Story by Lucas Bell

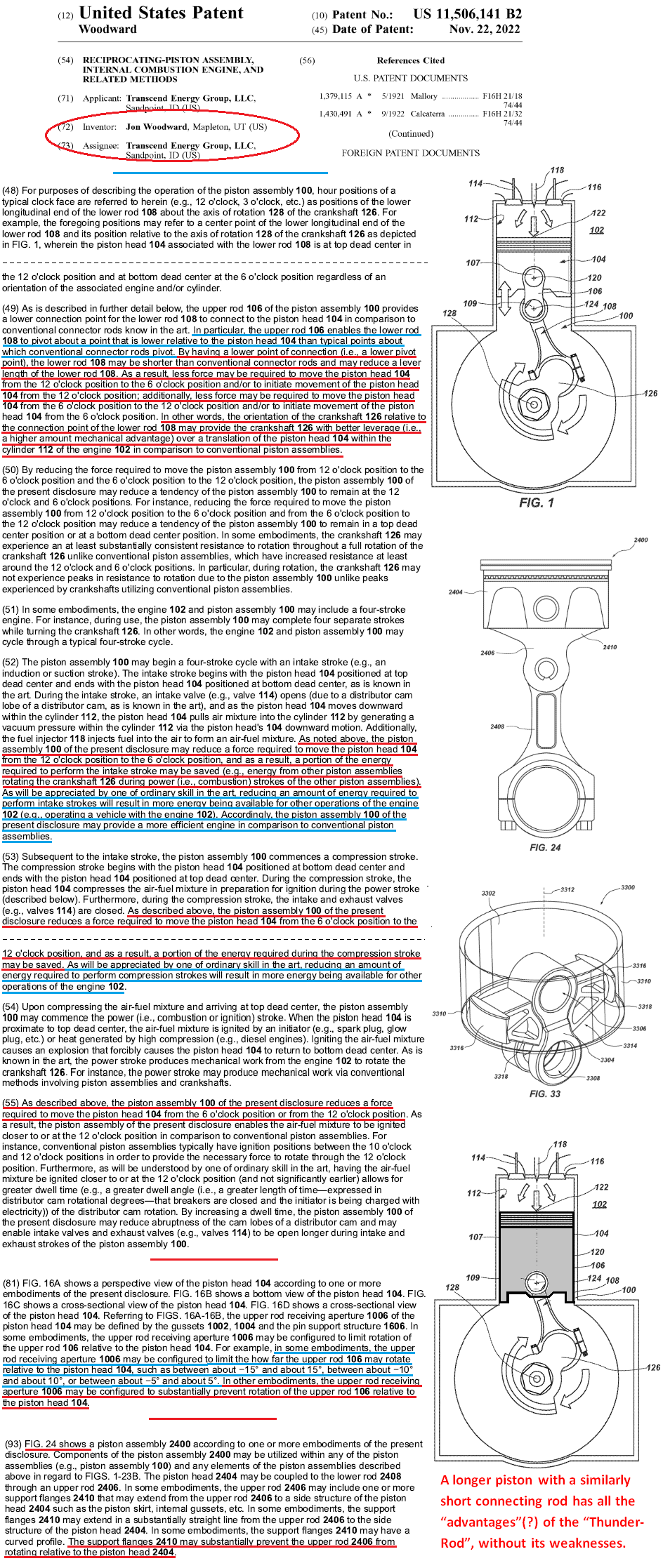

The annual SEMA Show in Las Vegas always brings fans of the automotive aftermarket loads of new hardware to check out. Transcend Energy Group made waves this week by unveiling the industry’s first two-piece connecting rod known as the Thunder Rod, which aims to improve both efficiency and performance of the internal combustion engine. R&T visited with president and chief product officer Jon Woodard on the SEMA Show floor to get a better understanding of the gains this one simple part can provide. We also spoke to industry experts to try and get their take on the Thunder Rod's viability.

