Suspension Engineering

#1

Posted 29 August 2006 - 04:37

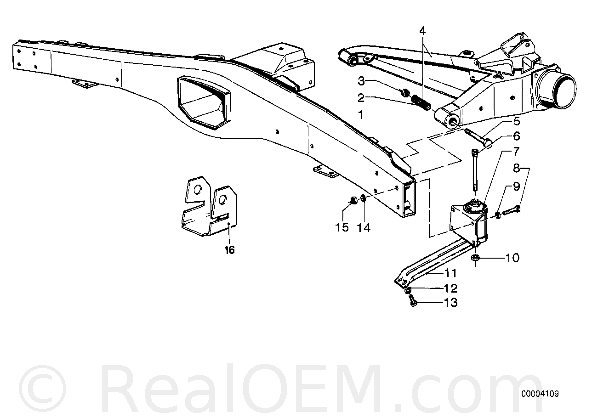

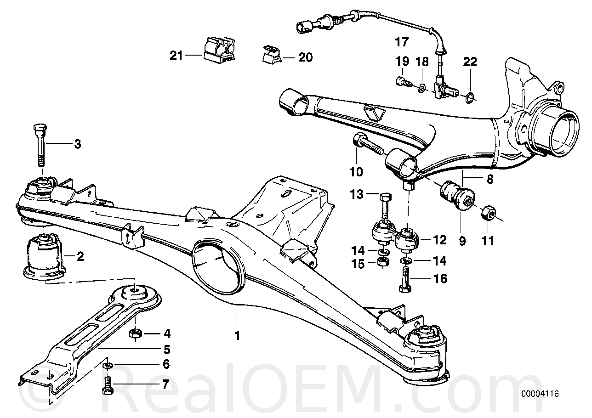

Short version - I have a limited slip differential from a later model BMW I'd like to install in my '81 - because I have it and the car currently has an open diff. For reasons of car-cancer, I need to do a bunch of body work within the trunk area anyway, including a new floor and repairing the stock diff mount. The diff I have is not a bolt-in though I suspect with a minimal of fuss I could machine up 3 new mounts and have it sitting pretty (shock locations are the same, hanger is different). Once I got that far into the plan, the Well, while I'm in here... disease kicked into full gear.

What I'd like to do - stretch both wheel-wells 1" on the inside, shorten the axle shafts the corresponding 1". Rather than fabbing up new mounts, replace the stock steel diff hanger entirely with an aluminium version - and while we're at it, the stock steel trailing arms with aluminium versions.

I'm fairly proficient with SolidWorks and can draw pretty much anything I need to, I can load it, bend it, twist it with COSMOS FEA and if I can't get my head around the machining, I have a very skilled team of people I work with that can. But - and it's a big but - I don't know how to ensure my new parts are strong enough, or conversely not over-built. Sure I'm not building a 1000hp turbo-charged monster but I don't want the diff parting company with the car, nor do I want to end up with an assembly that is heavier than what I started with.

Is there - and I'm ever so hesitant to even ask - a rule of thumb when re-designing steel parts in aluminium? Is there a set of formulas or rules to determine load forces and vectors based on the car's weight or some other factor(s) that I can reasonably determine? Do I need to hire an engineer to do this and live to talk about it?

Go easy now...

Advertisement

#2

Posted 29 August 2006 - 06:16

In the past I have said for road use use 5g vertically at the contact patch, and 3 g longitudinally (or say 4 ) and 2g laterally . For circuits, use 3 2 1 respectively. This is the 3 2 1 rule.

So if the corner weight is 460 lb and you are designing for road use then apply 2300 lb to the contact patch in Z, and work out all the stresses everywhere

Then, to be horribly crude add the magnitude of the maximum stresses from the other load cases and you should be well safe.

Those bits are a bit light for a daily driver.

Then you need to find out your material properties.

www.matweb.com

If I were you use 6061 T6 (280 MPa) or, preferably, T4 (145 MPa) and don't weld either at all, and think about stress raisers. If you want to weld it then you'll need a post weld heat treat, and then you'll have to cope with distortion. T4 is preferred due to ductility.

