This post got me interested in brining back the topic

https://forums.autos...fset/?p=4484884 interesting graph and would like to discuss it as i find the pistons velocity and cylinder fill more akward than the graph presented

Offset Crank

#1

Posted 08 April 2020 - 04:48

Advertisement

#2

Posted 15 April 2020 - 16:23

I have checked the crank of my honda msx 125. and the offset at a quick measurement seems to be about 10% of the stroke 5 to 6 mm for a stroke of 57mm.

#3

Posted 07 May 2020 - 17:27

I have checked the crank of my honda msx 125. and the offset at a quick measurement seems to be about 10% of the stroke 5 to 6 mm for a stroke of 57mm.

thats interesting

little did i know the offset causes so much difference to the engine, it also increases the stroke for the same given crank as a normal alighned cylinder. it also extends the dwelling period in total, intake/power and shorten the time it does the compression/exhaust time. this means it would need a longer duration intake cam and shorter exhaust from the very basic point of view

also suspect because it has quicker movement on compression and exhaust stroke as the piston raises, it may suffer from higher secondary vibration

Edited by pierrre, 12 May 2020 - 07:12.

#4

Posted 09 May 2020 - 19:05

does anyone have an XL file or analysis program that you can input different offsets to see what happens to piston motion ?

https://benthamopen....TOMEJ-9-933.pdf

cheers Mal

#5

Posted 10 May 2020 - 00:27

They use a structural and inertial model of the piston in that paper because they are interested in impact forces and the like. As such a simple 1 dof excel model won't really produce all the pretty pictures. If you literally just want to see the effect of desaxe on the basic axial motion, yes I can put one together.

#6

Posted 10 May 2020 - 03:33

Hello Malbear

You write:

"does anyone have an XL file or analysis program that you can input different offsets to see what happens to piston motion ?"

Some years ago the following EXCEL file was prepared for someone who had similar questions:

https://www.pattakon...t_wrist_pin.xls

You can "play" with the EXCEL file to check and compare various cases.

