Hello Gruntguru.

You write:

“Is there any difference in length of the engine measured along the cylinder axis - comparing a twin crank solution to the Pat OP or POC?

Otherwise the biggest difference seems to be a large rotating mass (Jumo, Achates) versus a large reciprocating mass (single crank solutions).”

With 64+64=128mm combined stroke, the single crankshaft PatOP prototype (635cc cylinder capacity, 850cc scavenge pump capacity):

has a total height of 500mm, including the built-in direct-drive scavenge pump.

With 50+50=100mm combined stroke, the two-crankshaft OPRE prototype:

has the same total “height” (500mm), including its two built-in direct-drive scavenge pumps.

I.e. the single crankshaft “pulling rod” opposed-piston architecture enables some 20% reduction of the maximum dimension.

Worth to mention here:

The built-in direct-drive scavenge pump of the PatOP, OPRE and OPRE_Tilting opposed-piston engines reduces not only the weight, the external dimensions and (substantially) the overall cost, but it also saves energy (consumed as friction in the gearing from the crankshaft to the scavenge pump of the typical opposed piston).

Think how simply and efficiently the piston-type scavenge pump of the pattakon opposed piston engines is driven: a part of the energy on the combustion-side of the piston passes directly to the scavenge-side of the same piston.

For comparison see the external scavenge pump of the Commer TS3 at right, and compare its size (and cost?) to the rest engine (its bore is shown at left) :