Real suspension parts are forged from aluminum A356, which is better than most billet stuff.

I can't really give you a scale factor for steel->aluminium as the beemer parts are likely to be something moderately nice - good steel is very cheap.

However, I think you could expect a 30% weight saving typically, for the same strength. (Would you bother for less?). Bear in mind that steel is a lot more ductile than aluminium, and we tend to design suspensions so they bend, not break (otherwise we get spanked in court). 12% elongation is a minimum.

Incidentally, knuckles in particualr, and in your case the semitrailing arm (I think) may well be stiffness limited, in which case you may find it tough to get much lighter than a steel part.

#3

Posted 29 August 2006 - 08:06

http://engineeringre..._page&PAGE_id=3

#4

Posted 29 August 2006 - 20:55

Isn't 1G lateral loading a bit low, even for non-aero cars? It's possible to generate more than that in steady-state cornering, with occassional spikes going well above 1?

Also, what is the resultant 'd' from the calculator you linked to? It is distance (inches), but distance of what?

Thanks!

#5

Posted 29 August 2006 - 21:02

#6

Posted 29 August 2006 - 22:31

I suppose they rely on inspection in the case of race cars.

I haven't used that calculator, i just found it yesterday.

#7

Posted 30 August 2006 - 00:18

So if I base the design on 5 4 2, given that it's a daily-driven road car subject to all the manhole covers, potholes and occasional road debris one might expect, I should be within a reasonably safe realm then?

When you say the arms (pic below) are stiffness limited, I'm not really sure what you mean. Do you mean that building an aluminium version with the desired elongation and stiffness factors would end up being the same weight as a steel version?

I'm not sure yet if I can get away with narrowing the track width anyway and if I can't it sort of sends the whole thing in a different direction. I haven't had a chance to measure everything out and see if the arms can also be moved as-is 1", or if the new axle-shaft angles will funciton properly.

Looking at some different materials, 6033-T651 has a Tensile Yield MPa of almost 400 and elongation of 13%, vs. the 6061-T4's of 25%. Even with the greater strength of the 6033, the ductility of the 6061 is the over-riding factor? Of course it may be that 6033 can not be had in the desired shape and size, or may rival AlBeMet for cost for all I know.

#8

Posted 30 August 2006 - 02:31

Since you're not re-doing the whole chassis there's no point in inventing your own unique set of performance requirements just for those few pieces anyways.

#9

Posted 30 August 2006 - 02:33

5 4 2 is fine

Your pictures didn't work.

The ratio of young's modulus to density is identical for steel and aluminium, so quite often it is hard to beat steel for stiffness per unit weight. Even a realistic carbon layup (in 3 dimensional strain) won't be that far ahead. That is, if you were to put as much effort into designing the steel part and cost into building it, you might well end up ahead.

A good example of this is small roadwheels - aluminium ones often end up weighing more than steel ones, which actually have better properties in some respects. As the size increases over 15" aluminium usually wins, but the optimum is steel rims on an aluminium spider.

#10

Posted 30 August 2006 - 03:22

I know of a case when a guy got a few tumbles in a car when the front knuckle was designed for 1 lateral g and it broke. Also, I once recorded 7 vertical g's at the C.G. when driving on some wavy road. That was a lot of fun! Glad that was not my own car.Originally posted by Greg Locock

I agree that 3 2 1 is a bit light, but it is accepted practice for non aero cars, many race cars and prototype road cars are designed using 3 2 1. Our solar cars were designed using 3 2 1 and for the most part have survived for 3000-9000 km (admittedly on smooth roads) without suspension cracking.

#11

Posted 30 August 2006 - 03:22

In the car currently:

E12 Rear

In the $400 donor car:

E28 Rear

In looking at the trailing, or semi-trailing (what's the difference?) arms - if I move the inboard leg of the arm (now there's a phrase) towards the outside, effectively making the angle at the hub between the two arms narrower, what effect does this have?