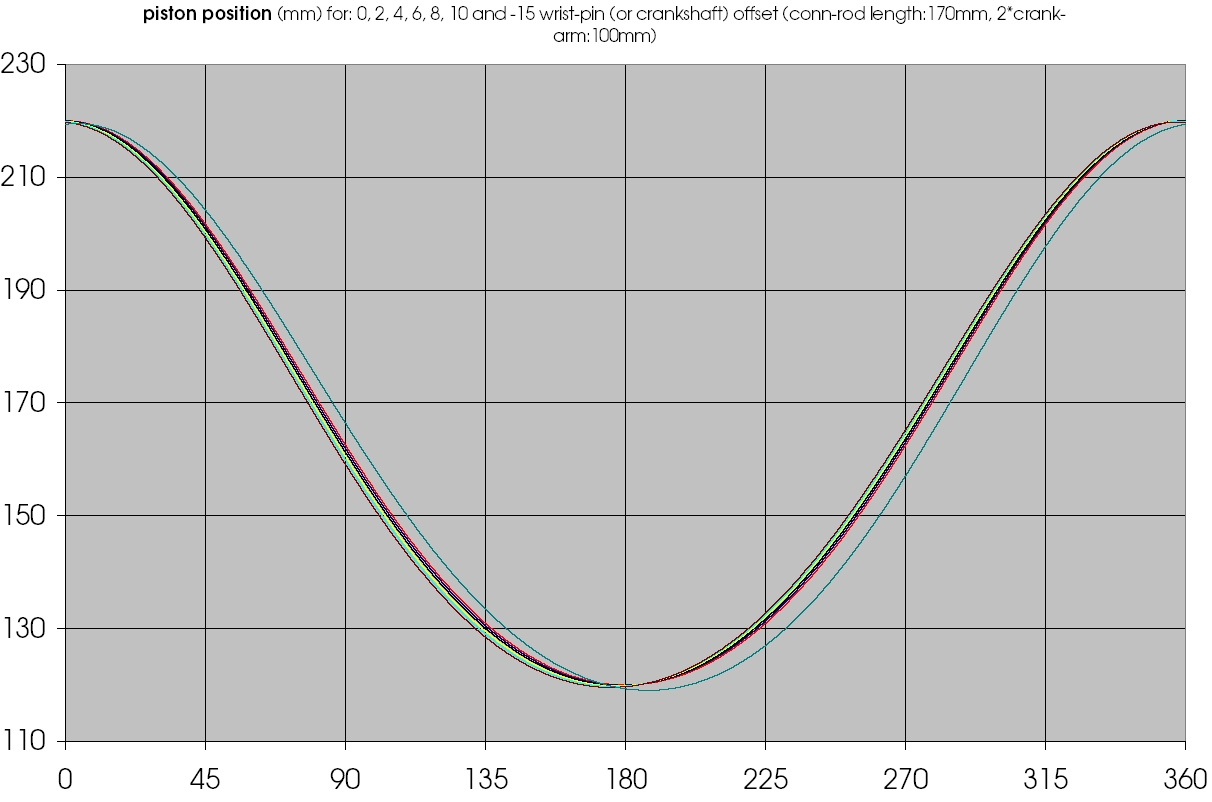

Here is the piston position along the cylinder axis versus the crankshaft angle:

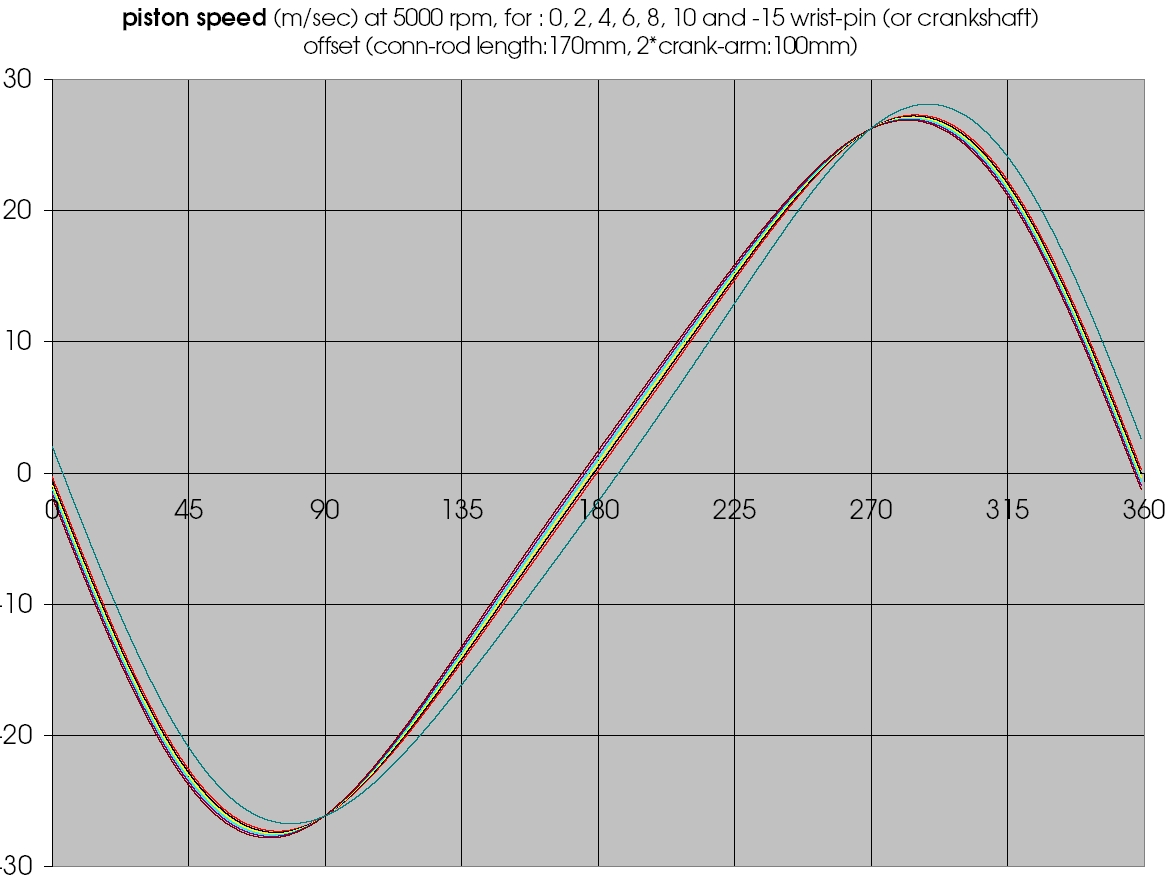

Here is the piston speed along the cylinder axis versus the crankshaft angle:

