https://www.enginela...ry-ofria-story/

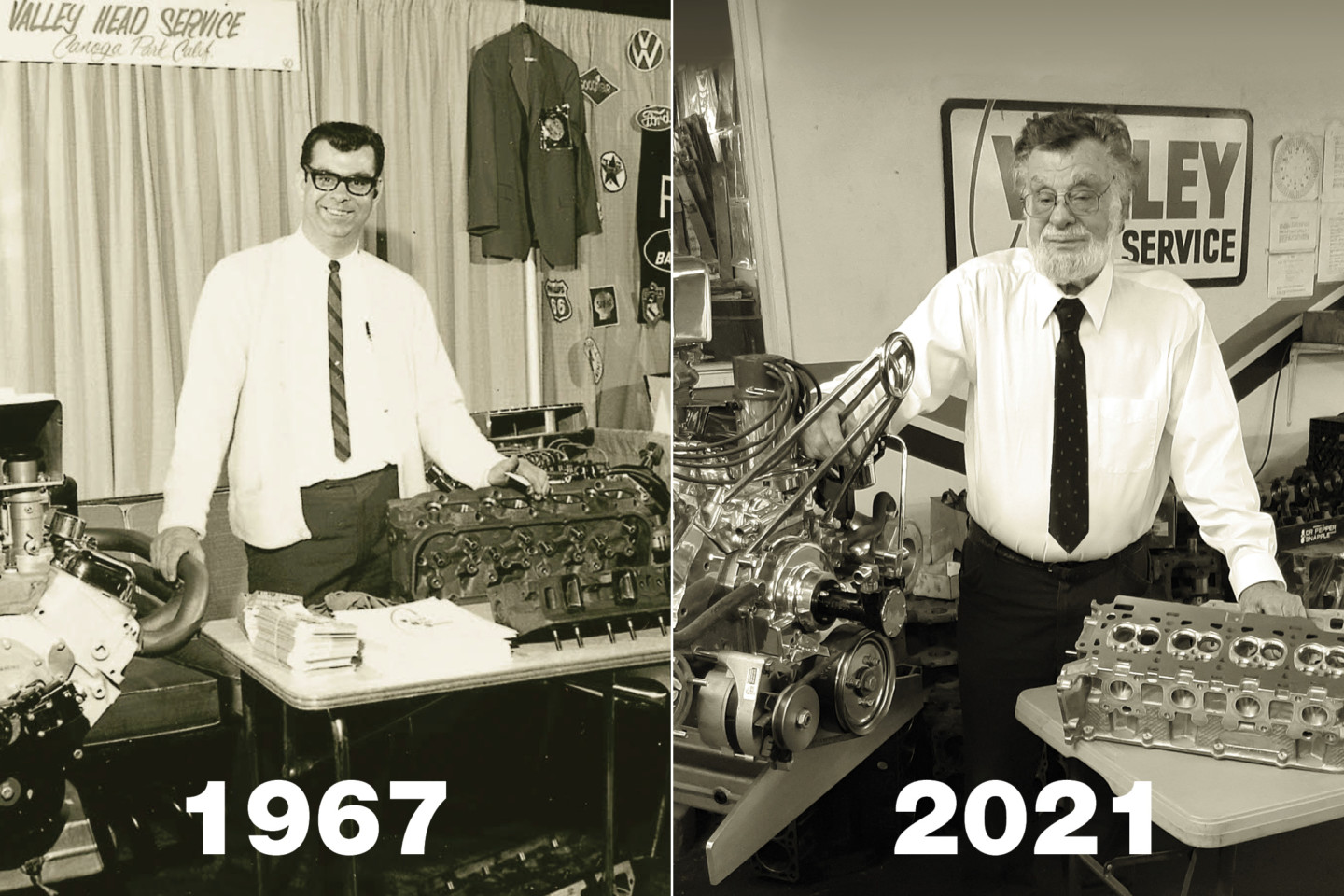

No CNC routines for old iron. Here’s a before/after port modification of a cast iron head. Ofria still practices the art of hand-porting cylinder heads and has done so many in over the decades he could probably do them blindfolded.