#12

Posted 30 August 2006 - 05:16

Those are almost pure trailing arms, with just a bit of semi to give them a camber curve, and as a free bonus some bump steer, understeer (which you might want, due to the next paragraph).

Moving the inboard bush outboard will reduce the lateral and toe stiffness of the suspension, giving you even more compliance oversteer. That is nasty and inevitable. If it annoys you too much consider adding a toe link behind the wheel, say to the back of the diff, or up to the chassis rail. It'll fight the other arm so you'll have to put some compliance in somewhere, which will bugger your camber stiffness.

Now, the other interesting thing is what happens when braking and accelerating. The wheels will tend to steer, toe in when accelerating, toe out when braking. The latter will make it darty.

Hope you are enjoying all this, this is why it is hard to make refined semi trailing arms. The advantage of a semi trailing arm is that it is cheap, compact, strong and sensible. Not elegant.

#13

Posted 30 August 2006 - 07:06

A pure trailing arm would have an angle of theta = 0 deg. The E30 trailing arm angle is 15 deg. Some refer to this as the "sweep" angle.

I need some help understanding this still - what is 15' to what?

As suspected I'm in way over my head. But I'm liking the learning.

#14

Posted 30 August 2006 - 09:33

The not-trailing arm (bottom... yeah... made that up... effectively a swingaxle) pivots on a longitudnal axis, has LOTS of camber gain.

The semi-trailing arm (middle), being in between, has some camber gain

#15

Posted 30 August 2006 - 22:35

x is longitudinal (back), y is lateral(right), z is up

#16

Posted 30 August 2006 - 23:32

(you could try grafting in something much nicer, like an Alfetta de Dion)

#17

Posted 31 August 2006 - 02:02

#18

Posted 31 August 2006 - 04:37

In the future, perhaps an SLA design is a better idea. Or not - I still know **** about suspension.

#19

Posted 31 August 2006 - 22:42

Advertisement

#20

Posted 01 September 2006 - 00:42

In looking at the pictures above, would you a) leave everything as is with the open diff, b) modify the stock hanger to accept the LSD diff or c) mount the new hanger and diff (and arms) as an assembly?

#21

Posted 01 September 2006 - 02:40

#23

Posted 02 September 2006 - 08:52

#24

Posted 02 September 2006 - 11:31

Semi-trailing arms give camber change under the following conditions: acceleration, braking, cornering and bump. With wide tyres this geometry arbitrarily changes the contact patch from middle to edge. With all cars except (apparently) BMW, semi trailing arms lead to unpredictable behaviour (unless you count unpredictabilty as predictable). All reviews I've read of semi-trailing arm BMWs stress their tendency to oversteer.

I would very much like to know what makes BMW semi-trailing arms so good. Please enlighten me.

#25

Posted 02 September 2006 - 12:59

Originally posted by soubriquet

I want to get this straight.

Semi-trailing arms give camber change under the following conditions: acceleration, braking, cornering and bump. With wide tyres this geometry arbitrarily changes the contact patch from middle to edge. With all cars except (apparently) BMW, semi trailing arms lead to unpredictable behaviour (unless you count unpredictabilty as predictable). All reviews I've read of semi-trailing arm BMWs stress their tendency to oversteer.

I would very much like to know what makes BMW semi-trailing arms so good. Please enlighten me.

#26

Posted 02 September 2006 - 13:13

Camber thrust from modern radials is only about 5% (that is, if the tire produces say 1 kN of sidethrust per degree of steer, then it'll produce about 50 N of sidethrust per degree of camber). This is less than a quarter of what old crossplies made, so camber thrust is less important than it used to be.

Traditionally you set up a semi trailing arm to have lots of kinematic bump steer (toe in in jounce) to compensate for the compliance oversteer. The problem with that is that your compliance oversteer comes in as soon as the tire starts to bite, whereas you'll only get the compensating kinematic steer after the body has started to roll.