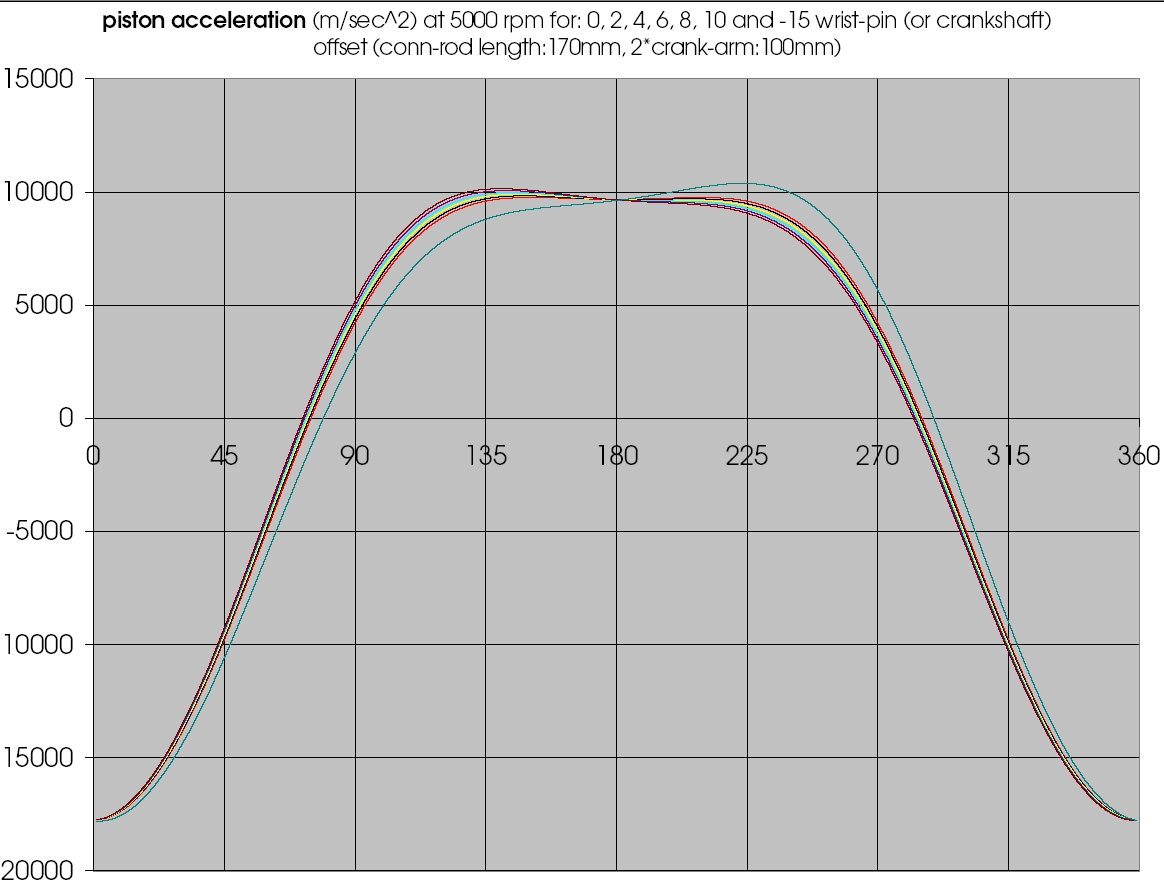

And here is the piston acceleration along the cylinder axis versus the crankshaft angle:

Worth to mention: an offset of the wristpin and an equal but opposite offset of the crankshaft axis is, for the geometrical motion of the piston along the cylinder axis, the same.

Thanks

Manolis Pattakos

Edited by manolis, 10 May 2020 - 04:04.

#7

Posted 10 May 2020 - 05:36

Thanks, didn't you also have a useful BASIC program for pistons?

#8

Posted 10 May 2020 - 06:43

Hello Greg.

Do you mean the "Balance" program https://www.pattakon...duc/balance.exe at https://www.pattakon...attakonEduc.htm ?

It was written in QUICK BASIC and runs in DOS environment.

It calculates the free inertia forces, moments and torques of any reciprocating piston engine arrangement (including the crankshaft balance webs and any external balance shaft(s)).

But I didn't put a "crankshaft offset" (or "wrist pin offset") in its parameters.

If I ever transfer the balance program to Visual Basic, the crankshaft (or wrist pin) offset will be added.

Thanks

Manolis Pattakos