The pollution from a "normal" two stroke engine is not due to the oil mixed with the fuel as is so often stated, it is due to unburned fuel+oil in the exhaust.

From time to time I run out of lawnmower fuel and use the chainsaw fuel in the lawnmower. The four stroke Honda lawnmower produces no smoke at all when using this same 30:1 fuel/oil mix. Neither did my old BMW when I used the chainsaw juice in that after running out. The chainsaw produces the vile blue exhaust common to carburretted two strokes.

The exhausting of unburned fuel is the main reason the crankcase scavenged two stroke is so thirsty. Not a problem for Diesels as no fuel is injected until safely after the exhaust ports are closed and scavenging is done with clean air only. Hence the (limited) success of two stroke Diesels of various configurations.

Quote from:

“Effects of Lubrication System Parameters on Diesel Particulate Emission Characteristics”

R. B. Laurence and Victor W. Wong and Alan J. Brown

Sloan Automotive Laboratory

Massachusetts Institute of Technology. . .

Diesel particulates are commonly defined as any exhaust material, except water, that can be collected on a filter in diluted exhaust at a temperature below 53

oC, following protocols established by the US Environmental Protection Agency (EPA). Particulates consist of aggregates of small particles. Predominantly, each particle comprises a carbon core with a complex collection of hydrocarbons and inorganic compounds which have condensed or adsorbed on the surface. It is the collection of adsorbed compounds, particularly the carcinogenic polynucleic aromatic hydrocarbons (PAH), which may create the most significant health risks. Using traditional analysis, these compounds can be extracted using organic solvents such as dichloromethane, and the soluble organic fraction (SOF), i.e. the soluble organic percentage of the total particulate mass, can thus be determined. Clearly, it is desirable to reduce not only the total particulate rate, but the harmful carcinogenic compounds found in the SOF.

. . .

Percentage contribution of lubricant to the total particulate matter varies predominantly by engine condition, reaching as high as 70% of total particulates and 90% of the soluble organic fraction in the particulates under some operating conditions, viz, light to medium loads. The problem is less severe at high loads, as most of the consumed oil is oxidized due to the higher temperatures. For engines of older vintage, the oil contribution to particulates alone far exceeds the current standard for the total particulate matter for new engines. The lubricant contribution will become increasingly important as the total particulate emission level continues to be reduced in the future.

. . .

TEST MATRIX:

Three variables were used for this study.

Each test condition was run five times for repeatability.

Two production oils of differing viscosity (10W-30 & 15W-40) with the standard manufacturer's ring configuration were used for the first comparison.

Then, using the 15W-40 oil, the top ring gap was enlarged for a second comparison.

For each of these three lubricant parameter conditions, the engine was tested at three loads.

45 total tests were conducted for final analysis.

. . .

CONCLUSIONS

The results indicate that lubricant viscosity and the gap size of the top piston-ring do have a significant effect on diesel particulate emissions. Various specific conclusions can be drawn from the results and are summarized as follows:

