The Block 8

#1

Posted 29 October 2010 - 07:40

Couple of problems, clutches are made to move 300kgs rather 1000kgs, same for the transmission, chain drive and no reverse.

We know there is a few V8's getting around that not only solve this problem but they also lighten your pocket by around $50,000USD

There is also the 4 cylinder case conversion that also solves all the problems and like the V8 you can bolt a normal RWD gearbox to it...

http://www.holeshot-...?page=h2-4-busa (you can find one of the V8's there as well)

So I was thinking, why not a "Block 8" in the same concept as the 4 above - a casing made to accept 2 x bike engine internals saving you a truck load of cash through not requiring special crankshaft and rods. A dummy output shaft would be required.

It would still be compact and lightweight, less vibes, management systems can still be rolled into one etc...

Am I missing something?

Advertisement

#2

Posted 29 October 2010 - 09:02

Am I missing something?

A diagram of the configuration you're talking about would be handy thanks.

#3

Posted 29 October 2010 - 09:41

Granted the weight will be slighly more than two heads on a V-8 block but the cost, complexity and deveopment time would be greatly reduced. Also the clutch problems mentioned by Cheapracer would be seriously reduced.

In simple terms you make the left hand engines ignition drive the right hand spark plugs and vice versa. It IS more complex than that but with modern ECU power and the availability of gearshifting actuators with millisecond response times and adjustable timing it should be do-able.

I know two engines are heavier but look at it this way, a superbike weighs about 190kg (or less) and can hit 180 mph. So if I just tied two together with tubes I get a four seater with near 180 mph speed and a weight of under 400kg for no design effort. Many bike engined cars get nowhere near 400kg with one bike engine let alone two so the idea of having two engines does not automatically mean extra weight

#4

Posted 29 October 2010 - 09:56

#5

Posted 29 October 2010 - 10:34

A diagram of the configuration you're talking about would be handy thanks.

Well it's no harder to imagine than 2 bike engines sitting next to each other but sharing the one block casting.

One head is turned 180 so that inlets are in the middle and exhausts to the outside of course.

I'm not looking for specifics of drive designs etc, I'm wondering about the big picture of the concept and also why hasn't it been done before?

#6

Posted 29 October 2010 - 10:48

#7

Posted 29 October 2010 - 10:49

I have often idly wondered why you cannot make a "bike V-8" simply by using two std. bike engines each driving one rear wheel through the bike transmission and synchronised via the ECU.

You can run them separate that way just include a jack shaft to join them that includes an LSD.

One idea I have had for years is to put 2 side by side onto a jackshaft then drive from the jackshaft to the diff.

To resolve the firing issue whereas one point you may have a big bang 4 (both engines firing at the same time) and the next point you have an 8 cylinder with the engine firing alternately which may give car instability and I have heard breaks crankshafts, I would use RCG random chaos gearing ™ in that I would have slightly different gearing to the jackshaft so one engine runs up about 500 rpm compared to the other giving a cross over of the big bang 4 and normal sequence 8 cyls firing 10 times a second to smooth it all out.

#8

Posted 29 October 2010 - 11:14

Or you could just leave out some of the catastrophic design errors made in the BRM (H16 I'm sure you meant).I think the layout requires a geared crank ( if I have got it right). If so, geared cranks have had problems in the past like the 1966 BRM flat 16 which was heavy and plagued by vibratons. They have also worked fine on big rail diesel engines ( Sulzer 2,500 bhp twin sixes) so maybe the rev range and frequencies are key.

#9

Posted 29 October 2010 - 11:15

I would use RCG random chaos gearing ™ in that I would have slightly different gearing to the jackshaft so one engine runs up about 500 rpm compared to the other giving a cross over of the big bang 4 and normal sequence 8 cyls firing 10 times a second to smooth it all out.

OMG!

#10

Posted 29 October 2010 - 11:46

Or you could just leave out some of the catastrophic design errors made in the BRM (H16 I'm sure you meant).

Of course he meant the H16 but what do you mean by the design errors....?

OMG!

Yes my Son?

Edited by cheapracer, 29 October 2010 - 11:47.

#11

Posted 29 October 2010 - 12:42

Recognition at last, cheapy!Yes my Son?

#12

Posted 29 October 2010 - 13:02

Motorcycle engines are a source of lightweight big hp for cars as some of you are aware.

Couple of problems, clutches are made to move 300kgs rather 1000kgs, same for the transmission, chain drive and no reverse.