So, the answer is probably that they do something at the front to compensate. I've often found it useful to plot the buildup in forces in the suspension members as a result of a step steer event (Milliken shows some real data on this) - from this you can see what is likely to help to smooth out the response. If you keep the front roll centre low then you can begin to synchronise the body roll and the rear end response, for instance. If you get the body to roll fast enough then you could get the rear suspension to move into jounce before the rear wheels have started to develop sidethrust. Also you've got to consider the relaxation length of the tire - that gives you another few milliseconds.

Also bear in mind that continual development of a second rate architecture can give good results. Look what they do with Macpherson struts, for instance.

#27

Posted 04 September 2006 - 10:05

The first and last paragraphs are perfectly clear to me. I understand entirely who it is that puts food on the family table, but when dealing with McPherson struts, aren't we also inextricably linked with the F word?

I'm no engineer, simply a punter. The nicest road cars I've had were/are a Lancia Beta Coupe and a series of Subaru Liberty/Legacy wagons. Both have struts on all four corners. What am I missing here?

#28

Posted 04 September 2006 - 23:54

Nothing for road cars with narrowish tires. But if you really want to control the presentation of the contact patch to the road then you have to be able to set your camber gain (deg camber per degree of body roll) at will. MacPherson won't let you do that, except for one corner. Bear in mind that MacP does some things very well, so when you are building a car and start to make the inevitable compromises, a MacP gives you a fair bit of wriggle room (particualrly with budget and weight) that a posher suspension would not. For instance, the cost advantage is so big, I can say, OK I'll accept the MacP, but you have to give me hydrobushes in return. So the customer might end up with a better overall car, even if the suspension engineer is grizzling into his beer because he didn't get his twin wishbones.

The trick is to take a system that works for small cars with narrow tires, and still make it work for big cars with wide tires. In the world of suspension we look at BMW and occasionally think, now why on Earth did they do that? It has usually been instructive to find out why. I think BMW do drop the ball in other areas (to some extent), but their suspension guys seem to have enough clout and nous to make their chassis successful.

#29

Posted 05 September 2006 - 01:01

Greg, you seem have figured out some rule of thumb about the MacPherson suspension. Are you saying that in a turn a MacPherson inside front will always have a very unfavorable camber and no large strut inclination, caster or KPI can fix it?Originally posted by Greg Locock

But if you really want to control the presentation of the contact patch to the road then you have to be able to set your camber gain (deg camber per degree of body roll) at will. MacPherson won't let you do that, except for one corner. ...

The trick is to take a system that works for small cars with narrow tires, and still make it work for big cars with wide tires. In the world of suspension we look at BMW and occasionally think, now why on Earth did they do that? It has usually been instructive to find out why. I think BMW do drop the ball in other areas (to some extent), but their suspension guys seem to have enough clout and nous to make their chassis successful.

Touring BMW's, just like Porsches, turn on 3 wheels. But those GT BMW's with really wide front tires stay on all four through the corners and still seem to be going really well! Have you figured out some secret? Is their front geometry just set up for one corner at a time?

#30

Posted 05 September 2006 - 04:58

However just thinking about circuit cars. If they are turning at roughly the same g's on each corner, they'll have the same body roll. So, by stuffing around with static camber enough they can at least set the outer wheel up to give the correct camber compensation for that lattac.

With a bit more hack work you could look at the height of each end of the lateral arm, then you could get some curve into the camber gain curve, and maybe start to get the relationship between the inside and outside wheel right. To be honest I haven't even got a simple spreadsheet model of a MacP, but if you've only got three conditions to tune for (left turn at 1g, right turn at 1g, straight ahead) and are prepared to live with some disgraceful antics in the transition between those 3 conditions, I'd have thought you could do it.

#31

Posted 05 September 2006 - 05:10

#32

Posted 05 September 2006 - 05:40

#33

Posted 05 September 2006 - 16:39

#34

Posted 29 October 2008 - 18:35

I'm coming back to this thread just as a starting point, primarily because it contains the information for my present setup. I'd recently PM'd Greg about going to A-arms front and rear in the car but abandoned the notion when it occured to me that my ignorance and I were unlikely to better the product that a team of German engineers put together. But...

