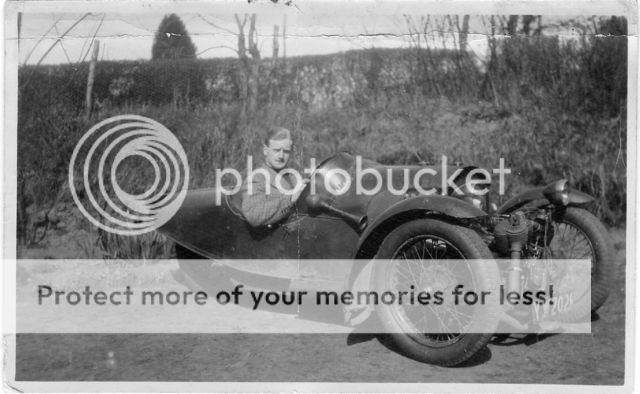

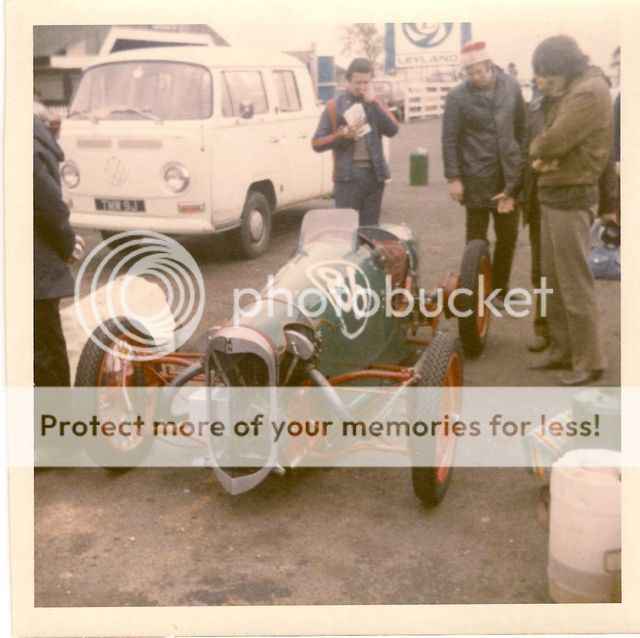

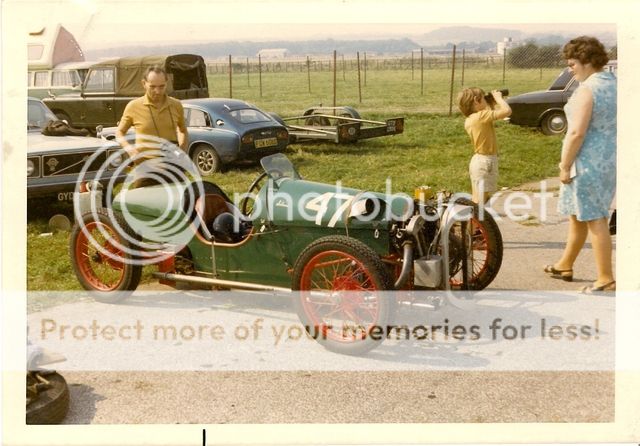

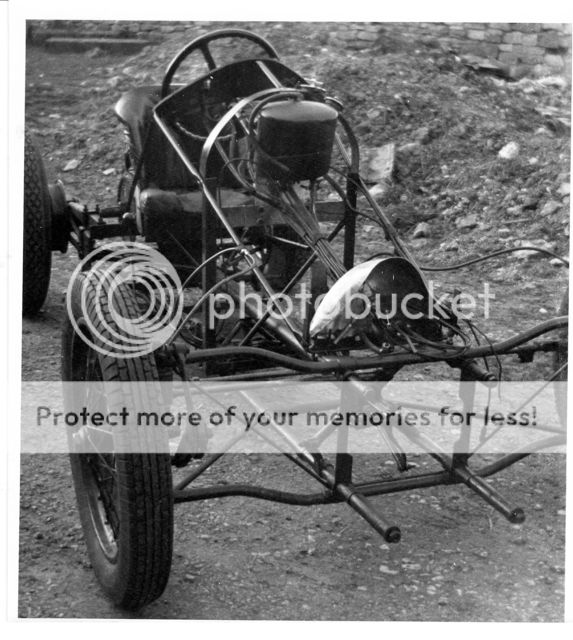

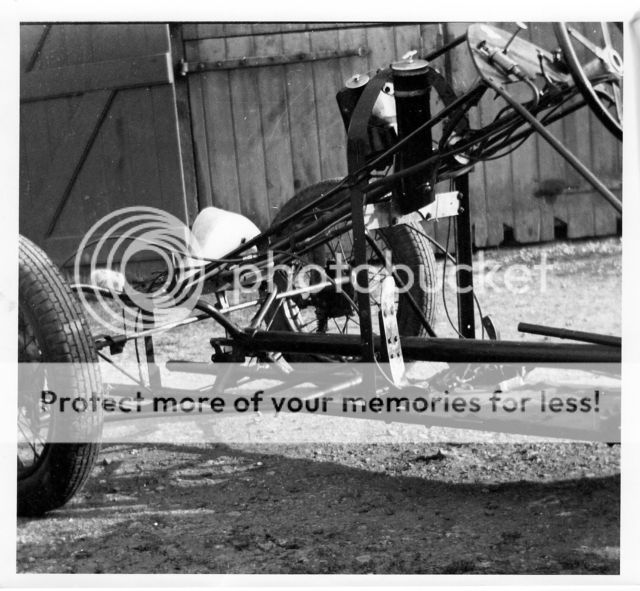

"I was patching up Salome for the next Meeting on the Crystal Palace Dirt Track, but while trotting across the road I twisted my ankle badly, and an X-ray disclosed a broken bone in my foot. That little fracture altered my career; Salome languished in the Mews, and I returned to Cambridge. However, my foot got no better, and I couldn't get to lectures. Under the circumstances I didn't seem very likely to pass exams. Time and money were getting short, so J.P.Smith (a John's man who raced a 250 c.c. Motorcyle special) and I decided to go down and join the de Havilland Technical School. For a long time Salome languished in the open car park. Then she was towed to Hatfield, and complete reconstruction started. The body was removed, and the chassis completely stripped. The bevel box had come adrift, and the selector rod and tube bent through a right angle. The countershaft was badly twisted and blue. So much for an errant chain! With the aid of a large soldering iron and many Bunsen burners I fixed the bevel box and put in a new selector rod and tube. I decided that the rear part of the chassis required stiffening. The angle irons which are bolted across the bevel box and carry the springs, etc. were bent. Heavier ones were substituted and a web of 20 s.w.g. Steel welded between them to stop “weaving” and distortion of the bevel box. Two 8 s.w.g. Steel plates were bent and bolted to the ends of the L irons and spring mountings. Extensions were sweated into the ends of the tube that runs across through the bottom of the bevel box. The lower ends of the 8 s.w.g. Plates were bolted to the ends of these extensions. A long ½” diameter rod passes through these plates, and through the short tubes on which the Morgan rear fork used to pivot; on this rod the GN type rear