This is an exciting piece of tech that has drawn a lot of eyeballs both at SEMA and in the run up to the show, offering theoretical gains through out-of-the-box thinking. It was very hard, however, to find an expert who would so much as go on the record talking about whether or not any of these claims sounded plausible in the real world. But before we dive into all that, let's talk about the basics of what's being presented.

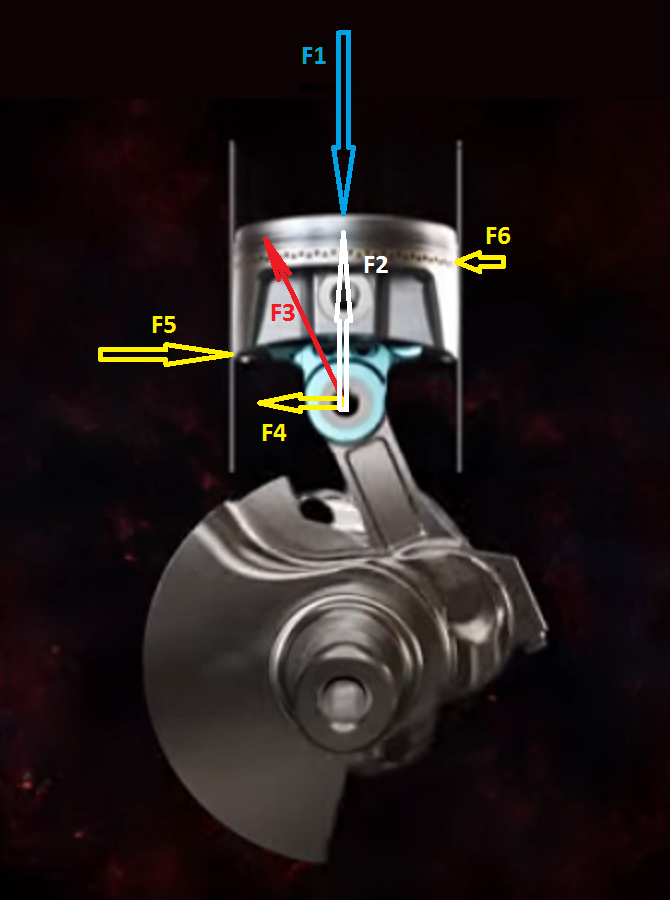

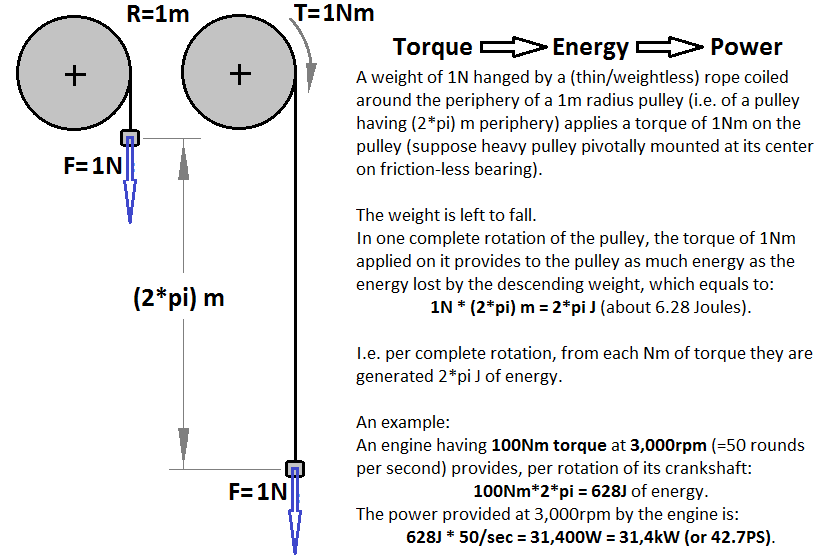

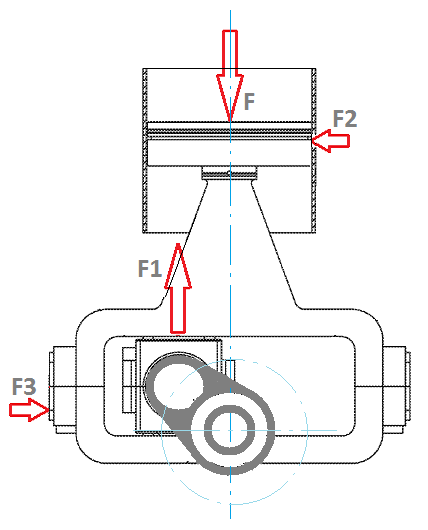

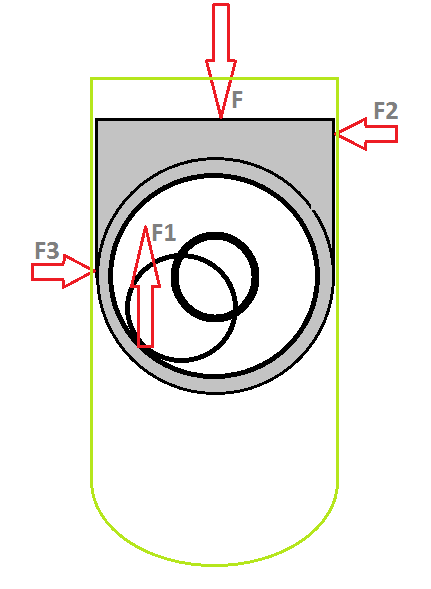

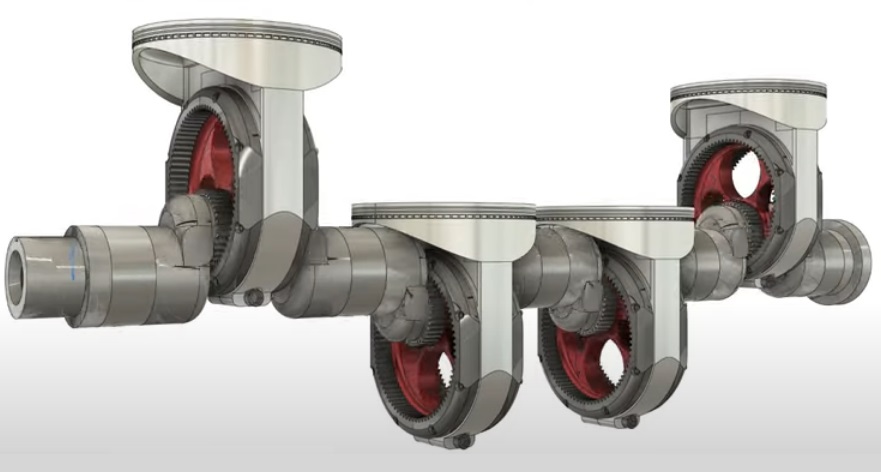

A connecting rod is not a complicated bit of engine hardware. In the basic most sense, a con-rod attaches a piston to an engine’s crankshaft, transforming reciprocating energy from the piston’s travel into the rotational energy responsible for spinning the crank. While material science and manufacturing processes have improved traditional con-rod designs over the last century or so, Transcend is the first company to roll out a two-piece unit. Instead of a traditional setup where the piston itself is a pivot point, this design moves that pivot location down onto the arm of the connecting rod. This setup creates a much more linear motion of the piston, which in turn improves the overall volumetric efficiency of the motor. Part of that comes down to the fact that the Thunder Rod uses saddles mounted inside of the piston itself to reduce piston rock and cut down on the need for thick piston skirts often found on performance pistons.

“One of the advantages that this provides is that we use the inside of the piston,” Woodward told R&T. “With the setup you don’t have to use a thick skirt. The magic is the rotation on the saddles. That allows the piston to stay neutral on the non-load side and engage only on the other side. It doesn’t try and rip itself out of there. The harder that it pushes, the more it tries to keep things flat. You can just imagine pushing something between your hand and a wall. I think in the future we’ll find that you don’t have to use skirts at all, and instead use a frictionless material like Teflon or something to make shoes that reduce that friction further.”