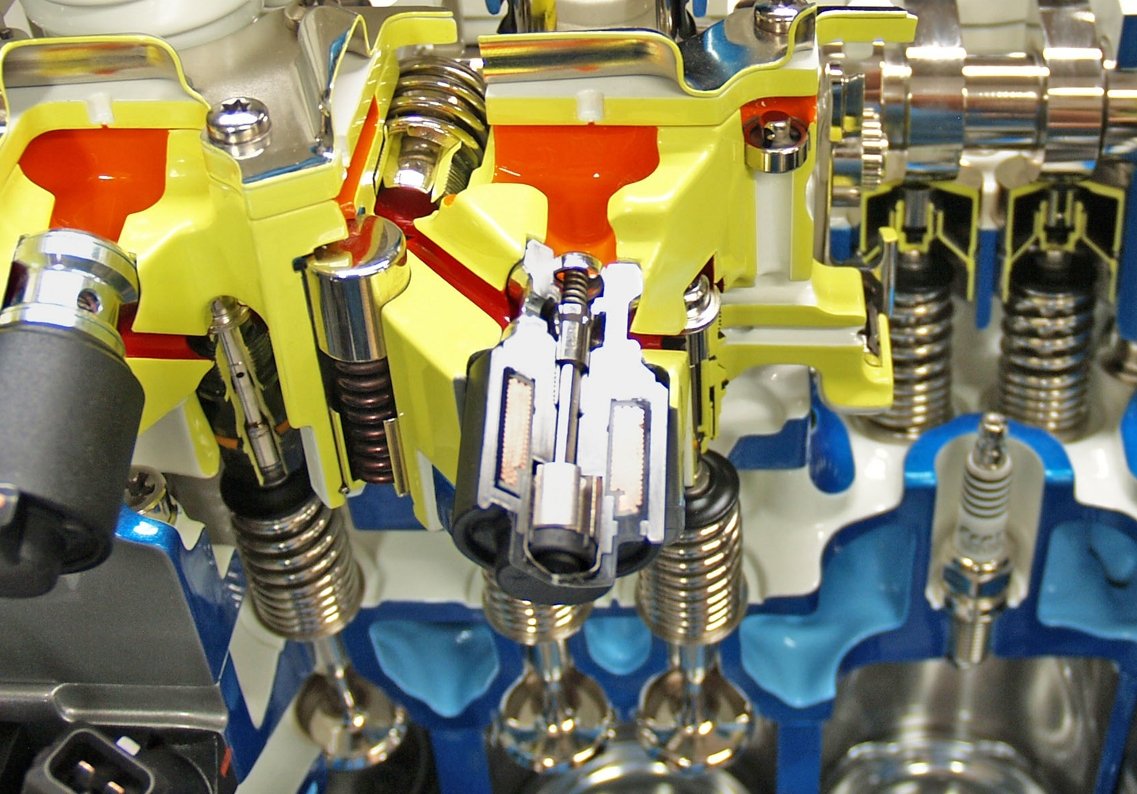

1. Total particulate emission rate increases with decreasing viscosity. This effect is due most likely due to two mechanisms. First, the decreased viscosity leaves a thicker film on the liner during and after the expansion stroke, allowing more oil to participate in the combustion event. Second, decreased viscosity allows a larger puddle of oil to accumulate and subsequently pass through the ring gap when the cylinder pressure falls below the inter-ring pressure, again allowing more oil into the combustion chamber.

2. Total particulate emission rate increases with an increased ring gap width. This result is also derived from the ring-gap reverse flow theory of oil consumption, whereby oil passes through the ring gap and is consumed when the cylinder pressure falls below the inter-ring pressure. The results of this study serve to further confirm the presence of this oil transport mechanism and the significant effect it has on oil consumption and emissions.

3. At hotter conditions, the extra oil present in the combustion chamber due to changes in a lubricant parameter is mostly partially oxidized and emitted as carbonaceous material. At cooler conditions, most of this extra oil remains in some hydrocarbon form and is eventually adsorbed on the particulate, thereby contributing to the oil derived soluble organic fraction of the particulates.

4. Changes in lubricant parameters affect not only the oil-derived emissions, but fuel-derived emissions as well. Through the process of fuel absorption and desorption, increased oil on the liner prevents additional fuel from participating in the combustion event, thereby increasing the fuel derived portion of the soluble organic fraction of the particulates.

5. Engine load has an effect on particulate emission rate and composition. At higher loads, the soluble organic fraction is reduced. The greatest total particulate rate is at low load, while the medium load condition created the lowest rate. This agrees with traditional findings.

6. Simultaneous measurements of the oil distribution in the piston ring-pack, using methods such as the laser-induced-fluorescence, and real-time oil consumption as well as particulate measurements will further elucidate the mechanisms by which lubricant contributes to the total particulate emissions and the opportunities for improvement.

You can find the complete pdf article in the Internet, or at:

http://www.pattakon....ssionDiesel.pdfIt is a little bit old (from the refferences it seems it was published in 1995).

Yet it is experimental work and comes from the "Sloan Automotive Laboratory", MIT.

