 735 Hp, which I think is there or there-abouts?

Applied on a 620 Hp from a 1.6 liter turbo, the boost will vary from 1.17 (2.17 abs) at 10.5 to 0.52 Bar (1.52 abs) at 15 kRpm.

Is there really need for an intercooler at such a low boost?

First of all, with a boost as low as 0.5 to 1.0 Bar, inlet temperature will not be very high, making for a very inefficient intercooler.

Secondly, I fail to see how an intercooler will have a "propulsive effect" with these low temperatures and speed, teams like RedBull

is hard at work with reducing the drag of the water-radiators as it is, even eliminating the fins, running long profiled tubes only.

But there's also the packaging to consider, with the 2014 turbo location rules, an intercooler will make it a something of a mess.

I thought I'd better go back and check your assumptions.

The 2.17 number you quote is the DENSITY RATIO required for the 1.6T to make 620 hp @ 10.5 kRPM, assuming the same VE and TE as the 2.4 V8. The pressure ratio required to achieve this density ratio (at 80% compressor efficiency and no intercooling) is about 3.25 ie 3.25 bar abs boost. Discharge temperature is about 190*C.

With a typical intercooler, the pressure ratio required will be about 2.3 and compressor discharge temperature about 140*C.

The cars will need intercooling.

What sort of temperatures could you expect from 1 bar boost?

About 125*C

Edited by gruntguru, 11 October 2012 - 06:26.