Speedman: “A really very very intressting engine construction for a two stroke engine. Reed valve is a little bit variable, you system static. And the 2-stroke engine have emission problem.”

What causes the emission problem of the conventional two-stroke engines is the unburned air-fuel mixture that inevitably escapes through the exhaust port during the scavenging of the cylinder, and the lubricant inside the combustion chamber (the MIT article at

http://www.pattakon....ssionDiesel.pdf explains how).

The Diesel engines (and the direct injection gasoline engines) avoid the first cause of the emission problem by scavenging with air and not with air-fuel mixture.

Quote from post 16:

“In the USA the EcoMotors (funded by "the" Bill Gates, among others) and the Achates Power (funded by "the" Walmart, among others) deal with 2-stroke opposed piston Diesels and how to reduce the exhaust emisions in order to use them in automobiles and trucks.

It seems the 2-stroke is not dead.”

All the effort is to reduce the lubricant that is left to enter the cylinder.

For EcoMotors things are difficult; despite their several patents regarding the “handling” of the lubricant, the fact remains that their pistons have to apply significant thrust loads onto the cylinder liner above the intake and, worse even, above the exhaust ports. Imagine a piston skirt thrusting heavily on the “almost dry” from lubricant hot “bridges” between the exhaust ports.

In Achates Power they claim a peak brake thermal efficiency of 45% for their opposed piston (“crosshead”) di Diesel engine prototype; they also claim a specific lubricant consumption of only 0.1gr/KWh (lower than many reputable four-strokes). They also claim that their engine complies with the current emission regulations.

What has to be proved in practice (in the long term) is the scuffing resistance of their design.

Their lubrication is “like-four-stroke”.

“Like-four-stroke” is the lubrication used in the PatOP and in the OPRE “crosshead” opposed piston Diesel engines of pattakon at

http://www.pattakon.com .

The term “like four stroke lubrication" is now used by the Primavis for the lubrication of their two-stroke gasoline V-90 engine wherein the one cylinder is used as the scavenging pump of the main cylinder. The V-90 arrangement improves the balancing of the Primavis engine.

On the other hand, the PatMar engine (and the PatPortLess engine for higher rpm) presented at the pattakon web site are two-strokes with TRUE four-stroke lubrication and TRUE four-stroke scuffing resistance.

They are “through scavenged” (uniflow) without ports on their cylinder liner.

There is no reason for having worse emissions than the state-of-the-art four strokes.

On the contrary, there are reasons for having lower specific lube consumption and lower specific fuel consumption than the current four-strokes.

Quote from Wartsila’s Technical Journal of Feb 2010 (the complete article is at

http://www.pattakon....nal_02_2010.pdf

“A slightly more ambitious idea is to apply the four-stroke trunk piston engine cylinder lubrication concept to the two-stroke crosshead engine, i.e. to “over-lubricate” the cylinder liner, apply an oil scraper ring, and then collect the surplus oil, clean it, and recycle it. This will of course be a radical change of concept, and whether or not it is viable remains to be demonstrated, but an outline exists and a patent is pending. The aim is to increase scuffing resistance and to achieve the same low specific oil consumption as on the four-stroke trunk piston engines.”

The PatMar is the solution of the problem set by Wartsila.

By the way, Wartsila is "a global leader in complete lifecycle power solutions for the marine and energy markets".

