Hello all.

TDiMeister wrote in another discussion:

“On another note, I would appreciate your input in this thread: https://forums.autos...adan-i4-engine/”.

The Alfadan 4-in-line engine does balance the second order inertia forces of the conventional 4-in-line.

The question is: at what cost?

It multiplies the unbalanced inertia toque on the casing and the shear stress of the crankshaft,

it needs extra “linear” bearings at the bottom of the casing,

its piston assemblies cannot be as stiff as necessary at high revs,

it increases the thrust load and the friction loss,

it is based on unconventional and untested (or unsuccessfully tested: CMC etc) technology.

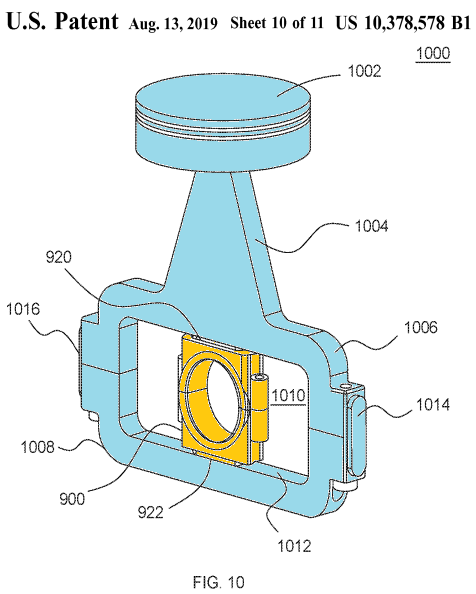

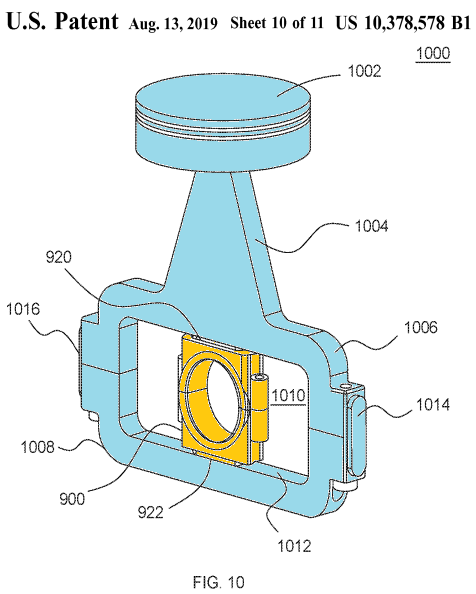

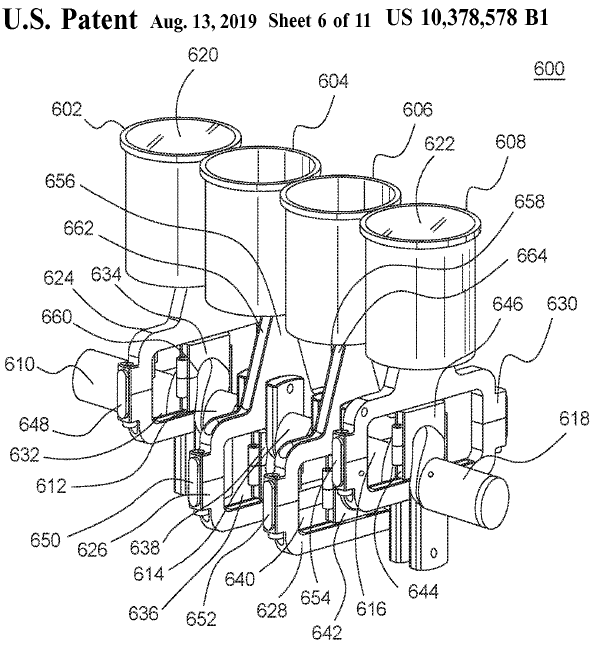

In the Alfadan engine the conventional piston – wrist pin – connecting rod assembly is replaced by the cyan and orange parts:

The cyan part cannot help being a few times heavier than the set of the conventional piston / wrist pin / “upper” connecting rod (“upper” meaning about 1/3 of the weight of the connecting rod; to get an idea for these weights, in the Honda 1600cc V-tec (B15A2) sport engine, the piston weighs 300gr, the wrist pin 100gr and the connecting rod 600gr).