We know there is a few V8's getting around that not only solve this problem but they also lighten your pocket by around $50,000USD

There is also the 4 cylinder case conversion that also solves all the problems and like the V8 you can bolt a normal RWD gearbox to it...

http://www.holeshot-...?page=h2-4-busa (you can find one of the V8's there as well)

So I was thinking, why not a "Block 8" in the same concept as the 4 above - a casing made to accept 2 x bike engine internals saving you a truck load of cash through not requiring special crankshaft and rods. A dummy output shaft would be required.

It would still be compact and lightweight, less vibes, management systems can still be rolled into one etc...

Am I missing something?

Like an Ariel Square Four?

#13

Posted 29 October 2010 - 14:07

Like an Ariel Square Four?

buzzzzz, sorry contestant one, that is not the correct answer.

An Ariel Square 4 has just one crankshaft. This concept is 2 engines hugging in the same bed.

#14

Posted 01 November 2010 - 07:36

buzzzzz, sorry contestant one, that is not the correct answer.

An Ariel Square 4 has just one crankshaft. This concept is 2 engines hugging in the same bed.

I thought the Ariel Square Four had two crankshafts?

#15

Posted 01 November 2010 - 09:18

ps. I love the RCG concept!

#16

Posted 01 November 2010 - 14:28

I thought the Ariel Square Four had two crankshafts?

Let it be known I get my info PM'ed from Tony Mathews, how is could it be explained?

as did the Suzuki RG500 road bike and their Gamma GP bikes.

ps. I love the RCG concept!

But that I did know!!

Edited by cheapracer, 01 November 2010 - 14:31.

#17

Posted 01 November 2010 - 14:33

So, what does 'worked on' mean in your book, cheapy? Kicked the tyres?

My apologies Sir, you are indeed correct - Humurous considering I have worked on a few of them (obviously never actually stripping a engine down, I probably would have noticed

)

Not me then, with that spelling.Let it be known I get my info PM'ed from Tony Mathews, how is could it be explained?

#18

Posted 01 November 2010 - 15:51

So, what does 'worked on' mean in your book, cheapy? Kicked the tyres?

Not me then, with that spelling.

As I have mentioned before I did a stint restoring Trumpys, Beesas and Nortons for a shop and since I was also the licenced RWC guy I got to do odd jobs on all sorts of weird Brit bikes as well as others.

Never forget the guy who bought in his prized Sunbeam 500 on a trailer for a RWC -

"You have to take it off the trailer Mate"

"Why you can see it's perfect"

"Maybe but I got to do a few checks such as steering head bearings"

"Well ok but I'm not happy"

"Ok, seems fine, now I'll have to test ride it around the block"

"WHAT??? No way in the world is anybody going to ride this bike"

"ok have it your way...."

Had a Ducati 916 owner exactly the same he he.

Fun times but I had to go back to making real money myself.

#19

Posted 01 November 2010 - 19:35

Well it's no harder to imagine than 2 bike engines sitting next to each other but sharing the one block casting.

One head is turned 180 so that inlets are in the middle and exhausts to the outside of course.

I'm not looking for specifics of drive designs etc, I'm wondering about the big picture of the concept and also why hasn't it been done before?

for me, as a bike engine in a lightweight car user (ok, future user the car is not finished yet..

if you delete the gearbox, and want to use twin bike engines on the comon block, you need to do a new crankcase anyhow, as crankcases are a part of the whole combo, so you might just as well make a new crankshaft and end up with a custom V8, instead of a paralel 4 with twin bike cranks.. I think the total cost is similar..

Advertisement

#20

Posted 03 November 2010 - 03:03

for me, as a bike engine in a lightweight car user (ok, future user the car is not finished yet..

), 50% of the attraction is in the sequential dogbox that comes attached to the bike engine.. so I do not find much interesting in using a bike engine driving a car gearbox..

if you delete the gearbox, and want to use twin bike engines on the comon block, you need to do a new crankcase anyhow, as crankcases are a part of the whole combo, so you might just as well make a new crankshaft and end up with a custom V8, instead of a paralel 4 with twin bike cranks.. I think the total cost is similar..

New block is relatively easy for Busa base because they come with separate cylinder blocks anyway so it's just a crankcase literally that you need.

If you go to crank then it becomes very difficult and costly (as well as new rods), crank design is not as simple as it may seem on the surface and thats before the harmonics that have killed many an attempt.

The whole idea was to keep it as cheap as and I can't see an easier way to get big lightweight hp - 150kgs running for 360 standard hp ain't too bad.