axle radius arms now pivot. To produce further stiffness two tubes run from just inside the pivot points forwards and inwards to meet on the central “backbone” tube where they are bolted to a massive clamp. The rear springs (GN quarter elliptic) were reset dead flat and bound with blind cord, doped and fabric doped on to that. No rear shockers have been found necessary! A new track rod and drag link were made of 2S2 Nickel Chrome Steel. The steering and controls were centralised and a bucket seat (out of an Avro) was fixed to the bevel box. A kind of superstructure was made to carry petrol and oil tanks, and the steering column tube with its epicyclic reduction box. The brakes are (Bowden) cable operated, and the actuating mechanism is rather unique; in fact, J.P.Smith and I did go into the question of patenting it. Roughly speaking, a pedal, on being depressed, spreads the arms of a toggle. To the ends of these arms are attached the stops for the outer part of the Bowden cables. One continuous inner cable goes from one front brake to the other. There is a gap in the middle of the outer cable, and the toggle mechanism spreads this gap, thus increasing the effective length of the whole outer cable. The advantage of the toggle is its progressive leverage; this rapidly gathers up all slack and lost movement in the brake mechanism, and yet gives great leverage when fully applied. In fact, the more the brakes wear, the harder they come on! If we had a differential in the rear axle we should operate the rear brakes in exactly the same way. It will be realised that the continuity of the inner cable ensures completely compensated braking. With regard to the rear brakes, we use one drum for the hand brake, and the other is operated by the same toggle mechanism. In this case the outer cable is stopped at the end of one toggle arm, and the inner cable at the other.

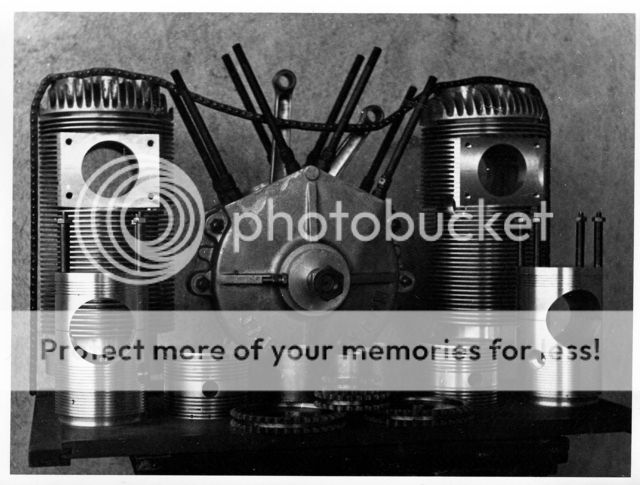

The engine was not touched, except for the fitting of dual ignition.

