The advantages of the tooth belts for the transmission of power (as in the final transmission of motorcycles, for instance) and for the synchronization of shafts (like: crankshaft to camshaft) are well known: efficient, reliable, lightweight, simple, cheap, quiet, smooth, lubricant free and maintenance free.

In the typical case, a belt having teeth at one side engages a pair of pulleys (or sprockets).

A limitation of this transmission: the two sprockets (and the shafts wherein they are secured) rotate necessarily at the same direction.

In several applications, however, the two shafts must rotate at opposite direction. For instance: in order the two crankshafts (disposed at a distance from each other) of an opposed piston engine (click here) to counter-rotate in synchronization, a tooth belt would be preferable than a series of gear wheels (or than four bevel gears and a shaft); but the "same direction" limitation is not allowing the use of a tooth belt.

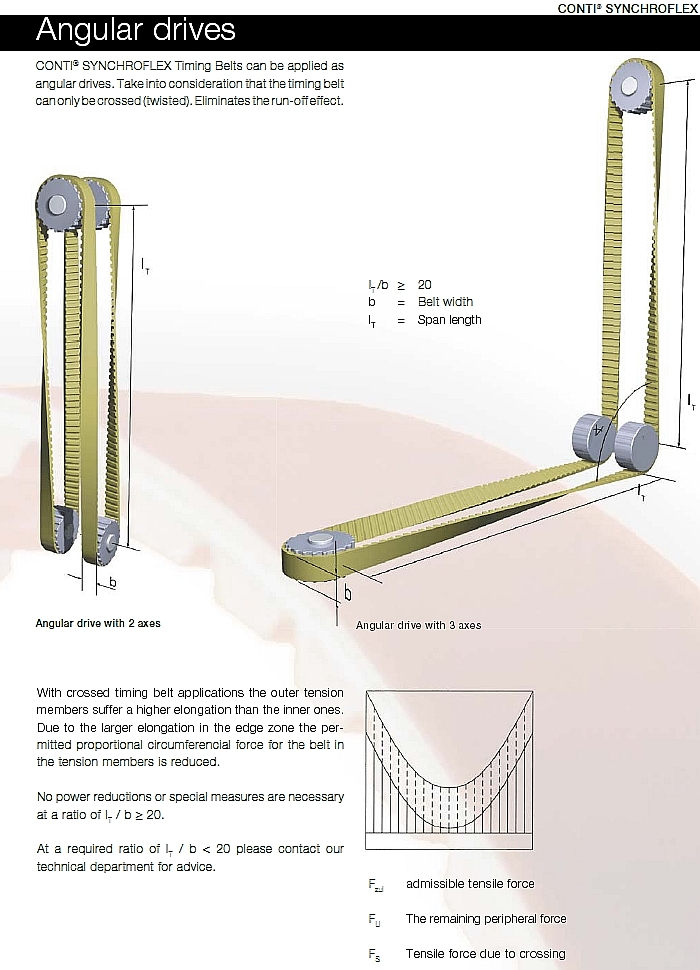

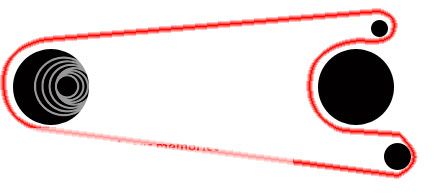

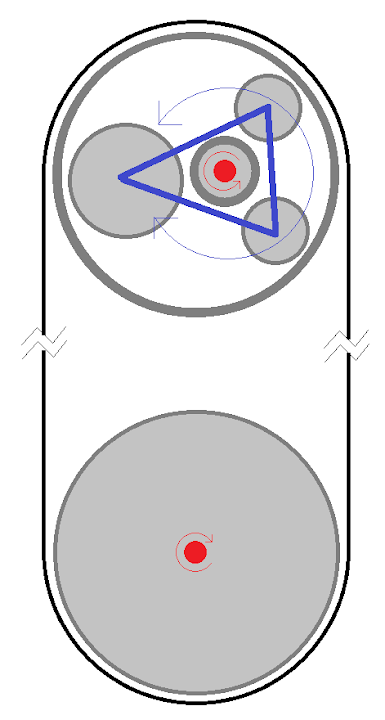

In the following image:

At (a) a conventional tooth belt is engaging a pair of tooth belt sprockets at 1:1 transmission ratio. The two sprockets rotate at the same direction.

At (b) the conventional tooth belt of the (a) arrangement is utilised in a different way: the two sprockets rotate at opposite direction with the same 1:1 transmission ratio. The distance of the two sprockets is smaller. The tooth belt forms a big "X" between the two sprockets, with the teeth, at the center of the "X", facing each other.

In order to avoid the touching / wear / friction of the teeth, the two "crossing" parts of the belt (at the center of the "X") must be kept at a safety distance by spacers, rollers, tensioners etc.

At © an unconventional, as explained in the following, tooth belt interconnects the two sprockets; the sprockets rotate at opposite direction with the same 1:1 transmission ratio.

In comparison to the (b) arrangement, at the center of the "X" of the © arrangement the backsides of the tooth belt face each other, leaving (and protecting this way) the teeth at the other "external" sides.

Even if the backsides of the tooth belt are left free to touch each other at the middle of the "X", the system works reliably:

besides keeping the teethed sides away from each other,

it is also the smaller height, measureded from the "belt pitch line", of the backside of the tooth belt (as compared to the height of the front side with the teeth), allowing a wider angle of the belt at the center of the "X".

If necessary, the surface of the backside of the tooth belt can be covered / coated with a Nylon, or other antifriction / wear-resisting, "film".

If desired, a slim spacer (made of Teflon, for instance), or rollers etc, can keep, at the center of the "X", the backsides of the tooth belt from touching each other.

Starting with a conventional tooth belt:

the following images show the steps for "making" (actually for explaining the structure of) an unconventional tooth belt like the one shown in the © arrangement.

The conventional tooth belt is properly cut (the "arrow" at the one end of the band shows how this end is to be twisted):

Keeping the one end immovable, the other end of the band is twisted for two complete turns (720 degrees):

The two ends of the twisted band are rejoined forming an unconventional / twisted tooth belt:

like that used in the © arrangement.

Unlike the Mobius belt / strip wherein there is not front-side and back-side, here the belt has a back-side rid of teeth and a front-side wherein the teeth are mounted.

Applications:

For the transmission of power between, and for the synchronization of, shafts rotating at opposite direction.

For instance, for the synchronization of the two crankshafts of the PatATi Portable Flyer at http://www.pattakon....pattakonFly.htm

For a tooth belt manufacturer the cost for making either a conventional or this unconventional toothed belt is the same.

Thoughts?

Objections?

Thanks

Manolis Pattakos