If you're lazy you can buy sequential gearboxes around the place such as Holinger, Albins etc.

#21

Posted 03 November 2010 - 03:38

New block is relatively easy for Busa base because they come with separate cylinder blocks anyway so it's just a crankcase literally that you need.

If you go to crank then it becomes very difficult and costly (as well as new rods), crank design is not as simple as it may seem on the surface and thats before the harmonics that have killed many an attempt.

The whole idea was to keep it as cheap as and I can't see an easier way to get big lightweight hp - 150kgs running for 360 standard hp ain't too bad.

If you're lazy you can buy sequential gearboxes around the place such as Holinger, Albins etc.

I hate to say it, but this is starting to look like a reasonable idea - certainly simpler than a motorcycle-based V-8.

Holingers cost about a million dollars each - motorbike gearboxes are free with the engine.

#22

Posted 03 November 2010 - 03:55

I hate to say it, but this is starting to look like a reasonable idea - certainly simpler than a motorcycle-based V-8.

Holingers cost about a million dollars each - motorbike gearboxes are free with the engine.

After I get some other projects underway with a company I work with now, I am fairly confident they will do a proto for me - they certainly have the machinery I need to do it and the 5 axis mill head arrives soon.

Bike boxes are chain drive (the desirable engines) and have no reverse and of course are very limited to how much hp/weight they will push including their clutch. Their orientation and fitting is also less than desirable.

Small Holingers are slowly becoming affordable as they are becoming more common on the market - a Mate of mine has 4 for sale right now, 2 sequentials and 2 H patterns and the H can be converted for the lazy. There are plenty of $100 gearboxes as well to suit such as Toyota W55 type series.

#23

Posted 03 November 2010 - 04:13

After I get some other projects underway with a company I work with now, I am fairly confident they will do a proto for me - they certainly have the machinery I need to do it and the 5 axis mill head arrives soon.

Bike boxes are chain drive (the desirable engines) and have no reverse and of course are very limited to how much hp/weight they will push including their clutch. Their orientation and fitting is also less than desirable.

Small Holingers are slowly becoming affordable as they are becoming more common on the market - a Mate of mine has 4 for sale right now, 2 sequentials and 2 H patterns and the H can be converted for the lazy. There are plenty of $100 gearboxes as well to suit such as Toyota W55 type series.

I think new Holingers are $20,000+ but I may be wrong.

The main problem with your "U" engine (which, I think, is what they are normally called) would seem to be finding a simple way of coupling the two engines together and then to a single output shaft so that a conventional clutch and gearbox can be used.

#24

Posted 03 November 2010 - 04:51

I think new Holingers are $20,000+ but I may be wrong.

The main problem with your "U" engine (which, I think, is what they are normally called) would seem to be finding a simple way of coupling the two engines together and then to a single output shaft so that a conventional clutch and gearbox can be used.

Busa has a very strong large diameter drive gear on the crank so you would have the 2 cranks with an intermediate gear between them hooked to a dummy shaft to drive the flywheel. This shaft could be used as a balance shaft if required.

The thinner gear in the middle drives the Busa balance shaft...

#25

Posted 03 November 2010 - 06:43

Busa has a very strong large diameter drive gear on the crank so you would have the 2 cranks with an intermediate gear between them hooked to a dummy shaft to drive the flywheel. This shaft could be used as a balance shaft if required.

The thinner gear in the middle drives the Busa balance shaft...

That should work - and the two engines will both turn the same way then.

I haven't noticed any missing relatives.

#26

Posted 03 November 2010 - 10:56

#27

Posted 03 November 2010 - 11:57

Some kind lad in another forum even laid out 2 'Busa blocks (to compare old and new) for me, mighty sporting of them ....

The two blocks could be angled outwards in a "V" (still with two cranks etc.) to give more space between for the manifolds etc. - like the "Busa V-8s.

#28

Posted 03 November 2010 - 13:32

The two blocks could be angled outwards in a "V" (still with two cranks etc.) to give more space between for the manifolds etc. - like the "Busa V-8s.

It's still a lot of trouble to go to, so why not just make it a V8 from the start? It's a known thing and they work very well indeed. More compact, less weight, fewer parts, etc.

#29

Posted 03 November 2010 - 14:05

It's still a lot of trouble to go to, so why not just make it a V8 from the start? It's a known thing and they work very well indeed. More compact, less weight, fewer parts, etc.

You may have missed the point "Steve", money. This is a poor man's way to go about it.

How about I supply a cheap block and basic requirement then you go out and pick up a couple of second hand Busa engines and stick it all together yourself.

