Hi, this is not an automotive application, just a project I'm working on (and as is obvious I'm no mechanical engineer).

I have a small rod (5mm dia) that is being pushed over a distance of 11mm with a decreasing force and want to resist that force on the other side with a spring.

I figure I need a compression spring with a falling rate. Here is a rough force curve.

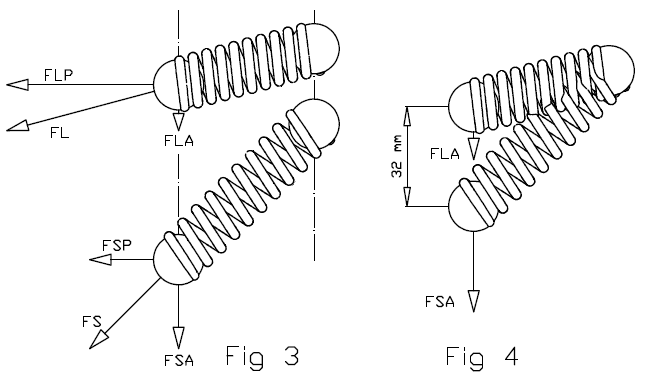

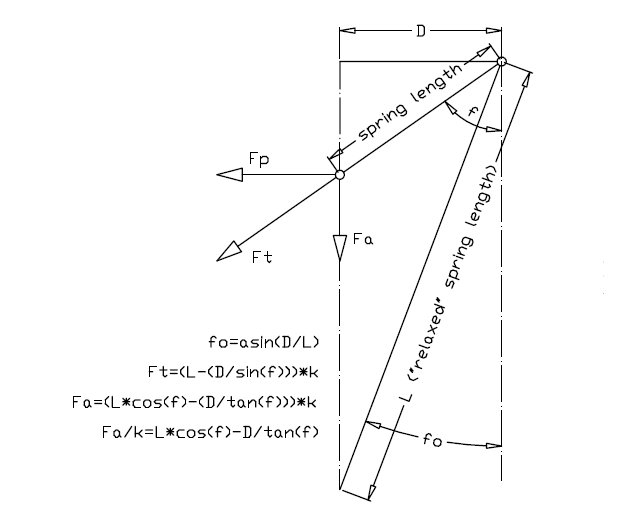

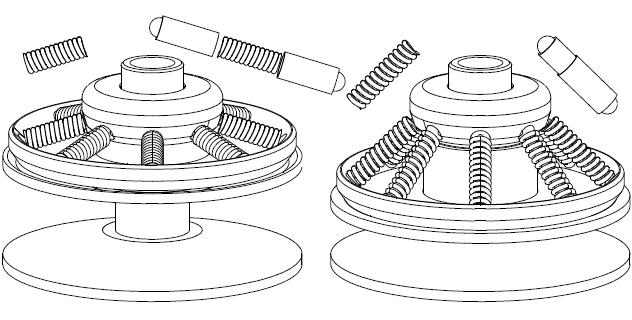

I found this solution, but not sure if it will work?

https://www.mwspring...ng-spring-rate/

I don't need to match my curve exactly so 2 or 3 individual rates would do.

Thanks ![]()