Posted 13 August 2017 - 04:36

Advertisement

Posted 13 August 2017 - 23:39

A good idea. Is this better than simply moving the sheaves apart/together? Or are you just trying to defeat the centrifugal shift mechanism present in simple CVTs rather than proposing a new way of shifting CVT's in general?

Posted 14 August 2017 - 05:05

Hello Gruntguru.

The idea is to turn the now uncontrollable CVT’s of the scooters, to controllable CVT’s.

Say, as controllable as the unique SECVT of the Suzuki Burgman 650 (and of the ApriliaMan 850) but without its drawbacks (the worst of which: the US2,000$, or so, it adds to the price of the scooter).

The typical dilemma of a scooter owner is which is the best variator (or roller weights) for him.

He likes the faster accelerations the sport aftermarket variators offer, but he dislikes the higher fuel consumption, the reliability issues and the noisy / exhausting operation at long trips on the highway.

He likes the better mileage and the quieter / comfortable / more reliable operation in case the rollers in his variator are replaced by heavier ones, but he hates the slower accelerations and the unsafe feeling at overtakes or when riding at uphill roads with opposite wind.

In the scooter forums it is quite common to read something like:

The available weights (or rollers) for the variator are from 14gr to 20gr.

However with the 20gr rollers (which give the best mileage and reliability) the scooter keeps so long transmission ratios that . . .

However with the 14gr rollers (which give the top accelerations) the noise is tiring, the consumption too high, the wear of the “engine / V-belt” faster. . .

With the PatCVT, the rider of the scooter can go as if not having the PatCVT. He/she just leaves the lever, whereon the sprocket is rotatably mounted, free.

When the rider likes quieter operation and better mileage (say in a long trip on the highway), a lever is pulled (or a button is pressed) and a control spring pushes the lever/sprocket forwards. The heavier the preloading of the “control spring”, the longer the transmission ratios selected by the CVT.

When the rider likes faster accelerations, sport driving, top performance, a lever is pulled (or a button is pressed) and a control spring pushes the lever/sprocket backwards. The heavier the preloading of the control spring, the shorter the transmission ratios selected by the CVT.

And when the rider wants full control over the transmission ratio, the lever is displaced by rider's foot (“manually”?) as required, and the CVT shifts to the desirable transmission ratio.

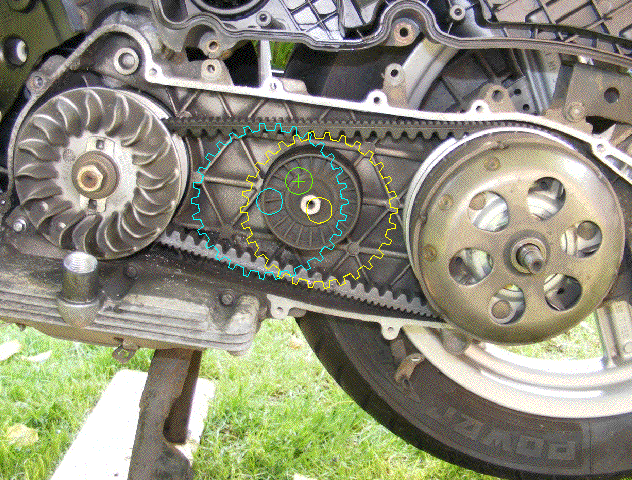

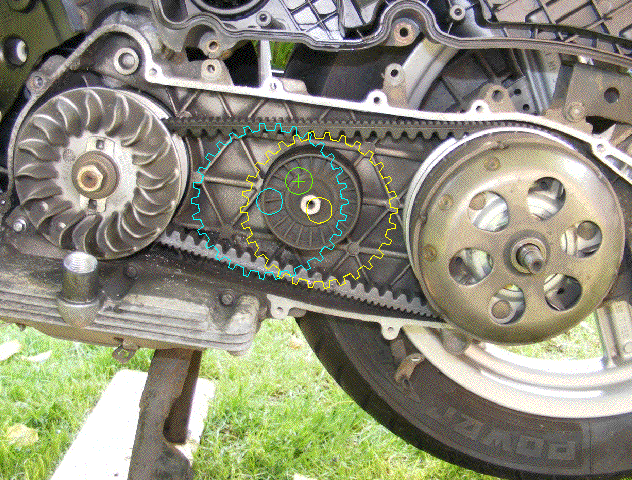

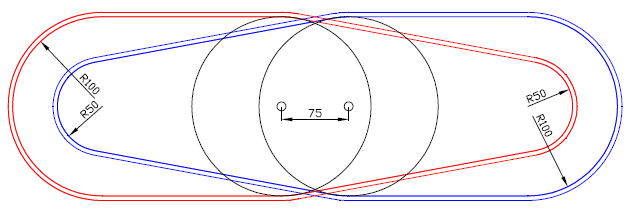

The above drawing shows the required displacement of the sprocket (black circles) from the minimum to the maximum transmission ratio in a typical CVT having a ratio range from 1:2 to 2:1.

The displacement of the center of the sprocket is about 75% of the maximum radius at which the V-belt rides on the conical pulleys.

The changes required for the modification to PatCVT are easy and cheap.

In mass production the added cost is a couple of dozens of dollars.

The way the several millions of scooters operate today is a significant waste of resources.

Just imagine how many thousands of tons of less CO2 would be emitted to the atmosphere each day from the scooters if their “uncontrollable” CVT’s were modified to “controllable” ones.

The PatCVT is a solution of the problem:

The PatBox is another solution of the same problem:

Thanks

Manolis Pattakos

Posted 14 August 2017 - 11:37

You could run into issues with slip on the "puller" So in a way the PatBox is better even tho it is more complicated.

But you can improve potential slip issues by having rollers on the outside of the "puller" Making it harder for the teeth to slip over.

perhaps it would be sufficient with the rollers mounted on a three hole arm where they are freely rotating around the "puller" arms center.

Edited by MatsNorway, 14 August 2017 - 11:40.

Posted 14 August 2017 - 14:21

Hello Mats Norway.

You write:

"But you can improve potential slip issues by having rollers on the outside of the "puller" Making it harder for the teeth to slip over."

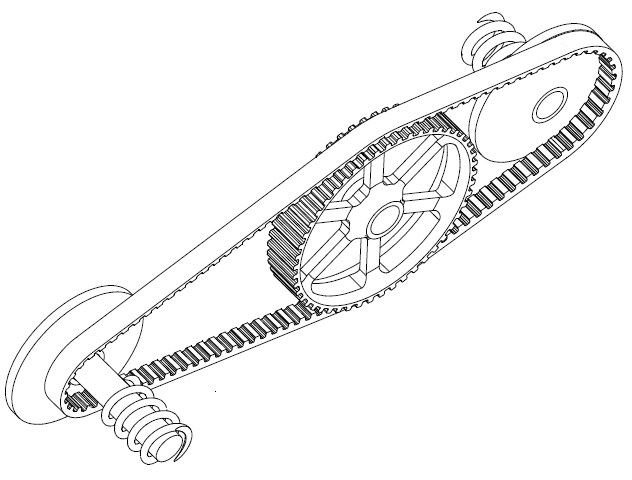

Or, by just using bigger / deeper teeth:

By the way, the sprocket, among others, halves the free span of the V-belt, reducing a lot the vibrations / oscillations of the V-belt and the posibility for teeth jumping.

Thanks

Manolis Pattakos