Hello Manoli

I know your website since few years. Your website is very interesting. I am interested almost 35 years with internal combustion engines. I know very very much combustion engine patents, variable valve timing systems, variable intake systems and transmission systems, and CVT-Gears. I made earlier ecu-tuning tools, today no longer. I have even a model engine (webra) with rotary valve engine (cross valve) and many other model engines (two stroke, four stroke an a wankel engine)

My english is too bad for a good explanation of the rotating seal. But I try it anyway.

The most rotary valve system have a big problem with sealing. Rotary valve system with rotating tight body (in my case or DVL) have absolutely no sealing problem. The DVL engine have another problems but absolutly no sealing problem. This engine has a perfect sealing.

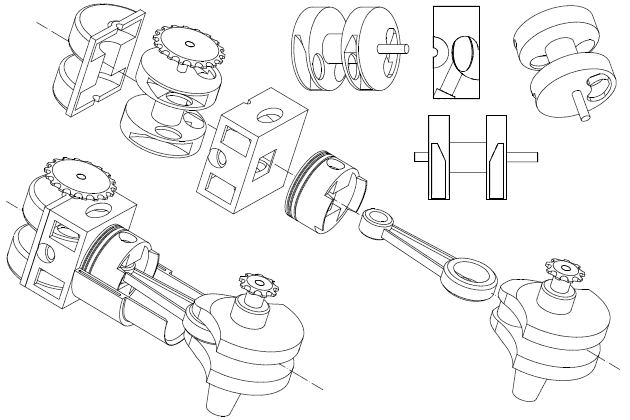

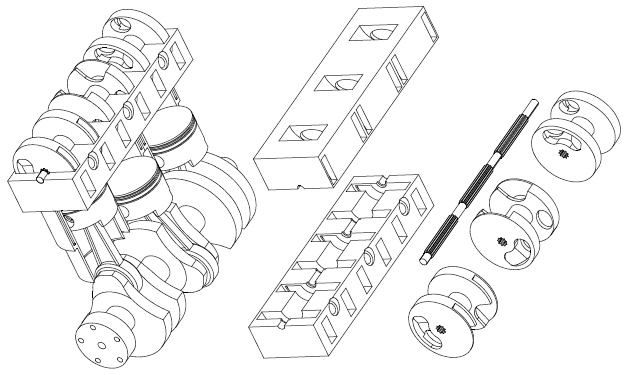

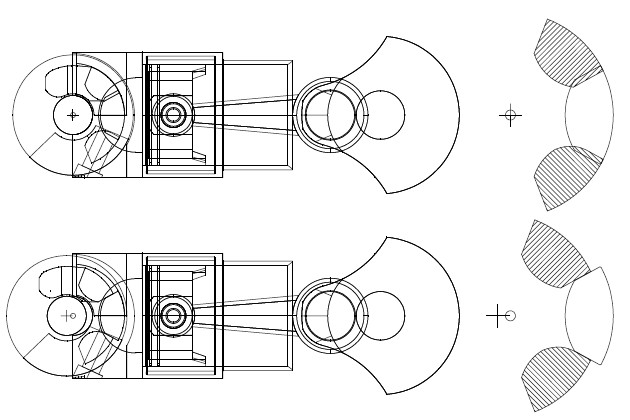

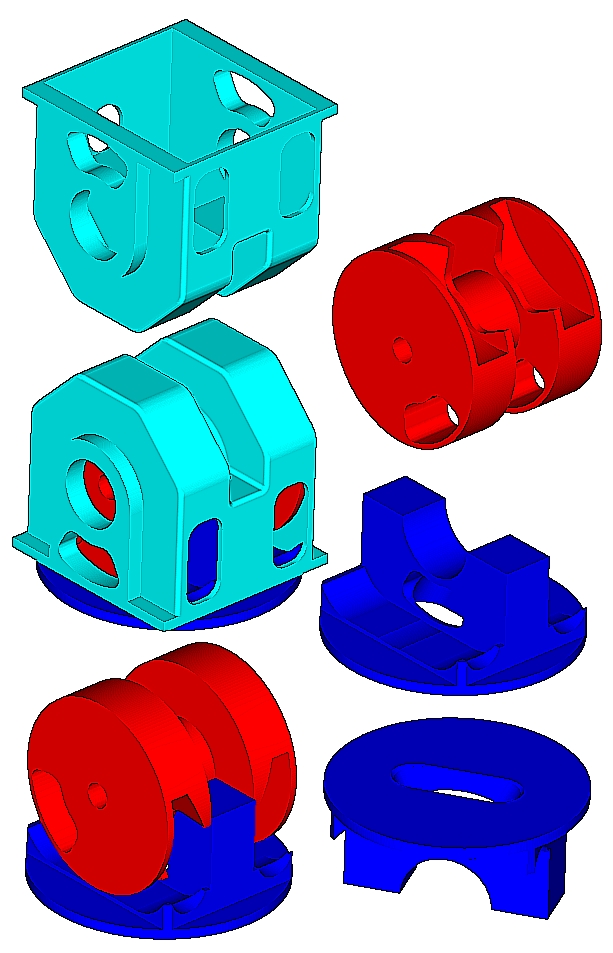

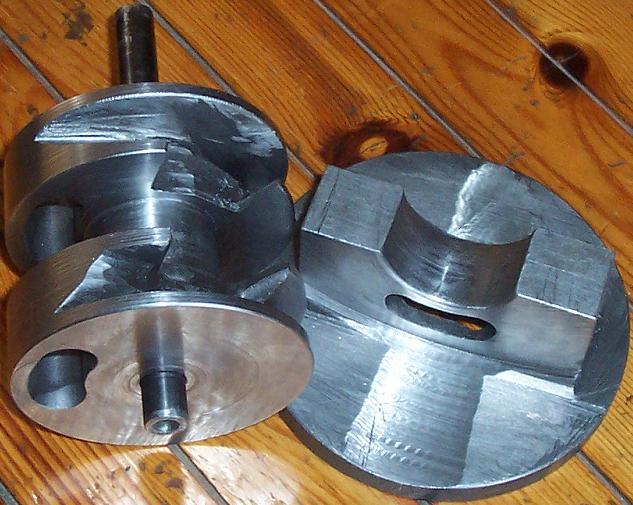

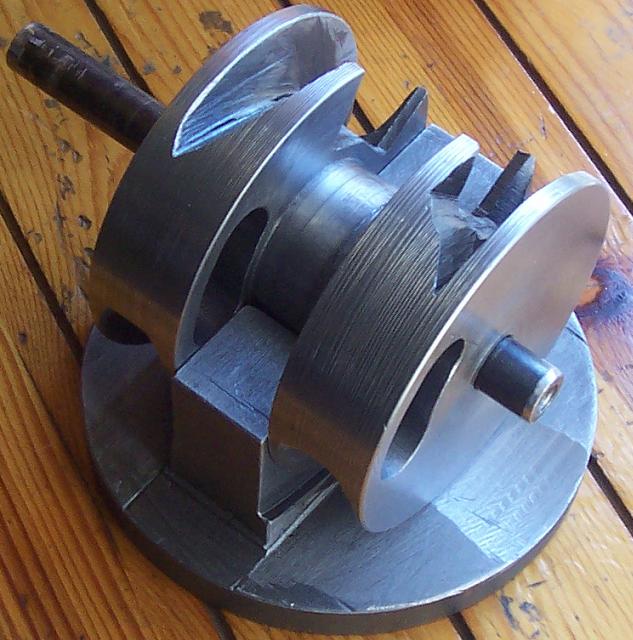

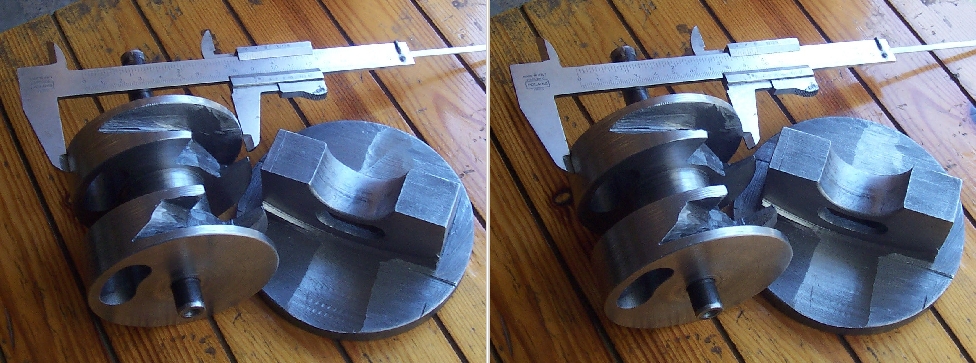

Two draws but two various engine with the same valve system.