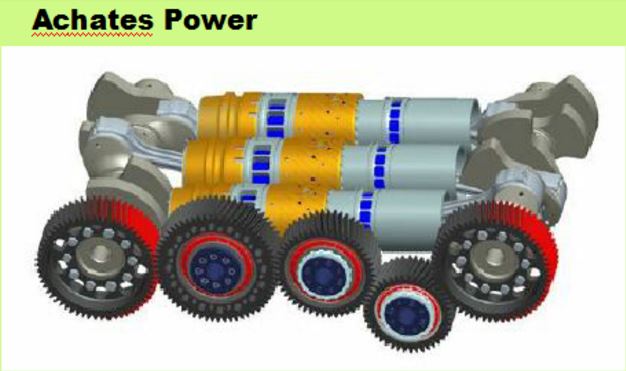

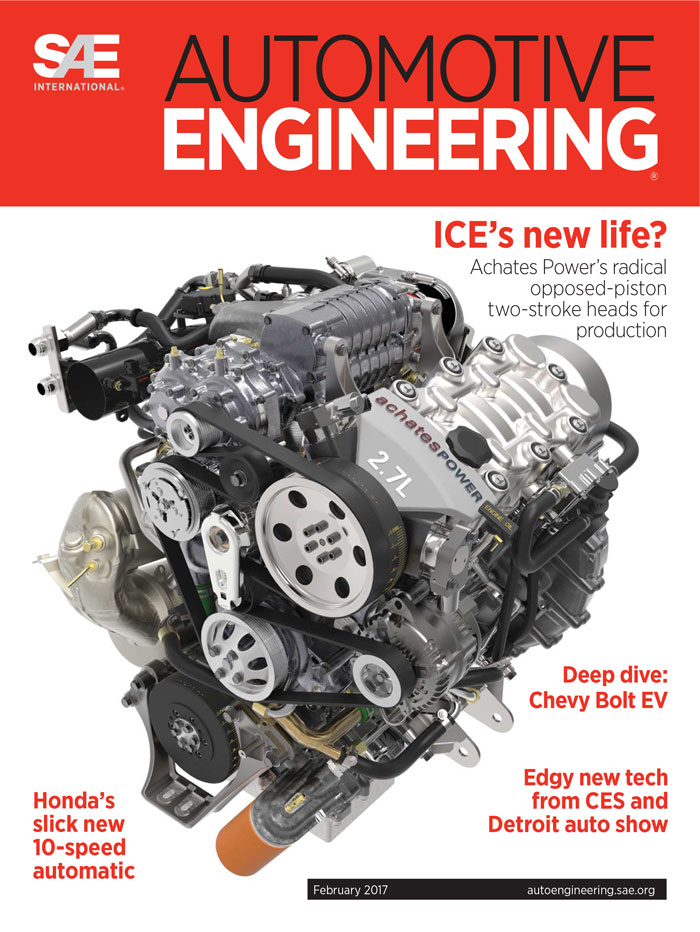

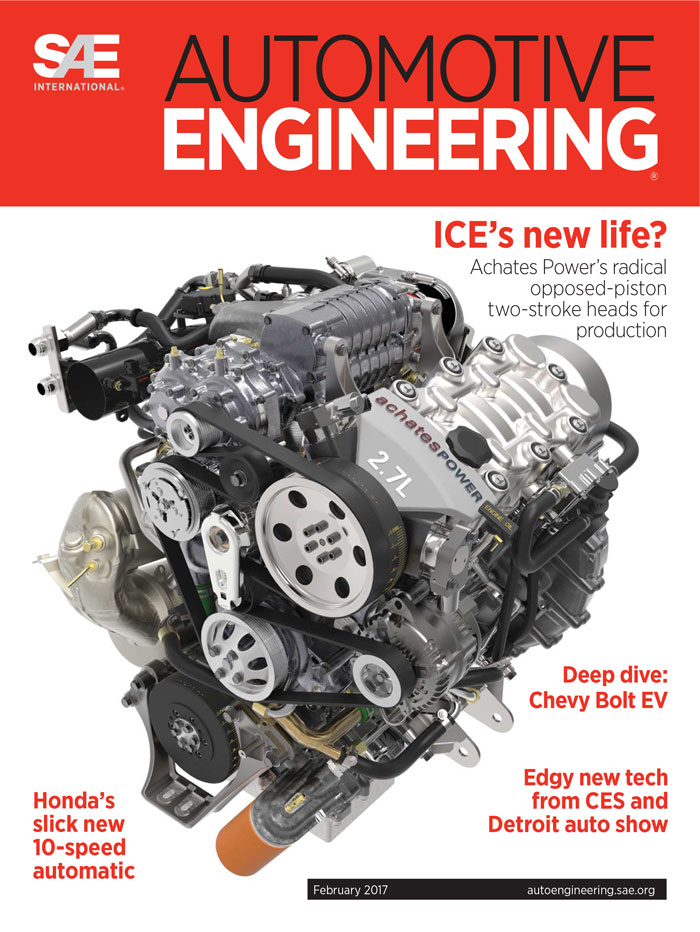

See also the external scavenge pump of the Achates Power 2.7lt (SAE announcement of 2017, for the production of the OP engine developed by Achates Power) :

The following quote was posted to another forum (March 2014) :

“A couple of years ago I wrote in “TheKneeSlider” where they were re-re-re-presenting the “promising” OPOC engine:

“In EcoMotors they have the funds, they have the publicity (every time a guy in EcoMotors “coughs”, every magazine in the world publishes -or reproduces- an article for OPOC), they have the support (only the name of Bill Gates “opens” every door). What they don’t have is a good engine design.

Unless I am wrong, after several years there is not yet an OPOC in a car or truck for tests by an independent third party.

Get in the place of the independent inventors / researchers / makers and think how they feel seeing in the press, again and again and again, about the OPOC of EcoMotors, about how many parts less than the other engines it comprises (which is a false claim), about how many less fuel it will consume (which is also a false claim), about how “green” it will be (which is also a false claim), and so on.””

Does the above remind something?

