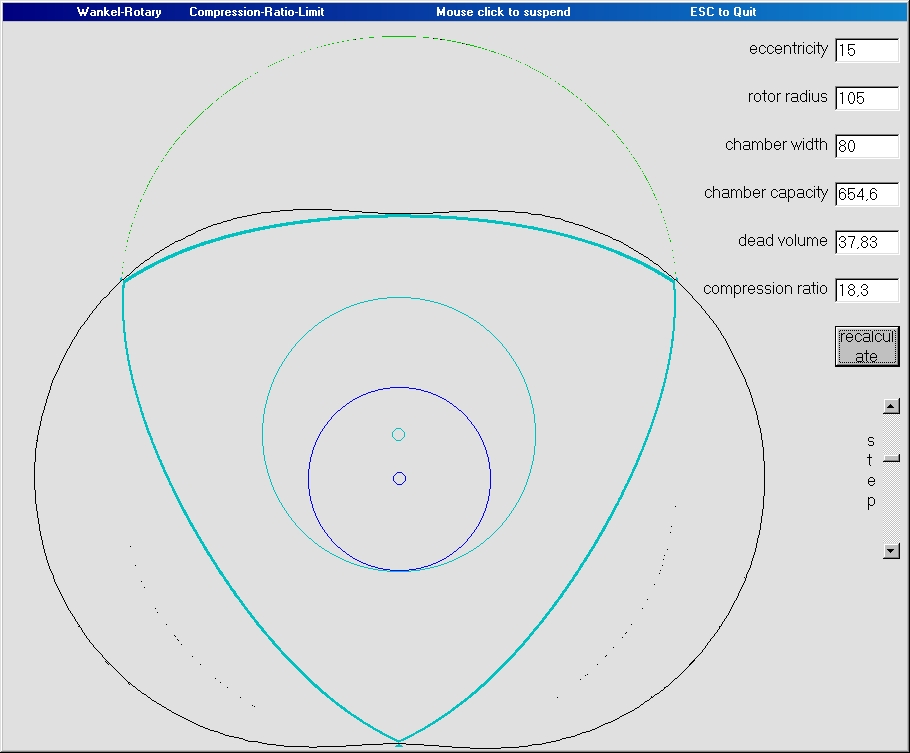

Mazda optimizes the Wankel rotary design by the selection of ,ore shallow (less-deep) rotors.

Quote from Mazda's patent:

The relationship of the dimension parameter L/b and the combustion stability can be explained as follows.

To increase the combustion speed, the rotary piston engine has two spark plugs, one on the trailing side and the other on the leading side, with a predetermined distance therebetween in the rotor rotation directions (in other words, the circumferential directions of the rotor; it should be noted that, in this specification, the "rotor rotation directions" include the direction in which the rotor rotates and the direction opposite to the rotation of the rotor) such that the spark plugs meet a working chamber in the compression interval through the expansion interval. The flames generated by ignition of the trailing side plug and the leading side plug (T-side flame and L-side flame) propagate in both rotor rotation directions and rotor breadth directions. Due to the structure of the rotary piston engine, the speed of propagation of the flames in the rotor rotation directions is relatively high while the speed of propagation of the flames in the rotor breadth directions is relatively low as compared with the propagation speed in the rotor rotation directions.

The T-side flame propagating toward the leading side seen in the direction of the revolution of the rotor and the L-side flame propagating toward the trailing side collide with each other near the midpoint between the two flames. After the collision, combustion of the T-side flame and the L-side flame both attenuate so that the flame propagation speed decreases in both rotor rotation directions and rotor breadth directions.

Now, consider decreasing the dimension parameter L/b on the premise that the rotary piston engine takes the above-described combustion form. Decreasing the dimension parameter L/b while the displacement is maintained constant corresponds to relatively decreasing the length L of one side of the rotor while relatively increasing the breadth b of the rotor. Namely, the rotor has smaller triangular faces but a greater breadth. Decreasing the length L leads to a shorter distance between the trailing side spark plug and the leading side spark plug so that the time between the generation of the T-side and L-side flames and the collision of the flames becomes shorter. Due to the increase in breadth b and the shortened time before the collision of the flames, the collision of the flames occurs before the T-side flame and L-side flame propagating in the rotor breadth directions reach the side housing. After the collision of the both flames, the flame propagation speed decreases, and as a result, the flames do not expand so much in the rotor breadth directions.

On the contrary, consider increasing the dimension parameter L/b. Increasing the dimension parameter L/b while the displacement is maintained constant corresponds to relatively increasing the length L of one side of the rotor while relatively decreasing the breadth b of the rotor. Namely, the rotor has larger triangular faces but a smaller breadth. Increasing the length L leads to a greater distance between the trailing side spark plug and the leading side spark plug so that the time before the collision of the flames becomes longer.

Due to the longer time before the collision of the flames and the decreased breadth b, the T-side flame and L-side flame propagating in the rotor breadth directions reach the side housing before the collision of the flames occurs. After the flames reach the side housing, the pressure in the vicinity of the side housing increases so that the flames are redirected to propagate in the rotor rotation directions. As a result, the propagation of the flames in the rotor rotation directions is enhanced. Thereafter, the T-side flame and L-side flame propagating in the rotor rotation directions collide with each other.

As the combustion stability is improved by increasing the dimension parameter L/b, improvement in the combustion pattern in the working chamber is also expected.

According to one aspect of the present invention, a rotary piston engine includes: a rotor which orbits around an output shaft axis, rotates around an eccentric shaft that is aligned in parallel to and offset from the output shaft axis, and has a generally triangular face as seen in the axial direction; a pair of side housings which are arranged at both axial sides of the rotor to be in contact with side seals of the rotor; a rotor housing which accommodates the rotor therein such that an inner surface of the rotor housing is in contact with apex seals of the rotor, the rotor, the pair of side housings and the rotor housing defining three working chambers; an intake port formed in at least one of the side housings to be capable of communicating to one of the working chambers to induct air into the working chamber; and an exhaust port formed in at least one of the side housings to be capable of communicating to one of the working chambers to exhaust combusted exhaust gas from the working chamber.

…

As described above, increasing the dimension parameter L/b while the displacement is maintained constant corresponds to increasing the length L while decreasing the breadth b, hence corresponding to a more elongated shape of the working chamber. Therefore, the surface/volume ratio (S/V ratio) of the working chamber over the compression interval and the combustion interval decreases. This leads to an improvement in thermal efficiency so that the fuel efficiency is further improved.

However, the Surface to Volume ratio (S/V) of the working chamber increases when the breadth b of the rotor decreases.

And this is pure / simple Geometry / Mathematics.

On the other hand, Mazda deals with the Wankel rotary for some fifty years.

Am I wrong?

Thanks

Manolis Pattakos