Hello Gruntguru

You write:

“So - what is the advantage of the rotating cylinder version? It certainly has several disadvantages.”

QUOTE from the specification of the PatRon patent application:

However the harmonic reciprocating piston engines of the closest prior art (*** it means the Harmonic PatTwo engine, among others ***) have some significant drawbacks, too, like:

The bi-directional and heavy loads on the synchronizing gearing during each combustion (which calls, among others, for reliability issues in the long term),

the "indirect" passing of the power from the piston to the load: the force on the piston crown, due to the high pressure gas in the combustion chamber, passes initially to the crankpin of a secondary crankshaft, then (and loading heavily the synchronizing gearing) it passes, through a set of bearings of higher speed, to the power shaft and to the load,

the difficulty in synchronizing the two halves of the "power shaft",

the heavy inertia loads on the "high speed" bearings by which the "secondary" crankshaft is rotatably mounted on the power shaft: these bearings support the assembly of the secondary crankshaft and of the piston (together with the balance webs on the secondary crankshaft),

the need for additional balance webs on the power shaft, etc.

The present invention addresses, among others, the abovementioned problems:

the combustion does not load the synchronizing gearwheels, the power exits

directly to the load, there is no need for a power shaft comprising two

synchronized halves, etc.”

END OF QUOTE.

The problem with the heavy loads on the teeth of the synchronizing gearwheels is met in the LiquidPiston engine, too, as discussed in post #6: the super-over-square “chamber” of the LiquidPiston receives a huge gas pressure force and, due to the design of the engine, it loads heavily the teeth of the gearwheels.

Take the direct injection 2-stroke Diesel PatRon in the post #16, and a similar non-rotary (say, like the PatTwo) version of it.

120mm bore and, say, 100bar peak pressure during the combustion means a peak pressure force of 11tons (110,000N) on the crankpin of the PatRon and on the crankpin of the secondary crank of the PatTwo.

Supposing a high momentum of inertia of the load (which is driven by the crankshaft), the teeth of the two gearwheels of the PatRon remain actually unloaded while the teeth of the two gearwheels (ring gear / spur gear) of the PatTwo are loaded by several tons of force. Besides the frictional loss, it is also the longevity of the engine (if the teeth of the gearwheels start wearing, the resulting backlash when the piston passes from a TDC makes the load impact and accelerates the further wear).

In the Harmonic PatTwo there are two crankshafts: the secondary and the main crankshaft (or power shaft). The secondary crankshaft spins and orbits, with its bearings revving at double speed. The orbiting motion (and the necessarily heavy assembly of the secondary crankshaft with its balance webs and with the piston) creates strong centrifugal forces. The engine needs a strong secondary crankshaft to receive the heavy loads, but it also needs a lightweight (and with small diameter journals) secondary crankshaft in order to reduce the inertia loads on the double-speed bearings and to lower the relative frictional loss.

Worse even: the single sided support of the secondary crankshaft of the PatTwo.

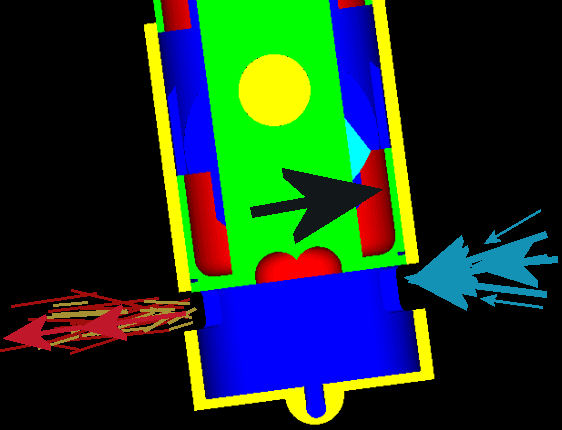

If, in order to support at both sides the secondary crankshaft, another power shaft at the other side of the cylinder is mounted, it is required a set of four gearwheels (like the 2B, 3B, 7A, 7B in the following drawing) to synchronize the two halves of the power shaft and keep them perfectly aligned (otherwise the secondary crankshaft falls apart).

More gearwheels and shafts means more friction, higher cost, more weight, more wear etc.

Or, see how straightly / directly / immediately the gas pressure force on the piston passes to the load of the PatRon without loading anything (neither the cylinder liner, as happens in the conventional engines, nor the synchronizing gear wheels, as happens in the PatTwo and in the LiquidPiston).

In comparison, in the PatTwo the gas pressure force passes initially to the secondary crankshaft and to the gearwheels, and then, through the double-speed bearings, it passes to the power shaft and to the loads. More passages of the energy means more frictional loss.

For several applications the spinning cylinder is a problem (or seems like a problem).

However with the spinning – and rid of thrust loads – cylinder of the PatRon, the cylinder can be made thinner and more lightweight, keeping its cylinder more cylindrical than the cylinders of the conventional engines with the thrust loads.

With the over-square design (120mm bore x 60mm stroke; the bore to stroke ratio is just a bit higher than in the Ducati Panigale 1299) the maximum dimension of the rotating cylinder is 280mm (a typical flywheels is of bigger diameter).

The spinning cylinder gives the opportunity for a built-in aircooling and for automatic scavenging without a scavenge pump.

The characteristics of the 2-stroke PatRon di Diesel of post #16 talk:

for several times smaller weight than an equal power conventional 4-stroke Diesel,

for higher fuel efficiency (better shape of the combustion chamber, more time for the preparation and combustion of the diesel fuel, way lower frictional losses (it is a 2-stroke rid of thrust loads on its cylinder liners, which means a specific lube consumption similar to that of the four strokes and similarly clean exhaust), low pumping loss, etc)

for perfect balancing,

for compact design,

for smaller cost, etc.

It seems as an ideal power unit for small airplanes, helicopters, flyers etc, even for power generator sets (imagine the PatRon in a cage fed with filtered air for both, aircooling and breathing, and driving an electric generator directly secured on its crankshaft).

Thoughts?

Objections?

Thanks

Manolis Pattakos