Of course the V8 has all those advantages of which you pay through the teeth for, $50,000USD for the Hartley for example and guess the Powertech is similar and I don't have time or knowledge to develop a crank that may be a piece of crap anyway and end the project.

I may roam Moss st next month when I'm back and see if theres a couple of dead cranks around to take back with me and play.

In the meantime heres another way one guy has modded a Busa for normal RWD gearbox work, quite clever actually and worthwhile read ...

http://www.motoiq.co...e-thinking.aspx

#30

Posted 04 November 2010 - 03:38

You may have missed the point "Steve", money. This is a poor man's way to go about it.

How about I supply a cheap block and basic requirement then you go out and pick up a couple of second hand Busa engines and stick it all together yourself.

I can't see it being so much cheaper to be worth all that mucking around sorry.

#31

Posted 04 November 2010 - 16:51

but stick to the bike box internals.. the hayabusa box looks to be able to take 500hp or so.

Might have chanced some internals tho..

when it comes to reverse i have belief in that you could design inn that somehow.

heck i could even draw in that myself on the CAD if i had all the measurements on the standard parts.

Edited by MatsNorway, 04 November 2010 - 16:52.

#32

Posted 04 November 2010 - 17:16

I can't see it being so much cheaper to be worth all that mucking around sorry.

As I said I don't believe the course of developing a crankshaft is a cheap one or a safe bet, I cant design it myself, clueless about balancing and harmonics etc. even though I can get them made 10mins up the road for cheap by these guys .... http://www.scxinkun.com/products.asp

However if someone sent me a Busa V8 as a sample ...... please?

But then what about the repair bill for special items such as that crank and the rods that go with it, with my idea after that blow up you just pop down to the wreckers and get a good second hand crank and a couple of rods and on your way again. You know well that buying anything for racing is only the start of the costs.

#33

Posted 04 November 2010 - 17:22

but stick to the bike box internals..

Busa box can not take 500hp in a sticky tyre, heavy race car situation. I must admit they handle smaller competition car situations quite well though such as Locosts with up to 1600cc and 250hp, Suzuki certainly over engineered them.

You still have the fitment problem too.

#34

Posted 04 November 2010 - 18:56

Busa box can not take 500hp in a sticky tyre, heavy race car situation. I must admit they handle smaller competition car situations quite well though such as Locosts with up to 1600cc and 250hp, Suzuki certainly over engineered them.

You still have the fitment problem too.

add a torque adjusted slipper clutch.

what fitment?

Edited by MatsNorway, 04 November 2010 - 19:00.

#35

Posted 04 November 2010 - 20:55

http://www.youtube.c...feature=related

this guy was driving regularly on different meetings. Turbo and everthing. And thats not a busa box.

http://www.situne.no/

Anyway. would be cool to keep the original car box and just slam in this U8 motor of yours.

I would have kept separate chain drives on them, if one fails the other one is still salvageable possibly.

Edited by MatsNorway, 04 November 2010 - 21:08.

#36

Posted 04 November 2010 - 21:58

Even just for the sound alone.

#37

Posted 05 November 2010 - 02:50

How about 2 V4 ducati engines inline? Are these motogp only or is there a version available to the public?

Even just for the sound alone.

Slightly out of the desired price range. A Busa will cost you 2 to 3 grand for a good used running engine, others are cheaper and I'm sure even an old 916 engine would hurt the wallet.

One of the reasons I have decided to develop in China in these areas is I have a desire to bring the cost of motor racing to a reasonable level but still at an exciting pace. Miata's, the most popular racing series in America and while no doubt fun are not for me.

I am trying to work out what I can build at a real budget racers level including the much more important on going costs, there is no point owning a competition car that you can not afford to repair and or maintain.

The first line is the "cheap racer" cars which are drawing closer daily and if successful with the company I am working with now, who will produce them, I will have some sizable resources to dip into for expansion next year.

#38

Posted 05 November 2010 - 09:48

Slightly out of the desired price range. A Busa will cost you 2 to 3 grand for a good used running engine, others are cheaper and I'm sure even an old 916 engine would hurt the wallet.

One of the reasons I have decided to develop in China in these areas is I have a desire to bring the cost of motor racing to a reasonable level but still at an exciting pace. Miata's, the most popular racing series in America and while no doubt fun are not for me.

I am trying to work out what I can build at a real budget racers level including the much more important on going costs, there is no point owning a competition car that you can not afford to repair and or maintain.

