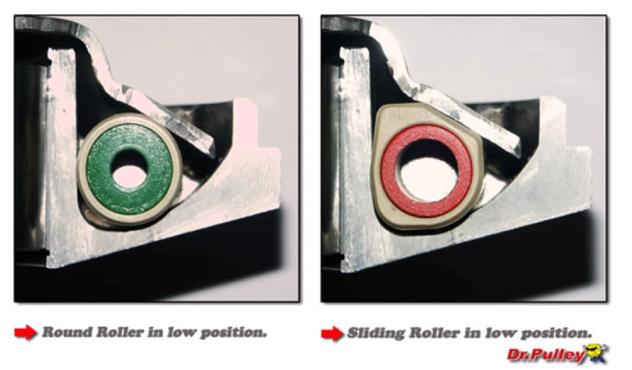

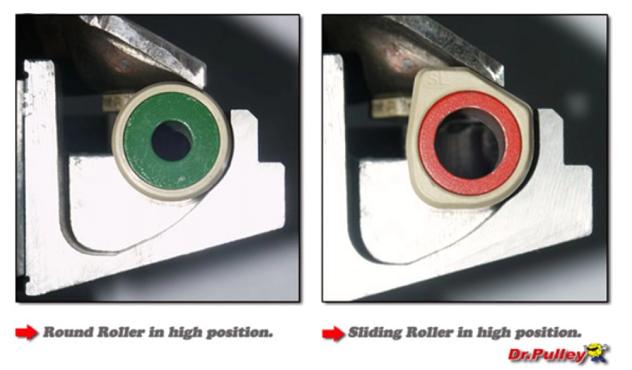

The conventional CVT variator (scooters, ATVs etc) comprises "centrifugal roller drive weights" like:

Despite their name and shape, these rollers, which bear significant loads, cannot help sliding on the ramps they abut on.

Sliding under load creates friction and causes wear.

The current way to reduce friction and wear is the use of low-friction self-lubricated nylon / plastic material.

What if instead of sliding, the rollers were true Rolling-Rollers?

This is what the PatRoR does.

In the following animation, the drive pulley is shown at three different ratios, a long (overdrive), a medium and a low.

Each Rolling-Roller comprises a pair of coaxial rollers (the one is a spool roller in this specific case) rotatably mounted to each other.

The relative rotation of the two rollers of each Rolling-Roller is shown:

In the following animation the drive pulley is at a low ratio:

or stereoscopically:

In the following animation the drive pulley is at a medium ratio:

In the following animation the drive pulley is at a high ratio (overdrive):

or stereoscopically:

Here is exploded a conventional drive pulley for CVTs:

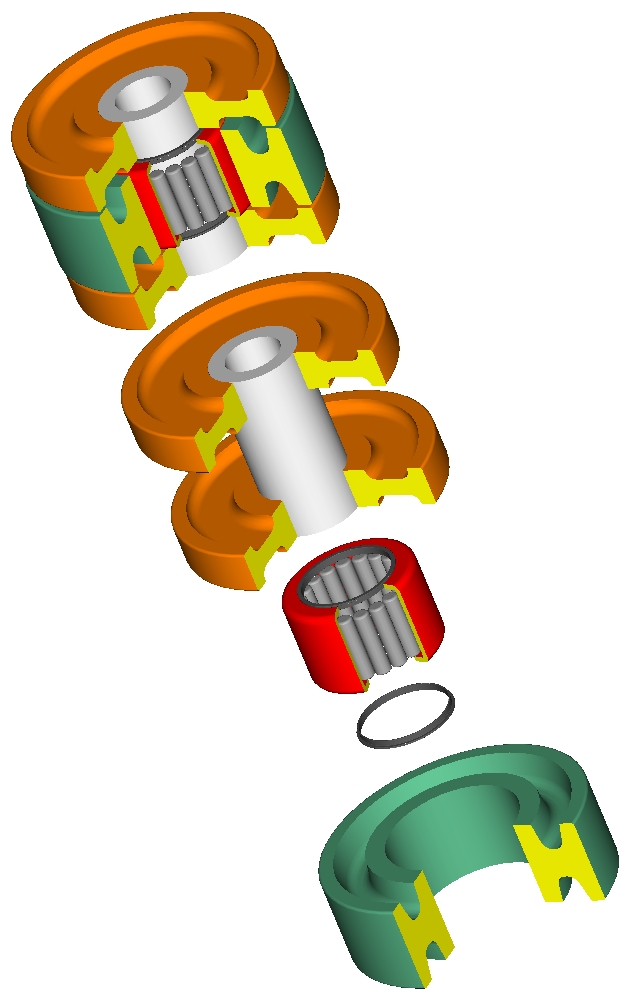

and here is the same drive pulley modified to PatRoR:

All it takes for the modification is the replacement of the sliding-roller-weights by Rolling-Rollers, and the machining of a groove on each ramp of the ramp plate (a work that requires neither accuracy nor special tools).

The PatRoR is the substitution of the conventional frictionfull sliding wedge by a frictionless rolling wedge.

Thoughts?

Objections?

Thanks

Manolis Pattakos