The plot:

shows, at left, a typical symmetric timing of a two-stroke.

With symmetric timing, the transfer port opens after the exhaust port and closes before the exhaust port.

Time is required to pass from the opening of the exhaust port till the opening of the transfer port (translated into crankshaft degrees) in order the pressure inside the combustion chamber to fall substantially.

The same time passes from the closing of the transfer port till the closing of the exhaust port (case of zero offset), giving the chance to a good part of the fresh air or mixture to escape from the open exhaust port under the action of the upwardly moving piston, reducing the torque and increasing the emissions.

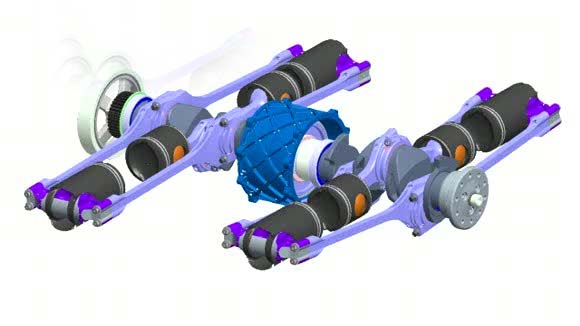

At http://www.pattakon....ttakonPatAT.htm it is presented the PatAT:

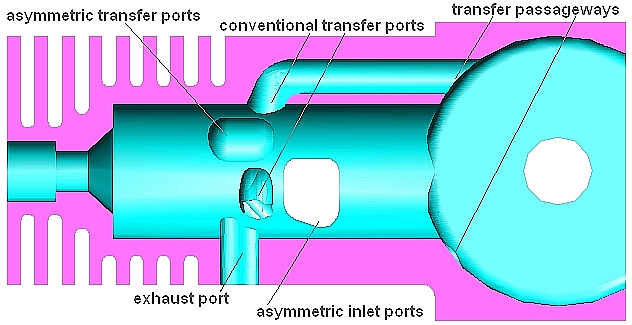

In the PatAT the source of pressurized air of mixture (the crankcase in most cases) communicates with the combustion chamber through transfer ports disposed in series with respective piston ports.

The transfer ports are controlled by the piston.

The piston ports are controlled by the connecting rod.

The source of pressurized air or mixture can, additionally, communicate with the combustion chamber through conventional transfer ports (that open by the piston after the exhaust port).

As the piston moves "downwards", it initially opens the transfer ports; but with the respective piston ports closed by the connecting rod, the combustion chamber cannot communicate with the crankcase (or, in general, with the scavenge pump).

The piston continues its downwards motion and opens the exhaust port; the pressure inside the combustion chamber drops quickly; the crankcase continues to remain sealed from the combustion chamber.

Later the connecting rod opens the piston ports (and the piston opens the conventional transfer ports, if any). The transfer takes place.

As the piston moves upwards, it initially closes the conventional transfer ports (if any).

Later the piston closes the exhaust port.

The crankcase is still communicating with the combustion chamber: after the closing of the exhaust port, air or mixture continues to enter (through the "connecting rod controllable" piston ports and their respective transfer ports) into the combustion chamber untill the transfer ports to close by the piston.

A high revving model / RC engine with ringless piston and the PatAT would be interesting.

Also the comparison of the emissions and of the torque of a conventional two stroke and of its modified to PatAT version.

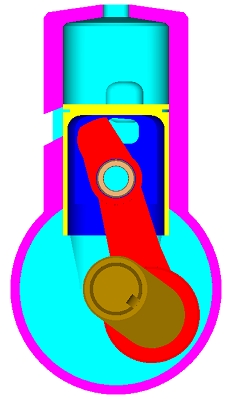

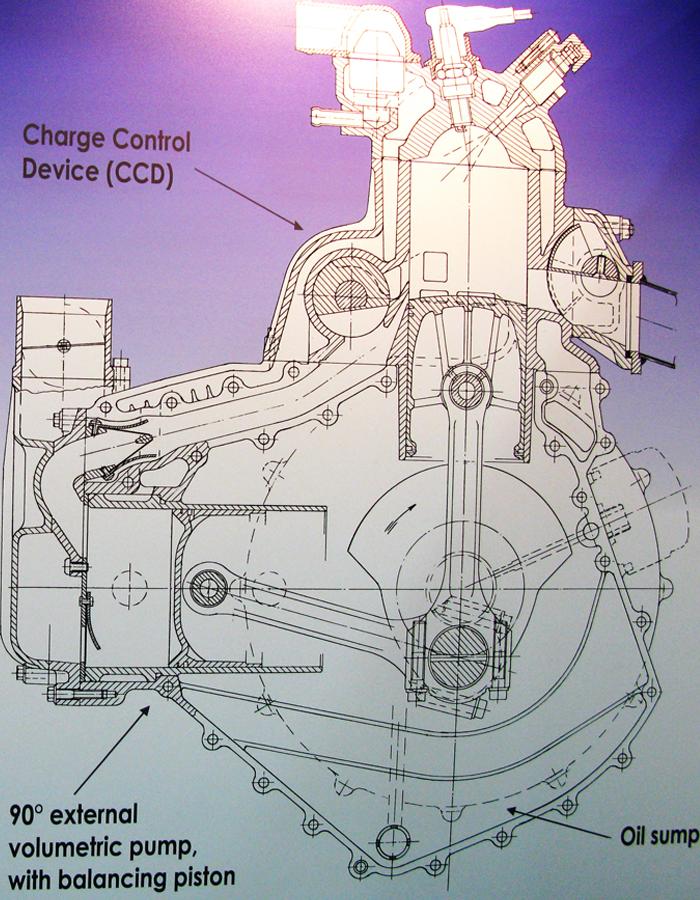

With external scavenging pump (say a turbocharger), the PatAT can combine the four-stroke lubrication with the asymmetric timing (say in Diesels, in Direct Injection spark ignition etc), like:

or like:

The separating plate at the middle of the piston seals the space underneath the piston crown from the crankcase.

Through openings in the cylinder and in the piston, the pressurized air or mixture enters into the combustion chamber either directly or indirectly (it initially goes into the space underneath the piston crown and then, through a piston port controlled by the connecting rod and then through a transfer port controlled by the piston, it gets into the combustion chamber).

If the "stroke" of the oil-scraper-ring and of the lowest compression spring overlap (as in the animations above) and if the area of the cylinder liner wherein the oil-scraper-ring slides is rid-of-ports, the lubracation and the scuffing resistance get quite similar to those of the four-strokes.

Thoughts?

Objections?

Thanks

Manolis Pattakos