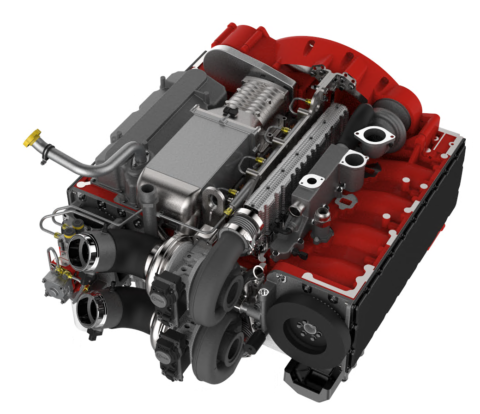

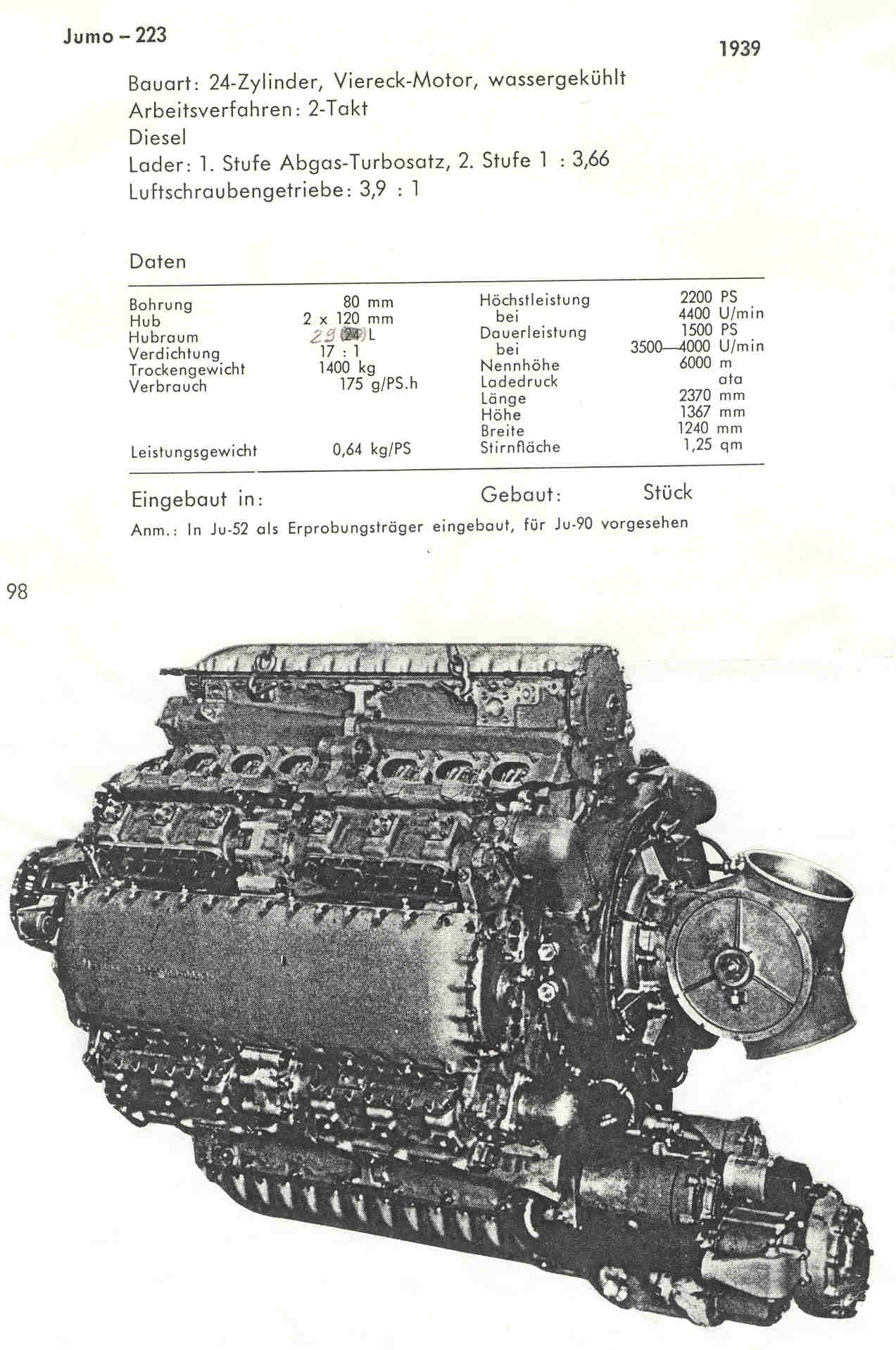

Differently: make a search on how many magazines and forums published articles about the Cumming / Achates Power combat engine (or about the rest Achates Power opposed piston engines), and reading the articles try to figure out what is the real advantage of these engines as compared to contemporary and older (Junkers Jumo) designs.

Thanks

Manolis Pattakos