Usually rotary valve engine is grains of sand, dirt or combustion residues a big problem, the valve is then leaky. By rotary seal is this no big problem. The rotary seal polished/grinds/lapping the wear away. The seal is every tight. Is it very importent the the seal rotaing. The lapping-effect is only rotary seal possible. Does the o-seal no rotate, then is the valve soon leaky. With modern material you need little oder no lubrication in den seal. For example: crystalline graphite need no lubrication.

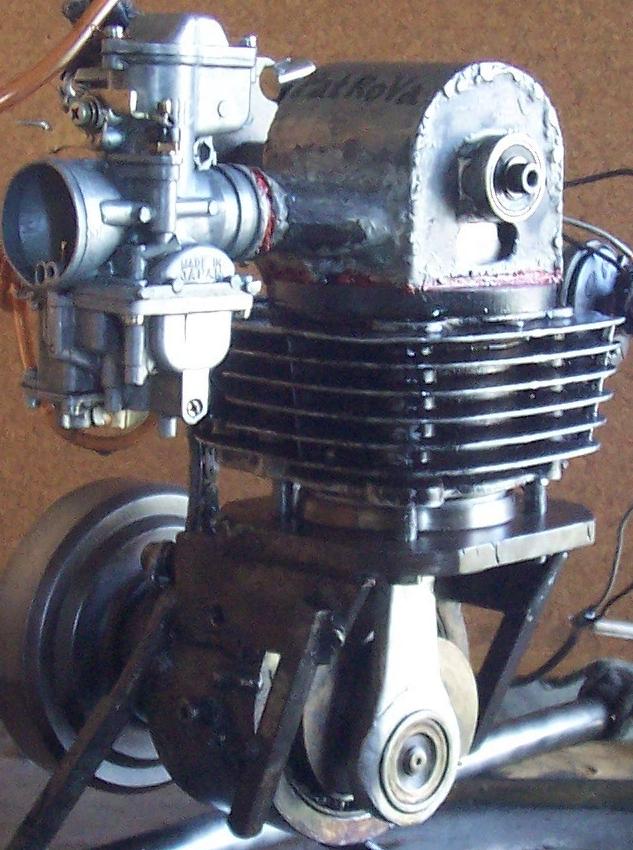

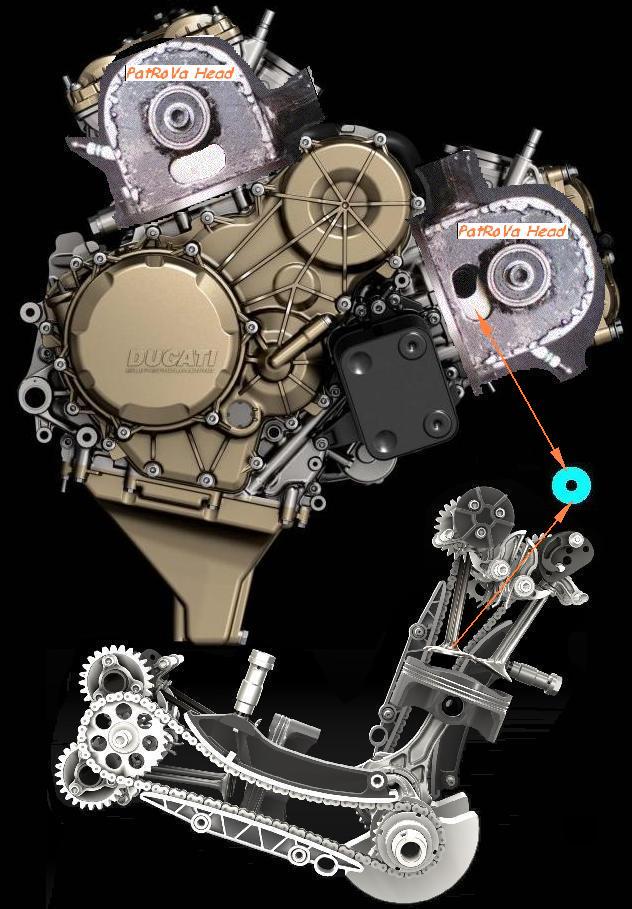

Your PatRoVal engine with rotary seal in intake-and exhaust would have a perfect seal.

I have this model engine, is but no my video. Webra T4-40 wit cross rotary valve. The cross-system is not perfect, has a seal-problem.

The same engine but bigger webra t4-80

I hope you untersood me now.

Thank you Speedman.