As to wheels, we have on the front the standard wear for Morgans of 1929 vintage with 19x4.40” tyres. On the back are standard GN “dog clutch” hubs with 18” well-base rims built on, fitted with 4.50” section tyres. I usually run the back tyres at 10-15lb/sq. Inch according to event and road surface. The fronts I run at 18-20 lb/sq.inch.

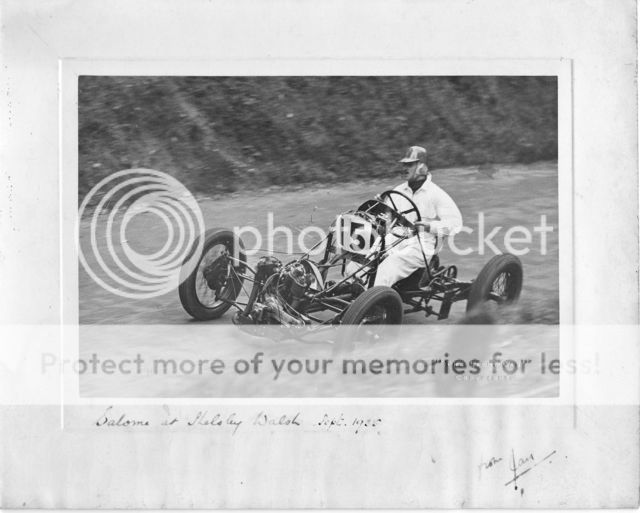

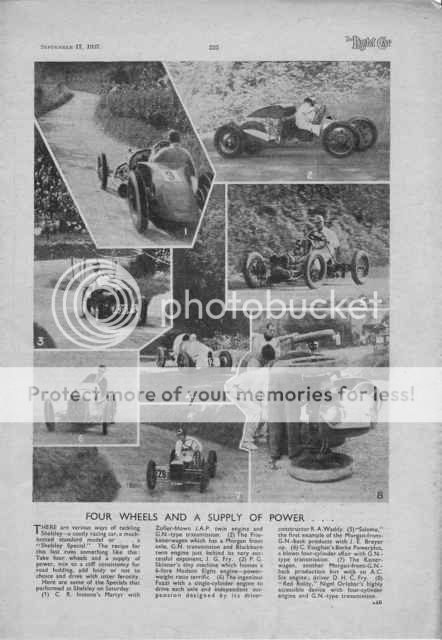

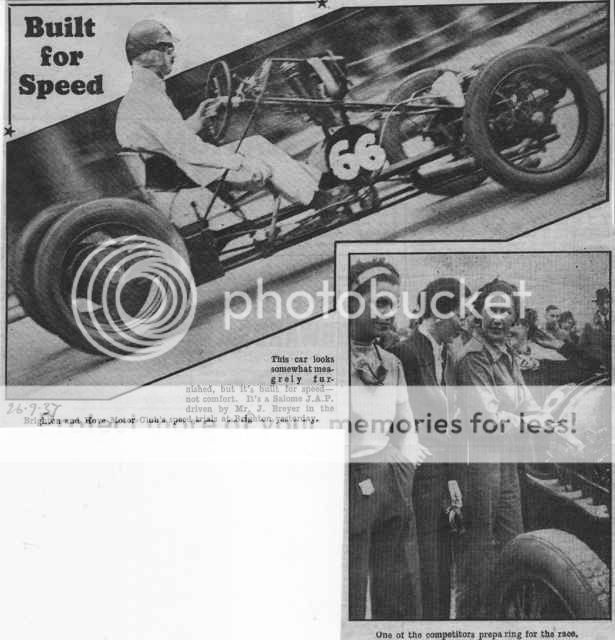

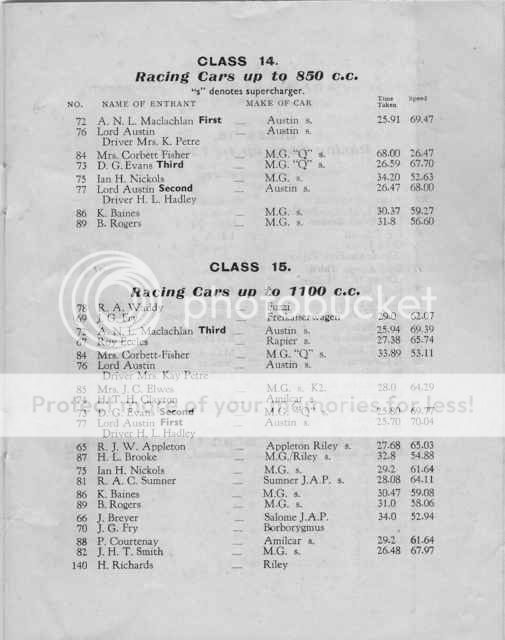

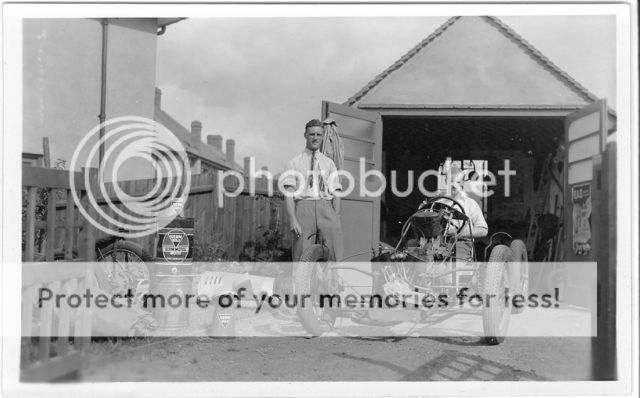

So, in September 1935, Salome appeared with a practically standard 8-30 J.A.P. side valve."

