Hello Dav.

You write:

“I hate to say each time you answer It just creates other questions for me. “

Do not stop making questions.

You also write:

“1. Is this because the benefits only apply to a high performance engine as running a higher compression would only shorter the life of a conventional engine?

2. Is the increased complexity of the Rotary valve simple a cost factor?”

Yes and no.

If the F1 rules were not changed to ban the rotary valves,

and if the Bishop rotary valve F1 engines were in practice (in the race) as good as in the lab,

the guys in Bishop could gather money, recognition and momentum to try to put their ideas in normal engines.

The change of the F1 rules killed instantly the Bishop project / company.

However, for normal applications the exhaust emissions of a mass production engine must comply with the regulations (like, say, Euro 6).

The specific lube consumption (grams of lubricant per kWh of energy produced) in a Bishop rotary valve engine cannot help being several times higher than in normal engines.

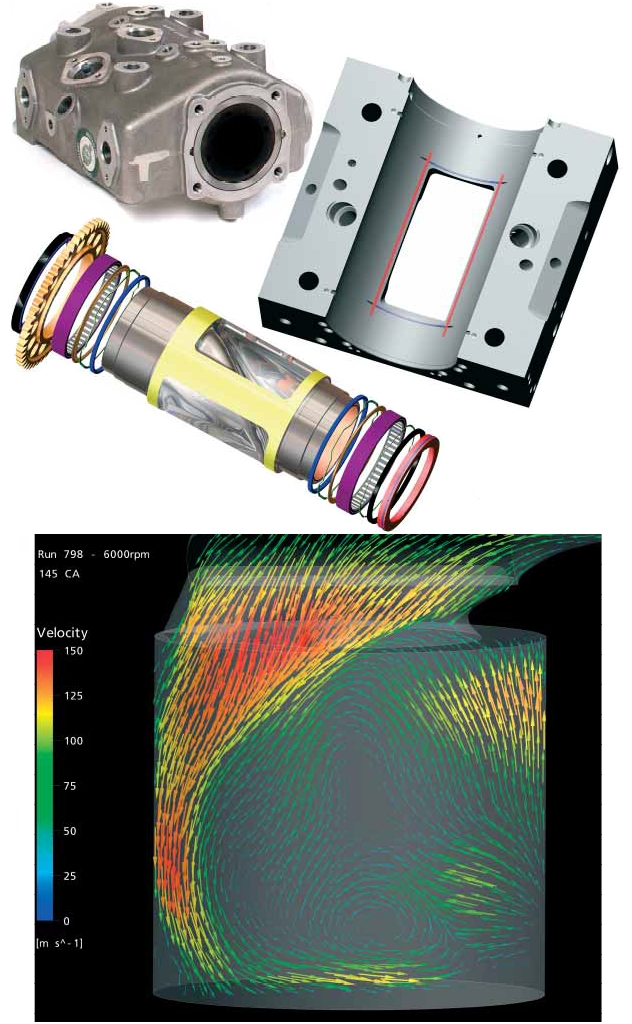

The BRV (Bishop Rotary Valve) needs lubricant for its seals, and it is difficult this lubricant to be collected and recycled because the seals pass over ports (as in the two strokes).

With plenty of lubricant into the combustion chamber the emissions worsen ( read at

http://www.pattakon....ssionDiesel.pdf an article of MIT).

Coates uses dry seals in his Spherical Rotary Valves (CSRV) and “claims” he solved the problem.

However his patents already expired without achieving to put his spherical rotary valves in mass production, despite the millions invested, and lost, by his investors.

A simple rotary valve like the PatRoVa makes the cost of the cylinder head substantially lower. Reasonably, in mass production a PatRoVa cylinder head (there is only one moving part inside) of similar “capacity” with a Panigale Desmodromic cylinder head will have several times lower cost.

Thanks

Manolis Pattakos