Hi andygo,

you wont be able to achieve what you would like to do, by just preloading a softer (linear) spring - other have already explained the reasons.

If you use a progressive spring, on a droop limited damper/suspension then adding preload would change the effective springrate around the point of operation, but this may becomes slightly confusing in practice, and would require that you could get a "perfect" progressive spring made for the application at hand ( a spring with the desired spring rate transition) --> this may be not possible or if, could be expensive (custom made spring in low quantities)

What you could consider as a practical, workable and economical solution - IMHO - is using the softer spring ( the 250 lbs you mentioned, if this is a good setup for the wet), and then go and fit a "spring rubber" or whatever these things are called in your part of the world.

The underlying idea is, that you reduce the number of active coils [N] in your given spring and thereby increasing the springrate. Following from this relation.

So in the dry, you would run with them, and in case it starts to rain, you just pull them out on the grid or before going to the grid, and adjust the ride height back to where you want it by xx turns/flats (or whatever you use) at your push/pull rod.

Depending on the type of open wheeler you run, and the series, you could even attempt to to this (pull them out) during a pitstop, while changing onto your wet tyres.

( if this is feasable or not, you will know for yourself).

You will need to experiment a little bit around, to find the "correct" spring rubber ( they come in different shore hardness) and will need to see, how many coils you need to "block out" with them, to get to the higher rate you want. You can use the above given formula as an indication, as you know the springrate of your spring and can measure the ID/OD and count the number of coils.

It's a quite cheap way to "tune" your spring stiffness with only one given spring, and in small increments which are otherwise maybe not covered by "off the shelve" springs.

For most applications, this should work out o.k., you have to be a bit mindful about the maximum permissable stress levels in your spring(steel).

If you happen to run some "light weight" race springs (with steep pitch and a low number of coils --> less material --> less weight), you may end up breaking a spring, when trying to reduce the number of active coils, because these springs are allready designed at the material limit.

But for most "normal" off the shelve racing springs, this shouldn't be too much of an issue.

********

There are other options, using a in series combination of two springs ( the combined springrate if both springs are "active" will be lower then the lowest single spring rate) and then "block" one to get to the higher rate.

With this "technique" you could have 3 different spring rates from just two springs.

a.) combined springrate --> lowest = 1/ (1/springrate a + 1/springrate b) -->[Example combine a 900lbs and a 300 lbs spring = 1/ (1/900 + 1/300) = 225 lbs]

b.) use only spring rate a (block out spring b) = 900 lbs

c.) use only spring rate b (block out spring a) = 300 lbs

Therefore, you would run the second spring blocked out in the dry --> only running on the "dry" spring, and when it starts to rain, you would remove the "blocking" from the second spring and run on the compound spring rate.

This "version" requires some "space" (to fit the second spring), and it adds some weight and extra costs (for the second spring).

In the range you want to vary, the second spring would be quite stiff ( 1500 lbs if you want to go from 300 to 250), but would only require very little travel, so you maybe want to look a a bellville (spring)stack instaed of a coil spring.

Anyway, I think you get the idea.

IMHO the "spring rubber" in combination with the "rain setup spring" to bring the springrate up to "dry setup spec" is the easiest, lighest and probably most economical (cheapest) solution, for the problem at hand.

But you will know better if this works for you or not.

May need to spend a afternoon on a springtester with a "handfull" of springrubbers, to find the combination which works for you.

How many coils to block, with which type of "spring rubber".etc.,

But afterwards it's a quite straight forward process, pull out the springrubber & adjust the RH at the push/pull rod --> done.

There are/where some applications in the past, which made use of this concept (reducing the number of "active coils" on a given spring) to achieve a range of springrates from a single given spring.

Porsche used to have this on their older spec RS models and IIRC ( and I may don't) I think Radical/Intrax uses ( used to use) a similar concept on their club racing cars.

It requires a special "open end" spring and a specific spring seat design [see below].

If designed correctly, the ride height doesn't change when adjusting the spring seat to increase the stiffness.

Most people have thrown the factory setup out of their Porsche's and run different linear springs instead, because they couldn't get their "head around" the concept.