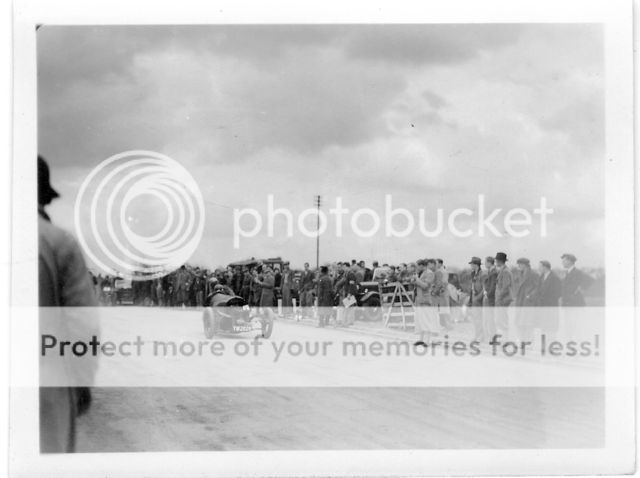

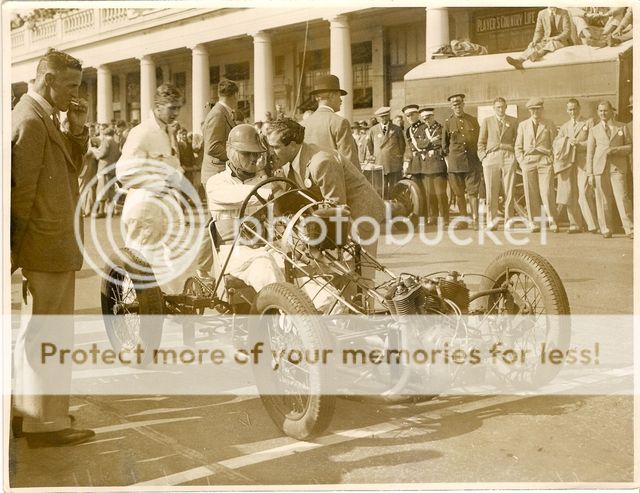

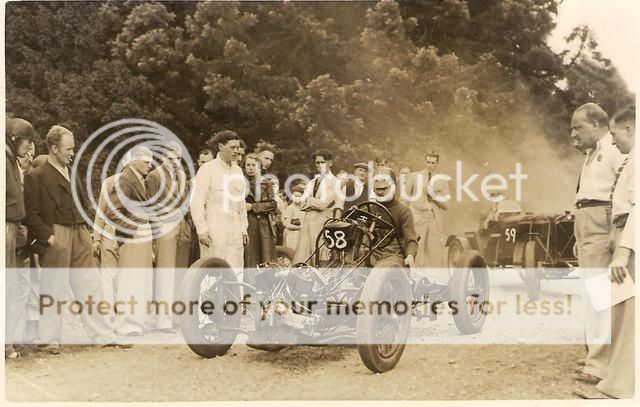

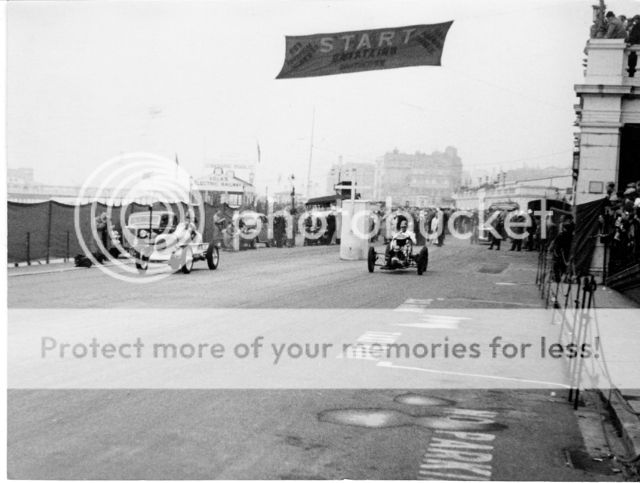

