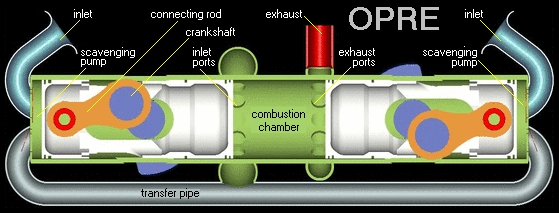

Valves on the cylinder head (like poppet valves, reed valves etc) control the working medium flow.

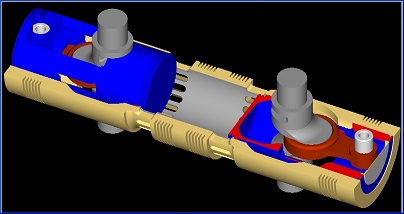

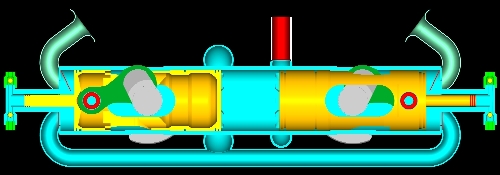

In the Pulling Rod Engine below (combustion chamber at bottom-left, scavenging pump at right), a blade valve (or blade) is secured to the connecting rod:

The blade moves inside the chamber while the connecting rod moves inside the crankcase.

The chamber and the crankcase are sealed from each other.

Following the connecting rod motion, the blade covers and uncovers (in synchronization to the piston motion) inlet and exhaust ports properly formed onto the cylinder head.

The geometry / shape of the blade and of the ports define the timing of the opening / closing of the inlet and exhaust ports. Larger ports can increase the "overlap" and the flow capacity in high revving applications.

Lightweight materials, like Carbon-fiber, Kevlar etc, seem more than adequate for the blade valve that sees only low pressures and temperatures.

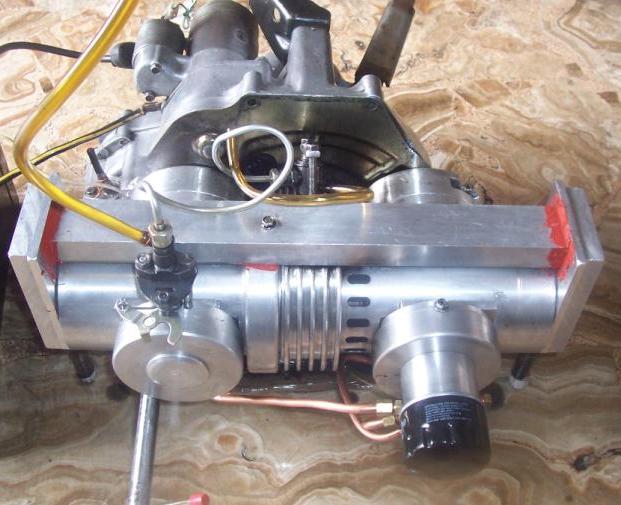

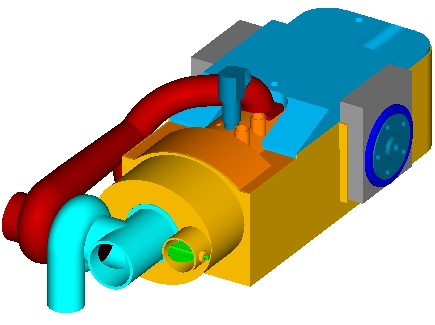

The application of the blade valve on the PatOP engine could be like:

The controllable windows exe animation is at http://www.pattakon....e/PatBlade1.exe

The controllable windows exe animation is at http://www.pattakon....e/PatBlade2.exe

The scavenging-pump cylinder-head adds "height" to the engine, the long-stoke of the exhaust piston subtracts "height" from the engine.

The combustion pistons are both crosshead-pistons, i.e. they can operate without touching the combustion-cylinder-liner (lube-oil consumption / scuffing resistance / emissions).

The scavenging-pump cylinder-head operates at low temperatures and pressures, allowing cheap and easy to mold materials.

Among the advantages of the blade valve is the high flow capacity, the small dead volume, the reliability, the progressive opening and closing of the ports, the lower noise and the simplicity (there are only three moving parts: the crankshaft of the engine, the piston of the engine and the connecting-rod/blade of the engine).

Objections?

Comments?

Thanks

Manolis Pattakos