If we go way, way back, Omar K (who's board name escapes me at the moment) joking suggested replacing the stock power plant with a later V12. That notion has been ticking in away in the back of my mind since that point. Despite dismissing it on a number of occasions for lack of quantifiable purpose, I'm beginning to draw up concepts again, especially in light of the collection of E12s I seem to be amassing.

Think Pro-Touring for lack of a better description - A/C, tunes, a back seat for the kids (or the wife and I ;) ), plenty of power, plenty of rubber, still goes around corners. The V12 is a given unless a late-model M5 V10 falls into my lap for a lot less than the $18k I've seen them for. Not only has a small-block in an E12 already been done (more than once), a small-block has been done so often it's cliche. Which brings us to the subject of my post - the rear end. Earlier in this thread, Greg suggested narrowing the subframe to bring everything to allow for more rubber. I crawled around under the car the other day and started taking measurements but the first thing that crops up is the proximity of the inner trailing arm mounts to the diff mount. Best case scenario, I might manage to narrow the assembly by an inch...maybe. I could mount up a narrowed Ford 9" or GM 12-bolt but those are equally cliche. Thus, we're full circle to the A-arm IRS idea.

In digging around for ideas, I came across some little outfit called Team321 and was looking at this iteration in particular.

My thoughts were to utilize an existing BMW diff from the later E28 and build the rest of the system around that. I'm wondering however about mounting the new subframe to the vehicle. The current system is held in place via rubber bushes from subrame to body and a single one from the top of the diff to a crossmember under the trunk. Would a 3-point system suffice to mount a system similar to the one above? In the stock system, there's also the struts of course, which would be self-contained in the IRS sub-unit, no longer offering connection to the body. I'm thinking additional crossmember(s) are probably prudent, perhaps tied into the bumper mounting area but then I think that the body is resting on the mounts, not the unit hanging by them. Input?

#35

Posted 29 October 2008 - 20:10

Secondly, and absolutely no pun intended at all, (I bodge things up my self)

I wonder what´s the reason for building a suspension with components under more or less pure bending (upper arm)?

I understand that aero considerations might prompt such a contraption, but in a super saloon?

R

#36

Posted 29 October 2008 - 22:15

Canuck - you very slightly give the impression that I agreed that you couldn't better a BMW semi trailing arm, my attitude was more that for road use it wasn't worth the hassle, the STA works well enough.

#37

Posted 29 October 2008 - 23:45

I picked the IRS in question for no particular reason. In fact it was suggested I go with a lote-model Mustang Cobra IRS and indeed they are reasonably plentiful due to folks pulling them in favour of a straight axle for drag racing. The one or two units I did manage to see in pictures appear to be more complicated than the IRS above. I went with what I "got" first (I wouldn't say I understand it, but I get how I could fit it under my car for the most part).

I'm open to any other input folks might have - I'm certainly outside of my comfort zone and don't have a problem admitting it.

#38

Posted 30 October 2008 - 02:48

Originally posted by REN_AF1

First post, So, Hi to all of you..

Secondly, and absolutely no pun intended at all, (I bodge things up my self)

I wonder what´s the reason for building a suspension with components under more or less pure bending (upper arm)?

I understand that aero considerations might prompt such a contraption, but in a super saloon?

R

Packaging, low CG, mass closer to center, ratio's easy to change. As Greg says, the bending and pivot load is a simple engineering problem - use more material!

#39

Posted 30 October 2008 - 09:47

Advertisement

#40

Posted 30 October 2008 - 10:37

Originally posted by Greg Locock

, but, like most rear suspensions, it lets the wheels go up and down.

#41

Posted 30 October 2008 - 11:11

Did you mean it needs bearings in the upper arms due to the shock linkage/loads? I was wondering about bearings in the arms (as opposed to bushings) anyway - the stock subframe is connected to the car body entirely via rubber mounts. Assuming similar mounting for this IRS, would bearings in the arms have a significant negative impact on NVH (typically speaking)?