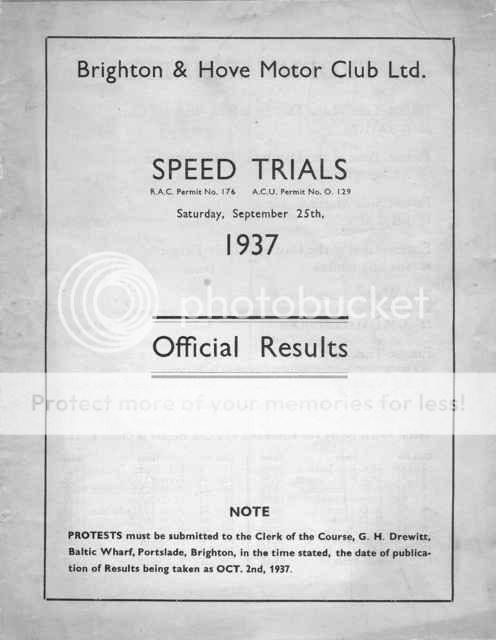

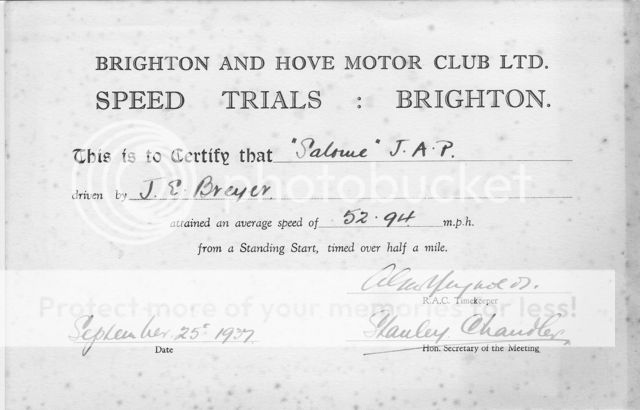

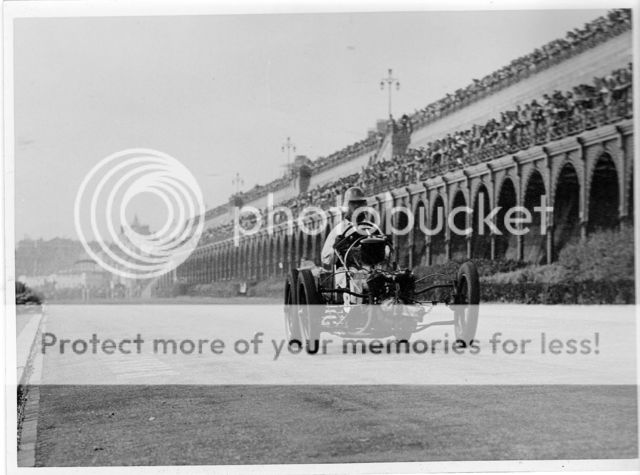

"Did the standing half mile at Brighton in 35 seconds, …..."