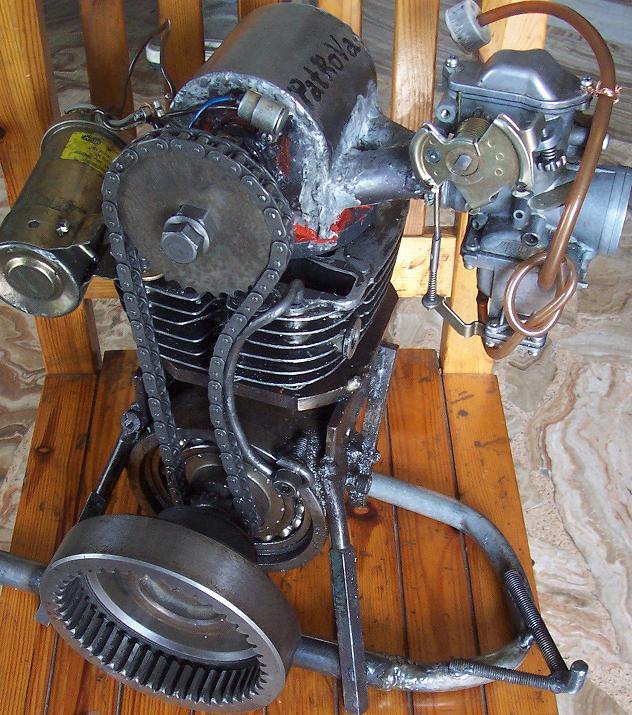

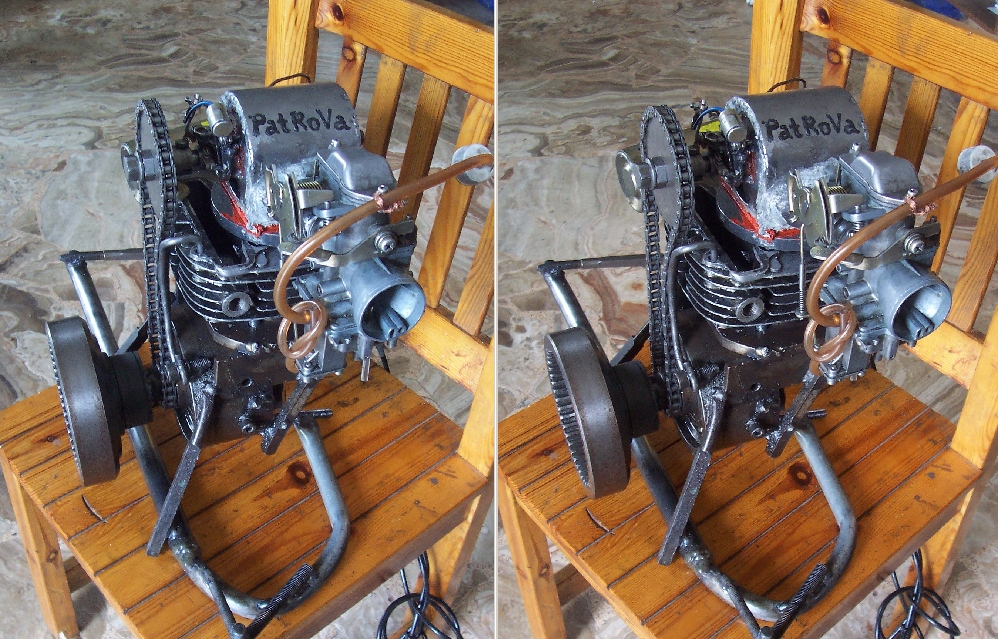

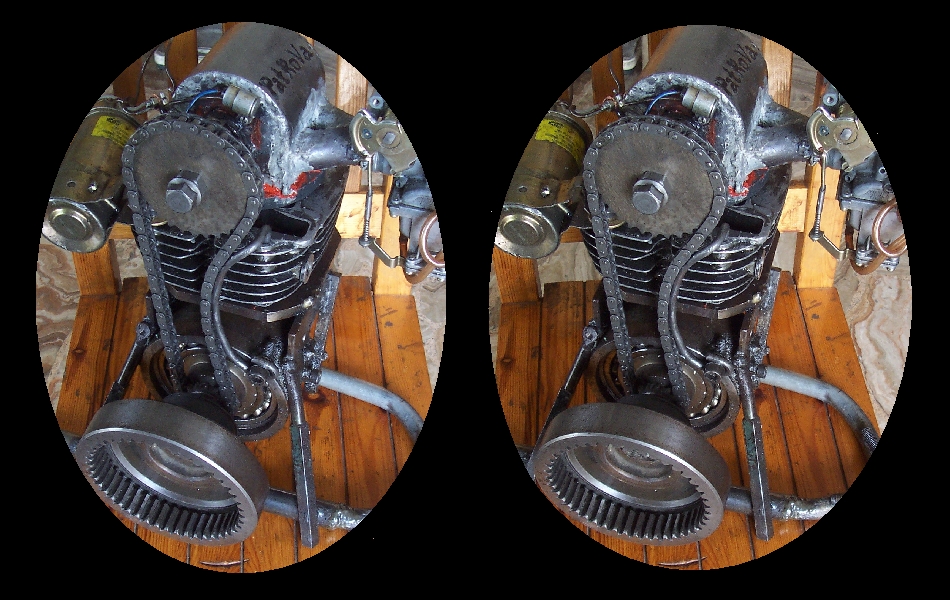

Your prototypes are impressive.

Please correct me if I am wrong in the following:

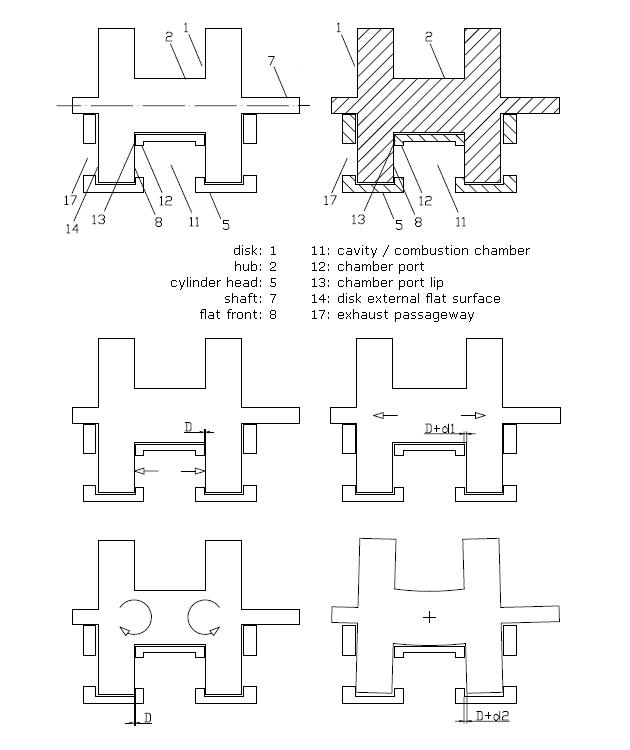

In the DVL system the rotary valve is a thin gear rotating at 1/4 of the crankshaft speed by the gearwheel (R ) at right.

Above the rotary valve there are two intake passageways (E) and two exhaust passageways (A).

The rotary valve has two holes / ports (C ).

Between the rotary valve and the combustion chamber there are two pairs of O-seals (D) for the intake and (D’) (not shown) for the exhaust.

Due to the difference of the linear speed of the rotary valve as it touches each O-seal at its far from the cylinder axis side and at its near to the cylinder axis side, each O-seal rotates about its center. It does not revolve about the cylinder axis. It just rotates into its “groove”.

So, the groove of the O-seal (D) is stationary / fixed. Only the O-seal rotates.

In the case of the PatRoVa the O-seal will be placed in a groove of the cylinder head (as you draw it). The O-seal spins around its axis. The groove of the O-seal is stationary on the cylinder head.

Due to the difference of the linear speed of the disk on the outer and inner sides of the O-seal, the O-seal will rotate.

Question: Where the DVL rotary valve (S) abuts to take the combustion loads?

By comparison, the “combustion forces” acting on the PatRoVa rotary valve cancel each other.

In the DVL system the exhaust ports are only for the exhaust and thereby they are hot (around 800 deg Celsius?), while the intake ports are cold as the intake poppet valves (around 400 deg Celsius?).

By comparison, the chamber ports of the PatRoVa are for both, the intake and the exhaust, so their temperature is significantly lower than the exhaust ports of the DVL system.

In the DVL there are needed four O-seals, in the PatRoVa only two.

With your long experience in the Rotary Valve engines, what is the worst disadvantage you see in the PatRoVa architecture? For instance, in comparison with the state-of-the-art Coates spherical valves.

Thanks

Manolis Pattakos