It looks something like this. ( here the rate is adjustable between 150-190 N/mm)

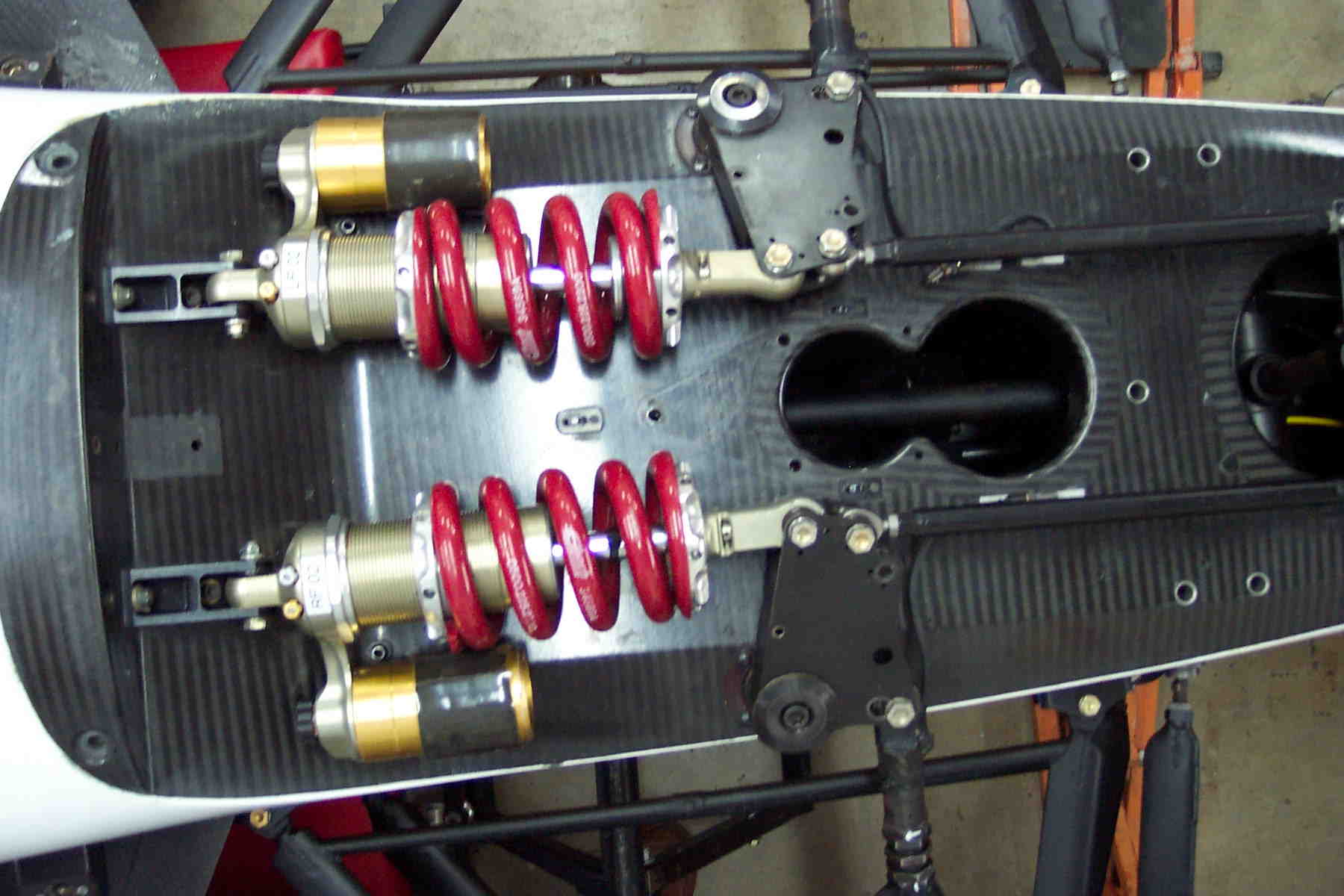

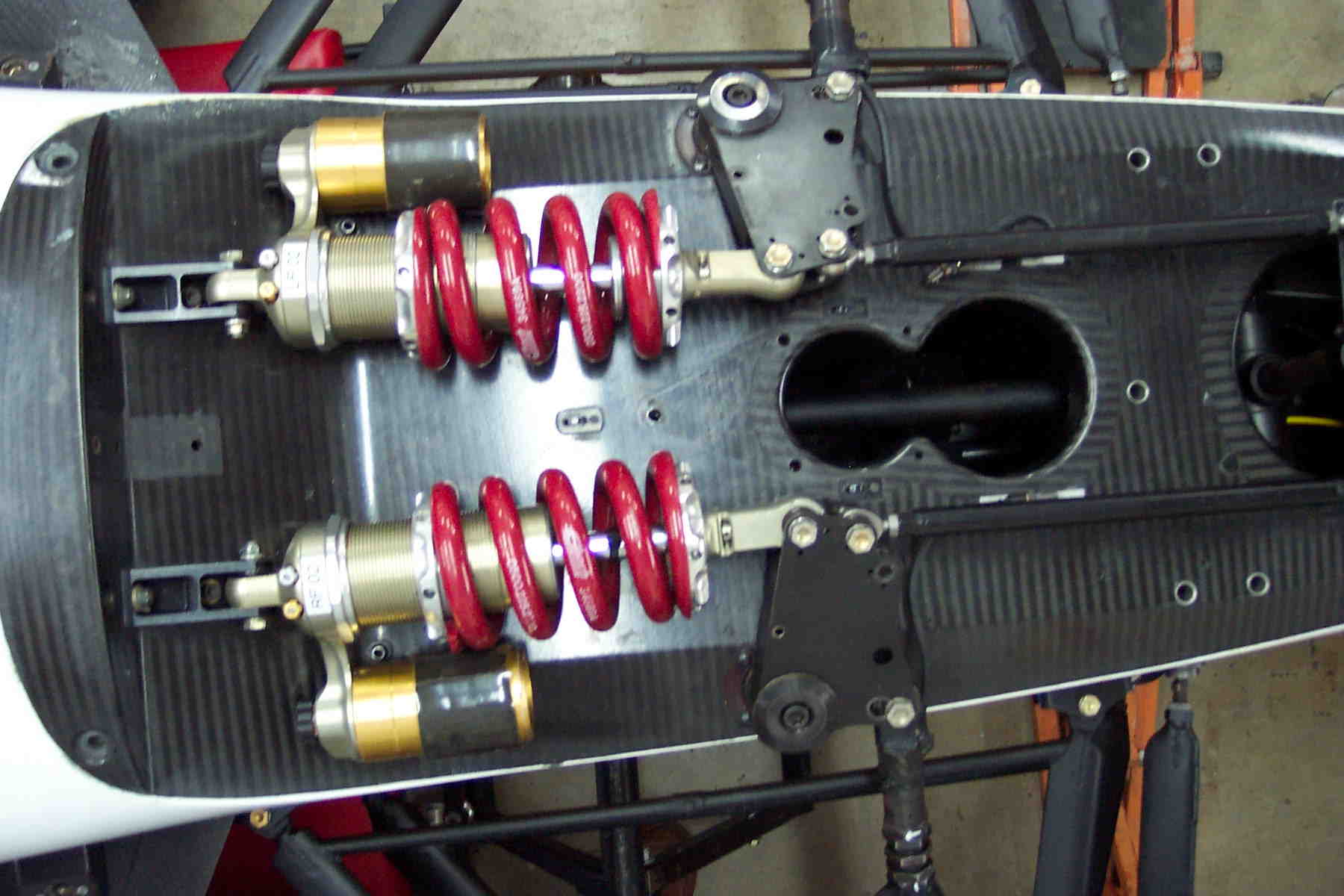

Alternatively, seeing that this seems to be a car which uses a pushrod/rocker layout you could consider changing the motion ratio of the suspension.

You will have to check if your current rocker has provision to use different positions (holes) to connect either the pushrod &/or the damper/spring unit or both.

If not, you could consider if producing a new/different rocker or modifying your current one, if there is enough room/material is a option for you.

see here as an example, the two options to connect the pushrod onto the rocker.

good luck

![]()