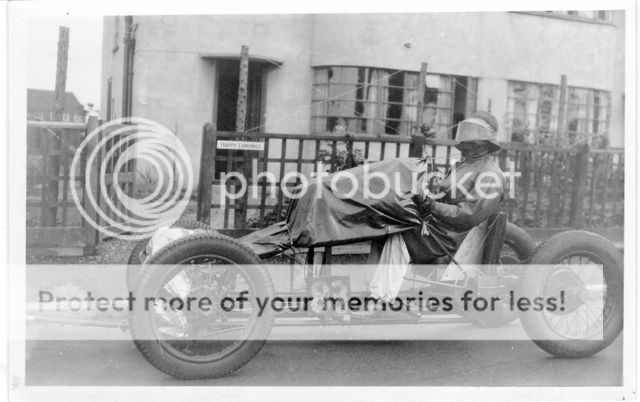

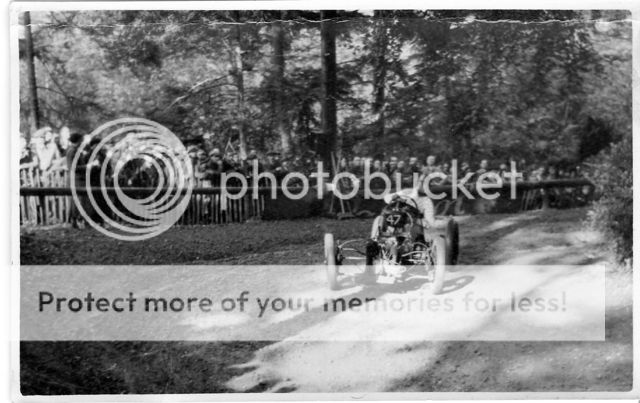

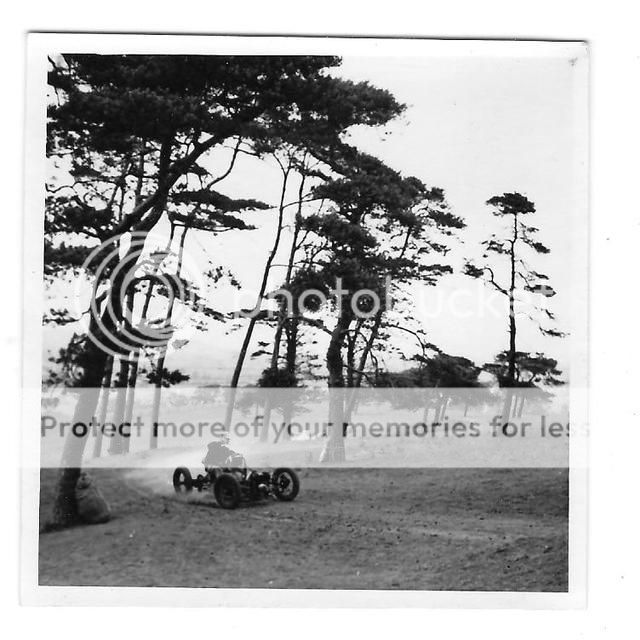

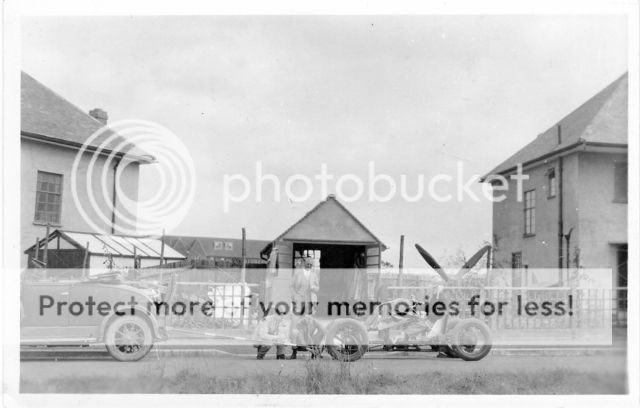

(Setting off to Brighton)