The first line is the "cheap racer" cars which are drawing closer daily and if successful with the company I am working with now, who will produce them, I will have some sizable resources to dip into for expansion next year.

What are these "cheap racers" basically like? Single-seater open wheelers? 2-seat small sports cars? Or something else?

#39

Posted 05 November 2010 - 11:25

Maybe a requirement that tyres last five or six meetings? No buffing, of course.

Clubman style cars were always the most economical cars for their speed.

Advertisement

#40

Posted 05 November 2010 - 12:51

What are these "cheap racers" basically like? Single-seater open wheelers? 2-seat small sports cars? Or something else?

Yes to all 3, you just about described all 3 models in one sentence. You will all know in a couple of weeks

#41

Posted 10 November 2010 - 16:20

Here is 2 American Bantam engines stitched together in the exact way I propose the Block 8 dummy shaft and all ... it's got 2 whole engines in there, 2 cranks and all...

1938!!

Edited by cheapracer, 10 November 2010 - 16:25.

#42

Posted 11 November 2010 - 01:59

As my Dad always says to me - "It's been done".

Here is 2 American Bantam engines stitched together in the exact way I propose the Block 8 dummy shaft and all ... it's got 2 whole engines in there, 2 cranks and all...

1938!!

The Austin Seven (Bantam) had separate cylinder blocks like most motorcycles. Your Dad was pretty much right.

#43

Posted 11 November 2010 - 12:20

The Austin Seven (Bantam) had separate cylinder blocks like most motorcycles. Your Dad was pretty much right.

Those pictures have actually inspired me to approach some people to have a go at this, hell if some dude can do it in 1938 why can't I with the equipment and resources that surround me!

My Dad's a clever guy and has been around a long time and worked on all sorts of interesting stuff from Jet cars to F5000's, used to help out at Phil Irving's workshop on occasion (watched the first Repco Brabham being built occasionally).

#44

Posted 12 November 2010 - 02:25

Those pictures have actually inspired me to approach some people to have a go at this, hell if some dude can do it in 1938 why can't I with the equipment and resources that surround me!

My Dad's a clever guy and has been around a long time and worked on all sorts of interesting stuff from Jet cars to F5000's, used to help out at Phil Irving's workshop on occasion (watched the first Repco Brabham being built occasionally).

Early Austin Seven engines only had a roller bearing at each end of the crankshaft. This would make the job of making a crankcase a lot simpler. I have no idea what the Bantam bearing arrangement would be.

Making a crankcase for a Hayabusa would be a lot trickier - would you have two separate oil pumps and oil circulation systems? Ignition system(s)? etc.?

#45

Posted 12 November 2010 - 04:24

My Dad's a clever guy and has been around a long time and worked on all sorts of interesting stuff from Jet cars to F5000's, used to help out at Phil Irving's workshop on occasion (watched the first Repco Brabham being built occasionally).

Does he know Adrian Brooke?