It shows that the reduction of the lubricant consumption in a Diesel engine (2-stroke or 4-stroke) is vital.

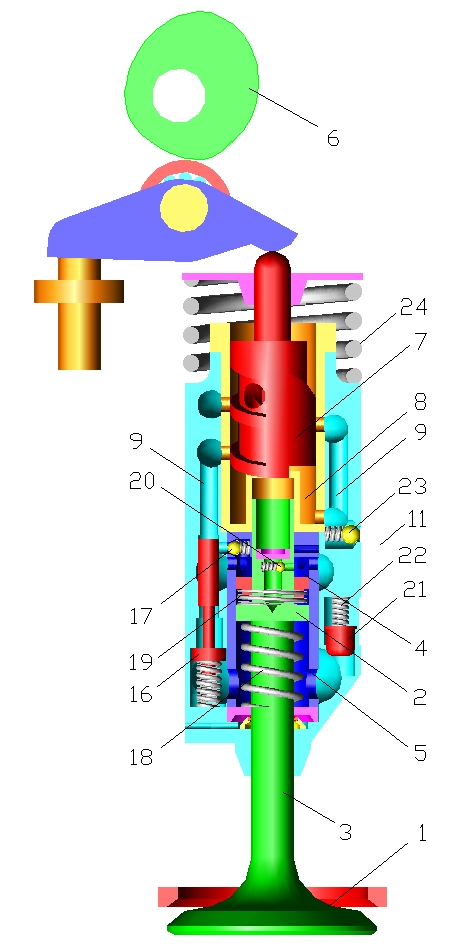

Compare the case of the OPOC engine of EcoMotors / Bill Gates (the piston thrusts heavily onto the hot cylinder wall, above the ports, and needs plenty of lubricant there, making inevitable the increased lube consumption) to the Achates "cross-head" Opposed Piston engine (they claim 0.1 gr/KWh specific lube consumption) and to the PatOP "cross-head" Opposed Piston engine (

http://www.pattakon....ttakonPatOP.htm ).

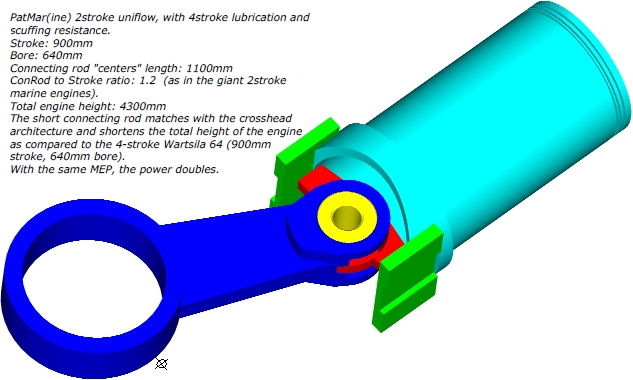

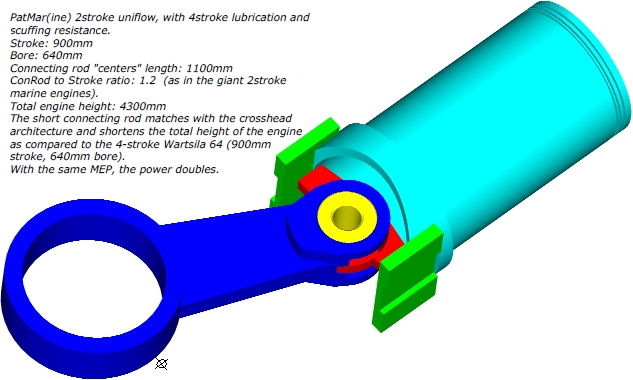

Then think of the potential of the 2-stroke PatMar architecture (

http://www.pattakon....takonPatMar.htm ) :

for low specific lube consumption (lower even than the 4-strokes).

As for the spark ignition high compression 4-stroke engines, things are not so different during combustion, even if "the four stroke produces no (visible) smoke at all when using 30:1 fuel/oil mix".

Thanks

Manolis Pattakos