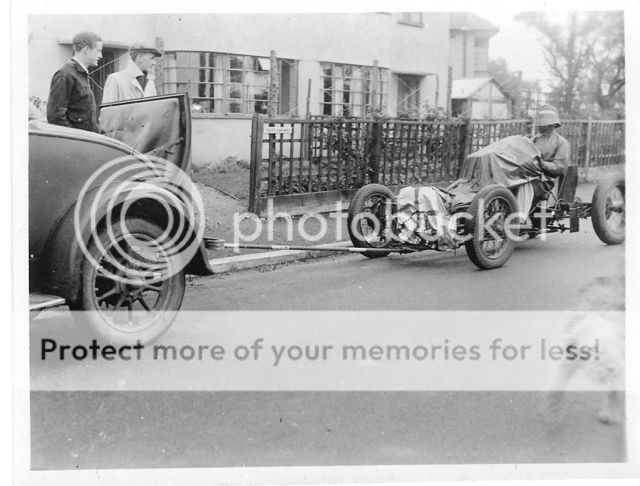

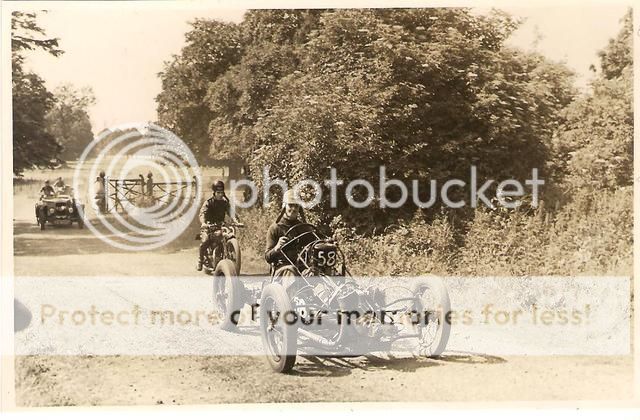

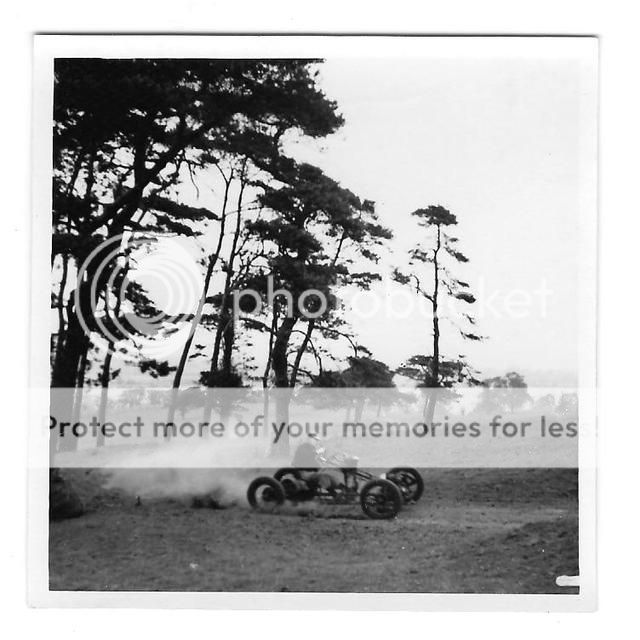

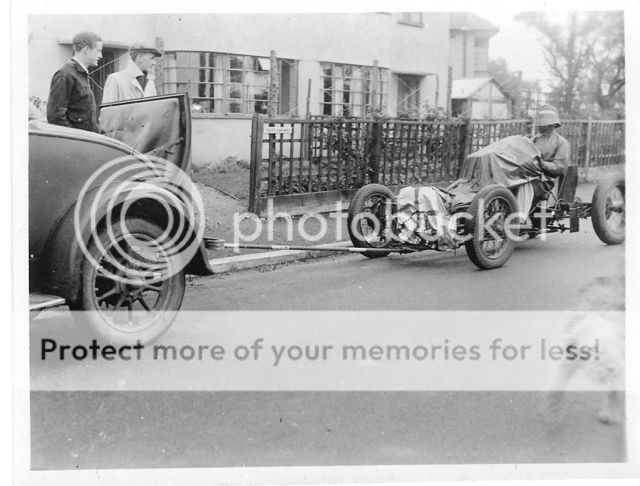

(En route)