#46

Posted 12 November 2010 - 10:19

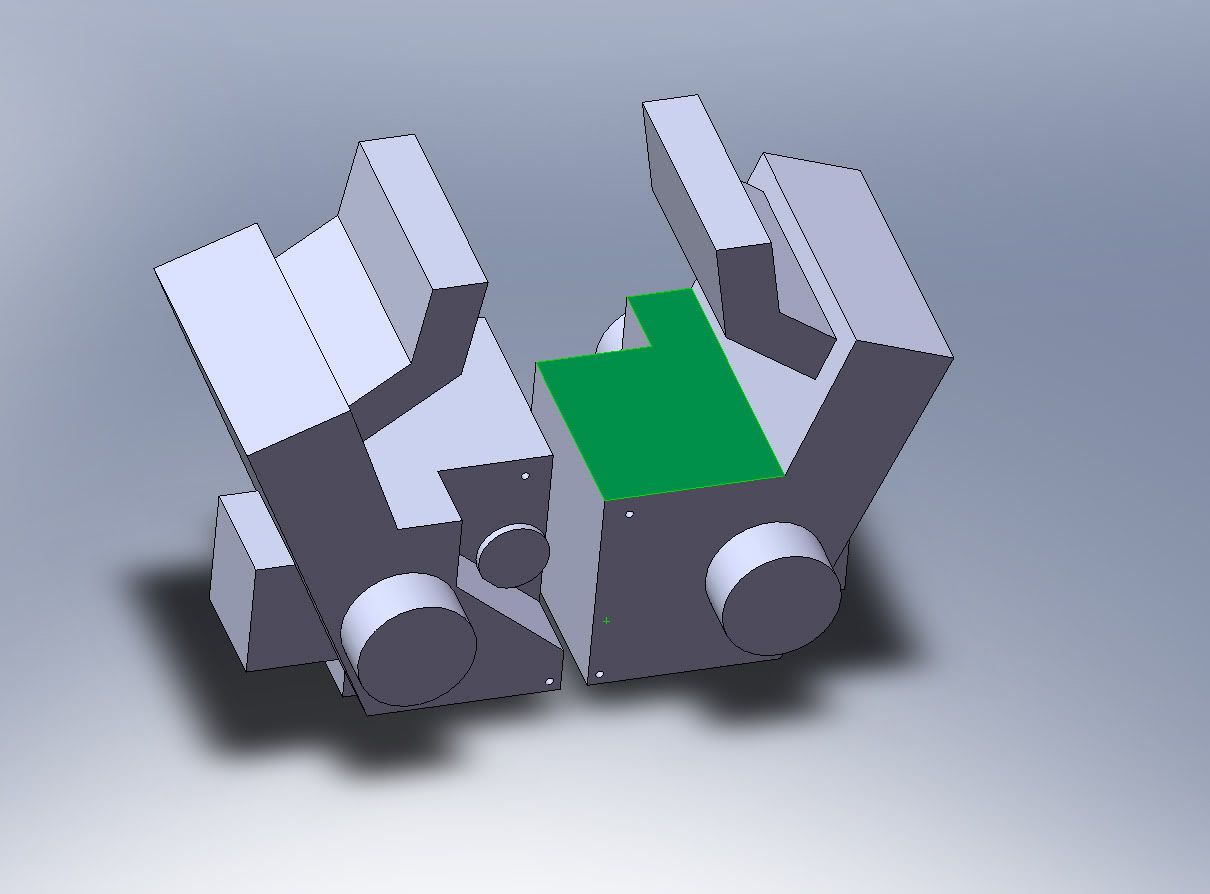

something like this:

and then the shaft goes direct into a diff...

it is probably too wide for a front engine aplication, and not as elegant as your idea, but should work as a mid engine setup.. dog boxes and all..

#47

Posted 12 November 2010 - 19:50

http://archive.pepub...34825046739631/

which describes the in service experince on the Sulzer twin 6 rail diesel engine. These were the most widely used engine on the UK railways for many years. It used a welded up crankcase ( as did other big rail diesel engines)

#48

Posted 12 November 2010 - 23:57

One of the reasons I have decided to develop in China in these areas is I have a desire to bring the cost of motor racing to a reasonable level but still at an exciting pace. Miata's, the most popular racing series in America and while no doubt fun are not for me.

So why notadapt the Hyabusa engine to a car gearbox and turbo or supercharge the engine? Surely cheaper than making a new crankcase?

If you must have an 8, is it possible to make a horizontally opposed 8, using the standard 'Busa crank? You'd have to use new rods in a master and slave arrangement, or use a scotch yoke type arrangement.

Just wondering if the crank is up to it, and if the oil system would still work.

And if it did, you could always make an H16....

#49

Posted 13 November 2010 - 17:59

So why notadapt the Hyabusa engine to a car gearbox and turbo or supercharge the engine? Surely cheaper than making a new crankcase?

If you must have an 8, is it possible to make a horizontally opposed 8, using the standard 'Busa crank? You'd have to use new rods in a master and slave arrangement, or use a scotch yoke type arrangement.

Just wondering if the crank is up to it, and if the oil system would still work.

And if it did, you could always make an H16....

I like the idea of a Boxer 8.

It might even fit nicely down there too. and if you dont charge it there will be no probem to make it last.

#50

Posted 15 November 2010 - 09:29

Making a crankcase for a Hayabusa would be a lot trickier - would you have two separate oil pumps and oil circulation systems? Ignition system(s)? etc.?

No, single systems

Does he know Adrian Brooke?

Dunno, will ask next time I talk to him.

So why notadapt the Hyabusa engine to a car gearbox and turbo or supercharge the engine? Surely cheaper than making a new crankcase?

This Guy did a good job of that but it still won't sound like a Ford DFV ;)

http://www.motoiq.co...e-thinking.aspx

cheapy, you gave me another idea... why not stick two bike engines togeather, end on end, forming a WIDE "V8" togeather with twin gearboxes...

Because you still have the "2 separate engine" problems such as when they fire compared to each other.

Edited by cheapracer, 15 November 2010 - 09:32.