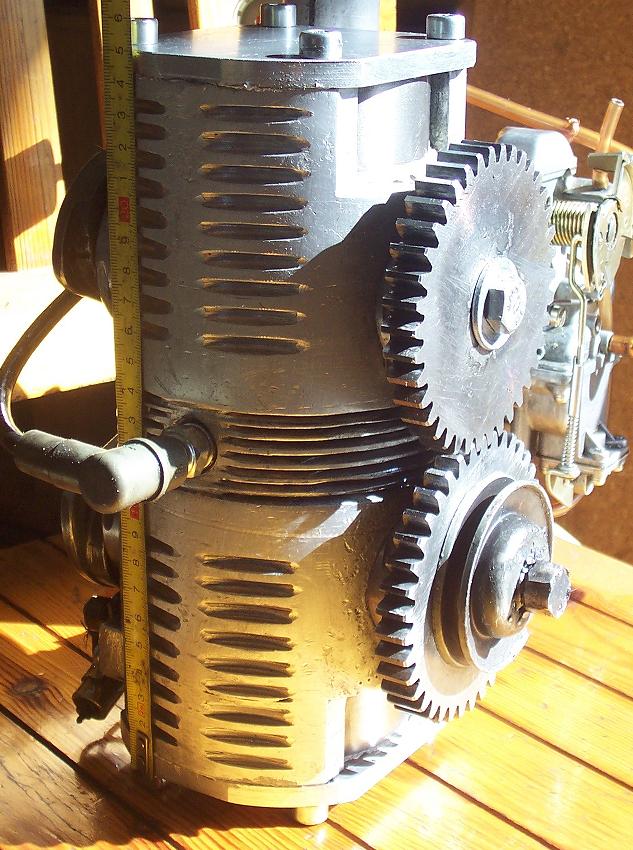

Speedman: "What is the liter capacity (PS/L / HP/L) of this tilting valve engine?

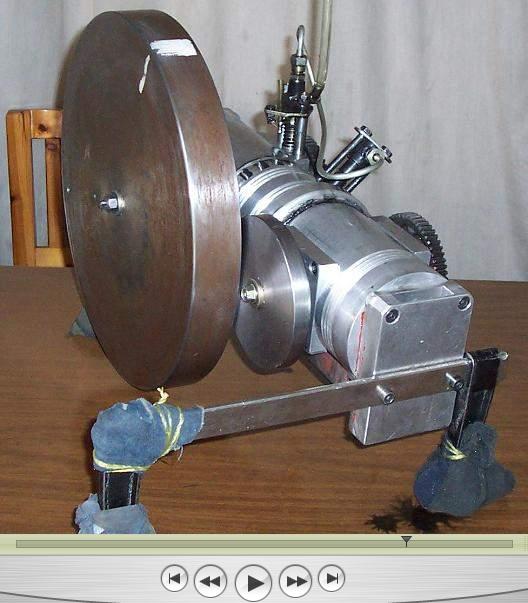

The specific power of the OPRE tilting is not known, yet.

Theoretically speaking, it has all the characteristics for top specific power (bhp/lit).

The state of the art two strokes (snowmobiles etc) have a peak specific torque of about 200mNt/lit (20mKp/lit).

Lets make a simple calculation:

With only 150mNt/lit (15mKp/lit) of torque for the OPRE tilting engine (i.e. with only 75% of the existing 2-strokes peak specific torque), the OPRE will provide:

15*1.4*6= 126bhp/lit at 6,000rpm (i.e. 42bhp from 333cc)

15*1.4*10= 210bhp/lti at 10,000rpm (i.e. 70bhp from 333cc)

15*1.4*15= 315bhp/lit at 15,000rpm (i.e. 105bhp from 333cc)

At 6,000rpm the speed at the edges of the 1m diameter propellers of the OPRE tilting Flyer is about 10% lower than the sound velocity; and the mean piston speed of the pistons is only 6m/sec, wherein the reliability is maximized. In the giant low-speed marine two-strokes, the 6m/sec mean piston speed is where the time between overhauls maximizes.

At 15,000rpm (which seems an extreme speed) the mean piston speed of the OPRE tilting 84x(30+30) is only 15m/sec (for comparison, the mean piston speed in a car engine having 90mm piston stroke and revving at 6,000 rpm is 18m/sec).

On the other hand, for several applications (like a flyer or a paraglider or a small airplane or helicopter) more important than the power to capacity ratio (specific power) is the power to weight ratio (bhp/Kp) wherein the OPRE tilting is even better.

The perfect balancing (vibration free) of the OPRE tilting is for free: it needs neither balancing shaft, not gearing. Compare it to the existing two or four stroke engines.

Thanks

Manolis Pattakos