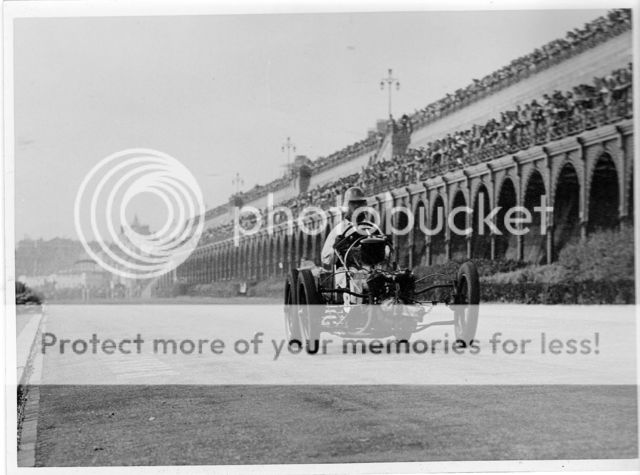

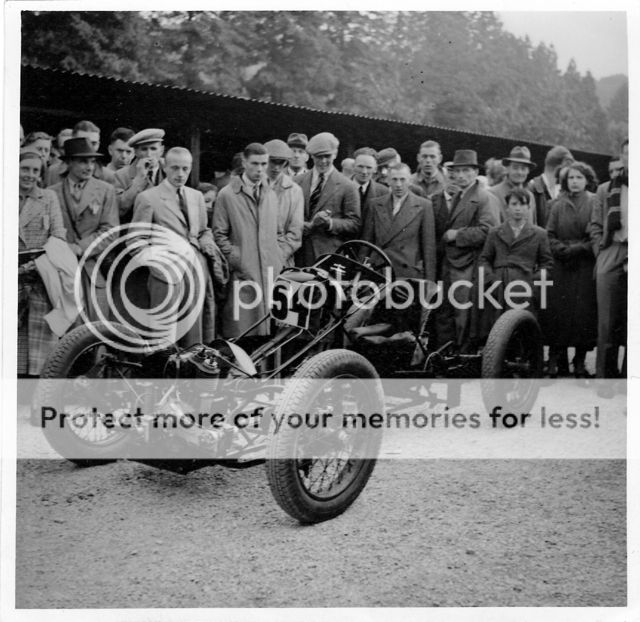

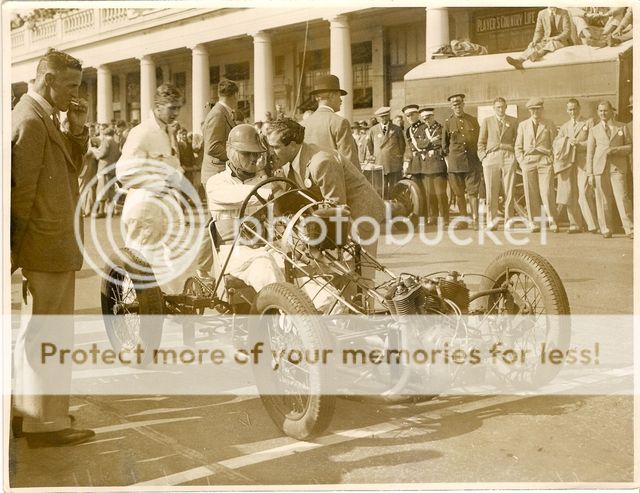

(Brighton Speed Trials, Madeira Drive, 14/09/1935)

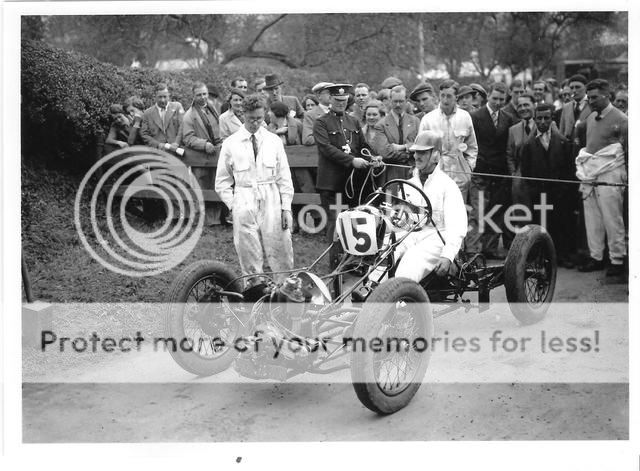

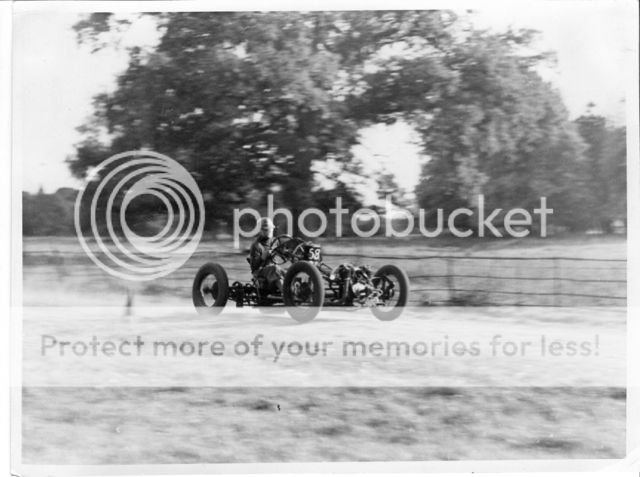

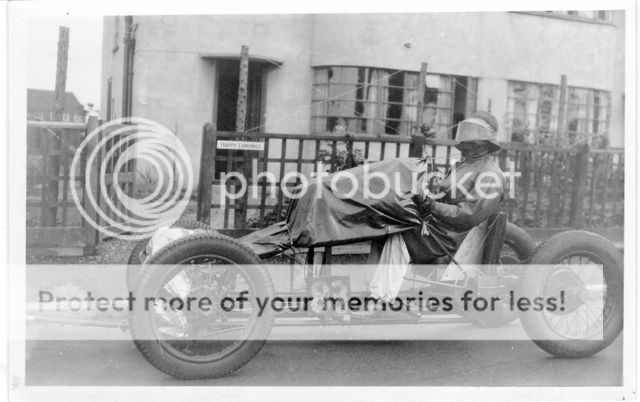

(Back home)

To be continued.

Edited for wrong spelling of Madeira Drive.

Edited by ratkinso, 20 October 2018 - 16:50.