The “cylinder lubrication problem” is described in details by Ole Christensen of Wartsila, in their Technical Journal of February 2010 at http://www.pattakon....nal_02_2010.pdf

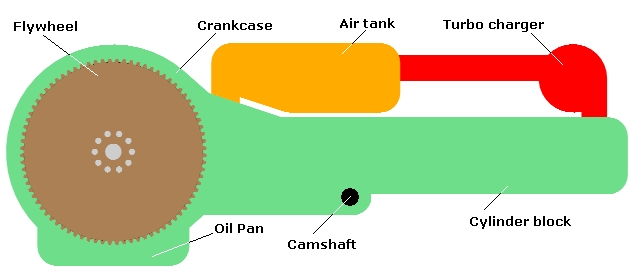

(above is the s35 (i.e. 350mm bore), the smallest low-speed direct-drive 2-stroke marine engine of MAN)

Besides being the maker of the world’s most powerful medium speed 4-stroke engine (Wartsila-64, 2.000 KW per cylinder), Wartsila – Sulzer is also a maker of the giant two-stroke marine and power-station direct-drive low-speed engines.

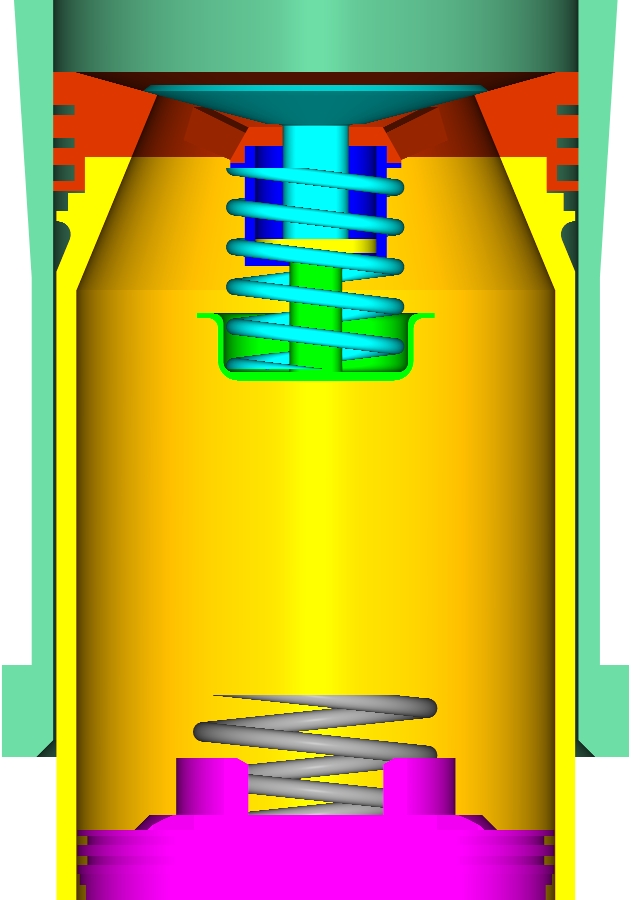

The PatMar(ine) (or PatMar) at http://www.pattakon....takonPatMar.htm is through scavenging and at the same time its cylinder liner is rid of ports.

The combustion chamber of the PatMar is as rid of lubricating oil (and oil mist) as the best four stroke marine engines.

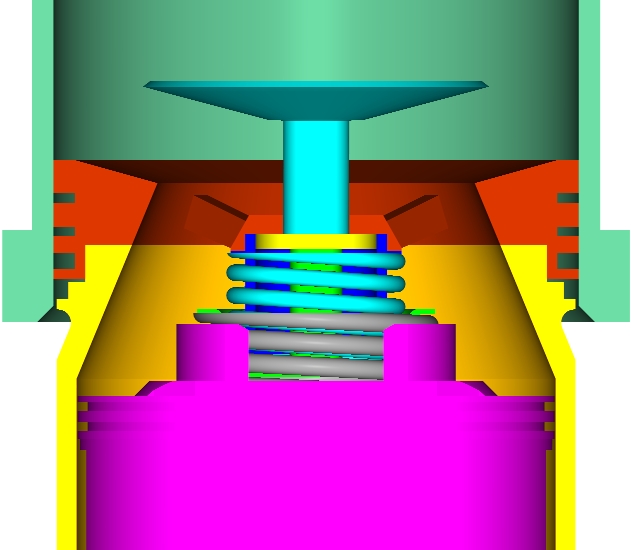

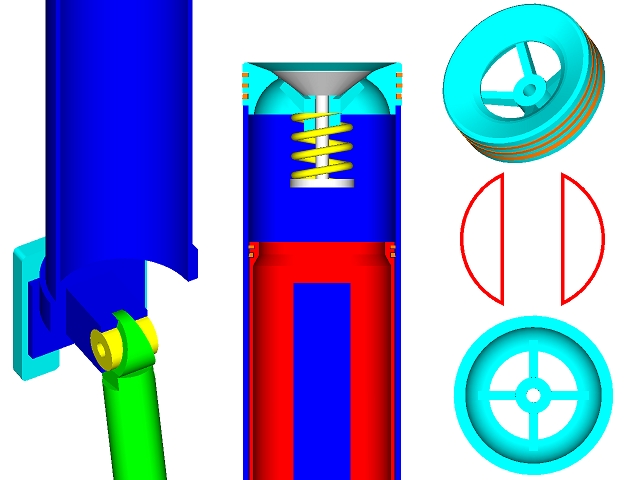

The PatMar can be made with one exhaust valve (on the cylinder head) and one inlet valve (on the piston crown) per cylinder.

The PatMar can be made with four exhaust valves (on the cylinder head) and another four intake valves (on the piston crown) per cylinder.

And so on.

That is, neither the combustion chamber shape, nor the injector(s) location, are worse than those in the 4-stroke of similar bore. On the contrary, the cross-head architecture enables extreme “stroke to bore” ratios (like 4.5), which gives way more “compact” combustion chamber with lower surface to volume ratio than in the four-stroke of same capacity per cylinder.

For instance:

The 4-stroke Wartsila 64 has 640mm bore and 960mm stroke.

A PatMar can be made with the same bore (640mm) and 640*4.5=2880mm stroke (typical value in the state-of-the-art low speed 2-stroke marine engines).

It is easy to calculate that the “surface to volume” ratio of the first is about double than the second.

Besides, the lubrication of the cross-head slippers and guides is so good that even with extremely short connecting rods (con-rod to stroke ratio around 1.15) the overall thermal efficiency of the long stroke low speed marine engines is the best among all thermal engines (and this operating with cheap, heavy fuel oil.

Your objections?

The above are for marine and power station application.

What about the use of the PatMar as the prime mover for heavy-duty trucks?

Why not a 90mm bore / 400mm stroke four-in-line (10 lit 2-stroke) with crossplane crankshaft (even firing) and full balance? If it makes its maximum torque at 600 rpm and its maximum power at 1000 rpm, what is the problem?

The loads on the pistons and on the connecting rods compare to those of a conventional 2 liter four stroke Diesel of a small car.

Objections?

Questions?

Thanks

Manolis Pattakos

Edited by manolis, 01 April 2012 - 06:11.