Why the piston of the Alfadan cannot help being so heavy?

Because it needs to be quite inflexible, despite its big opening (the opening inside which the orange part is trapped and slides).

Consider the piston of the Alfadan engine is at the overlap-TDC (no pressure in the cylinder) at high revs.

Who keeps the piston from hitting the cylinder head?

The long horizontal beam (1008 – 1012) which, supported at its middle point on the orange part, is keeping - by its ends - the upper piston structure.

At high revs, at the overlap-TDC (note: the other TDC is the combustion-TDC) a conventional connecting rod is so heavily loaded that it extends dangerously with the piston approaching the cylinder head. In some cases this puts the limit for the rev limiter.

If a connecting rod loaded in tension extends, say, by 0.5mm at top revs, imagine how much the horizontal beam (1008 – 1012) will bend.

And when it bends, the orange part looses contact with the top slider of the big opening and later it lands (or strikes) on it.

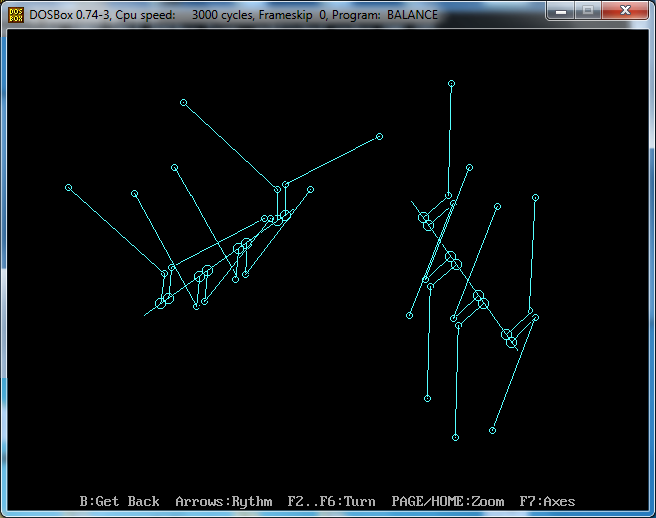

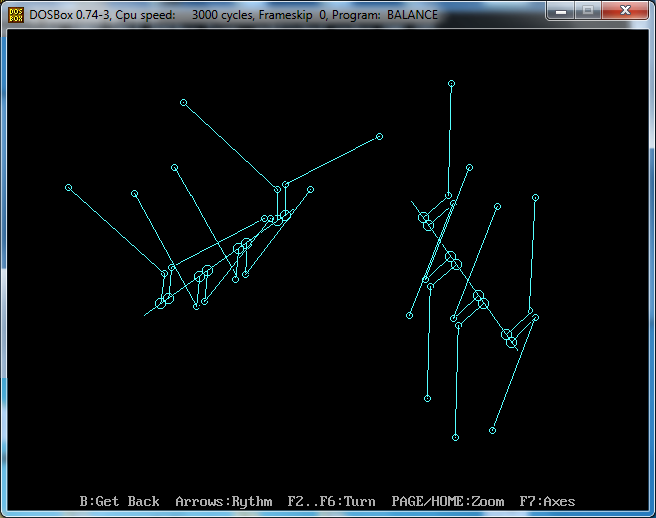

Unbalanced inertia torque:

The necessarily heavy piston assembly of the Alfadan engine increases proportionally the unbalanced inertia torque on the engine casing and on the gearbox.

The thinking is simple: all the four pistons of the Alfadan stop together (the two at TDC, the other two at the BDC, all with zero velocity) and after 90 crankshaft degrees all the four pistons move with their maximum speeds at middle stroke.

Somebody (the crankshaft, the flywheel, the gearbox and the rest vehicle) has to provide kinetic energy to the four heavy pistons when they accelerate, and absorb kinetic energy from the four pistons when they decelerate. All this idle energy (and idle power) reciprocates between the crankshaft and the pistons. The crankshaft with the flywheel tries to keep constant angular velocity while the pistons try to keep their velocities and to accelerate / decelerate the crankshaft with the flywheel, with the crankshaft undergoing heavy to extreme shear loads.

