Ford is releasing a flat-plane crank 5.2-liter V8 in the upcoming GT350.

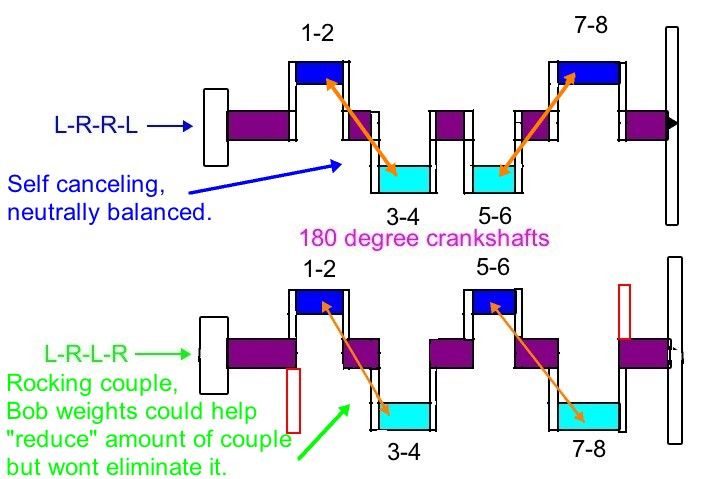

One curiosity about Ford's crank - the layout they're using is unusual. The throws do not have the usual inline-four-cyl-like "up down down up" pattern we're using to seeing in Ferrari and, well, any other flat plane crank V8 I can think of. Ford's crank is "up down up down". Are you visualizing this?

This results in a different firing order and sound... but it would seem to me to also have a negative effect on vibration. Namely it would introduce a first order rocking moment from end to end; something not found in the traditional FPC layout. Can anyone confirm that this would indeed be the case, or what's going on here?

Edited by Almag, 14 January 2015 - 23:24.