For more, there is the discussion https://forums.autos...que-and-patvra/

Vibration free? And the free inertia torque?

As compared to a similar conventional 4-stroke even-firing 4-in-line engine (say: same bore, same stroke, same rpm) which suffers from a heavy 2nd order unbalanced inertia force and a heavy 2nd order unbalanced inertia torque, the Alfadan engine is free of 2nd order unbalanced inertia force, but suffers from a several times heavier 2nd order unbalanced inertia torque (which may require a pair of balance shafts in order to be cancelled out . . .)

Thrust loads:

The old CMC Scotch-Yoke prototype engine is the boxer version of the Alfadan engine:

As compared to its boxer version, the Alfadan suffers from two times heavier thrust loads between the piston skirt and the cylinder liner. Easy to think why.

So,is there a simple / conventional way (without external balance shafts) to achieve the same?

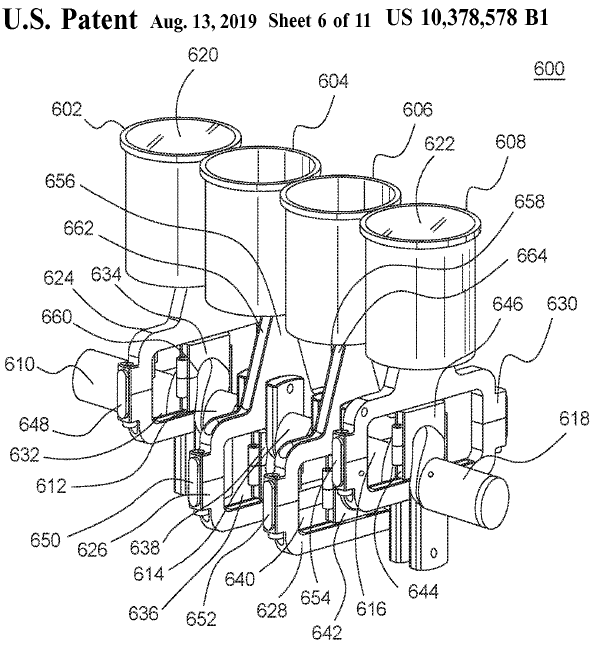

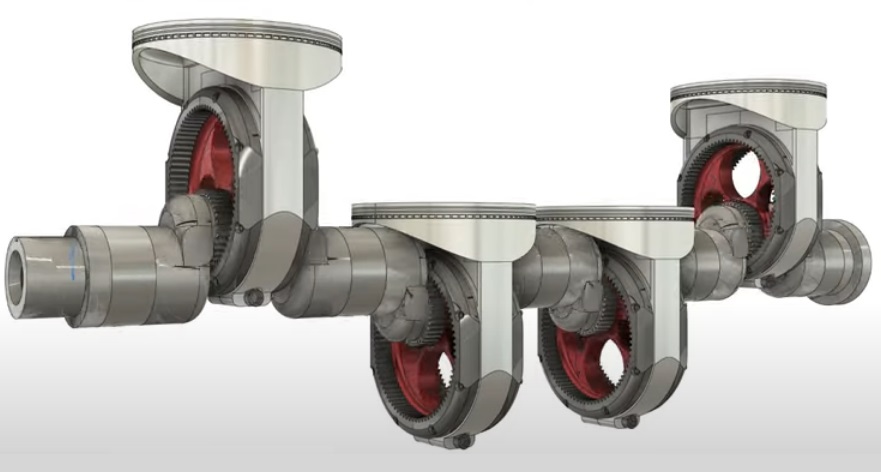

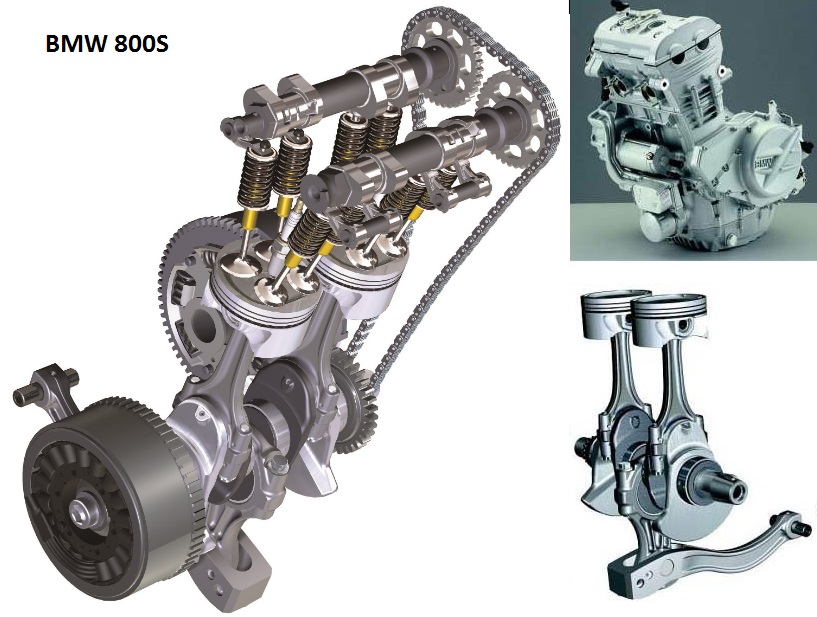

Start with a V8-90 degrees engine with flat crankshaft, say like the engine of the new GM corvette:

Remove the cylinder head from the one bank of cylinders and turn it 90 degrees to form a V180 engine, then turn the engine 45 degrees, say like:

What you get is a four-in-line 4-stroke even-firing full balanced (as regards its inertia forces) engine.

Optionally the lower cylinders can be removed, the lower pistons can be replaced by weights/sliders, and the lower connecting rods can be substantially shorter, and yet the engine be perfectly balanced as regards its 1st and 2nd free inertia forces.

And the solution is completely conventional.

Drawback is the increase of the inertia torque as compared to a similar conventional 4-in-line.

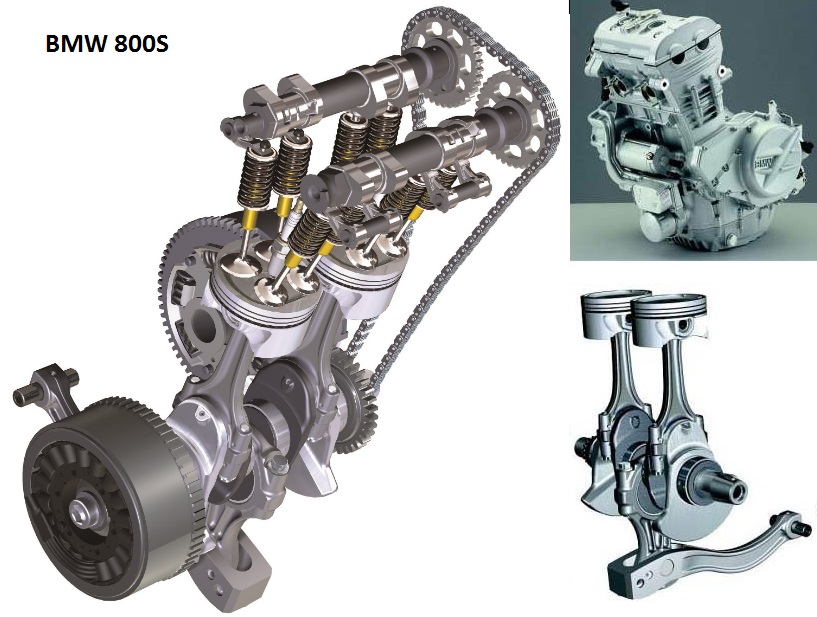

Optionally, the “bottom” cylinders and pistons (or bottom weights and sliders) can be replaced by side connecting-rod-weights like those in the BMW 800S twin:

Conclusion

The Alfadan design solves a problem creating several other problems which are way more difficult to be solved.

If something is confusing please let me know to further expain.

Thanks

Manolis Pattakos

![]()

![]()