Development work on the Thunder Rod has been limited to 5.3-liter and 6.2-liter LS engines thus far, but there are good reasons for that. Woodward noted that the team wanted to utilize a computerized engine for data collection purposes, and the affordability of the platform overall gave it an edge over something like an overhead cam motor from Ford. It also doesn’t hurt that the aftermarket is in love with LS engines, with unrivaled part availability and research.

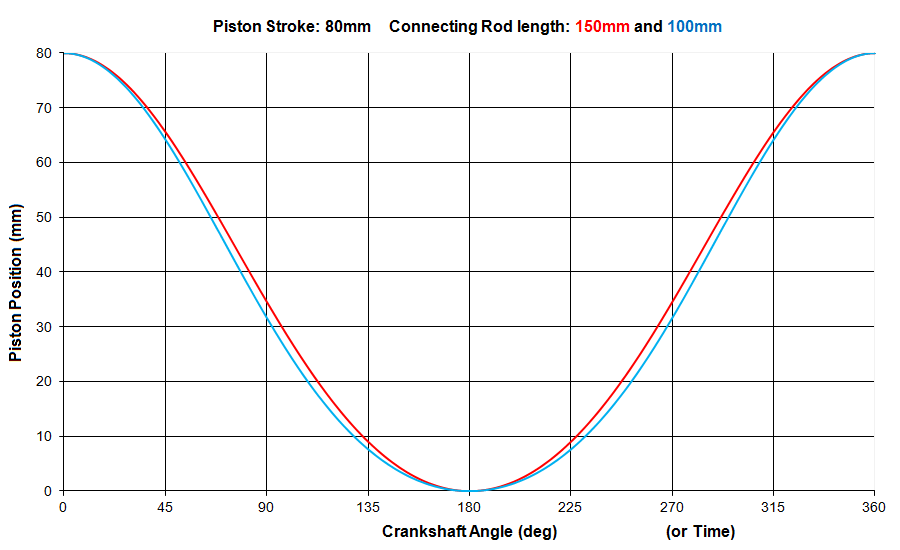

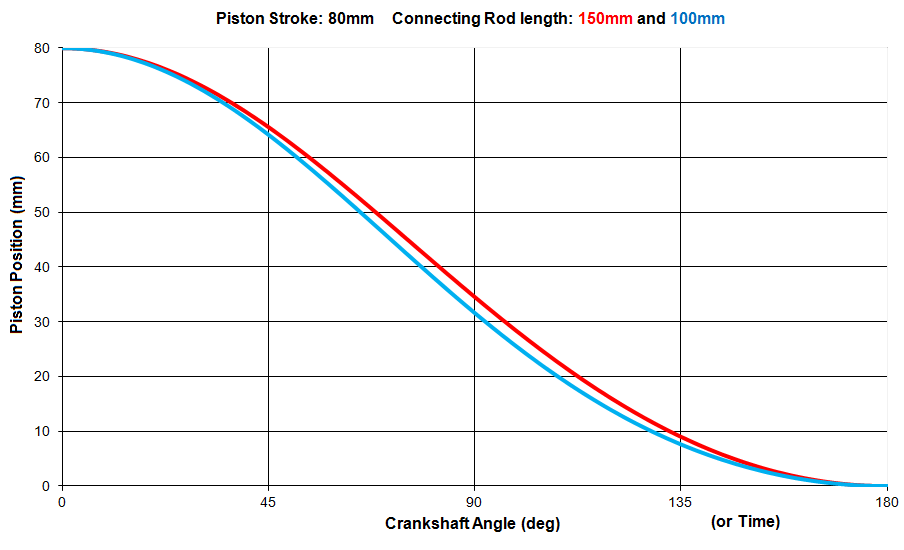

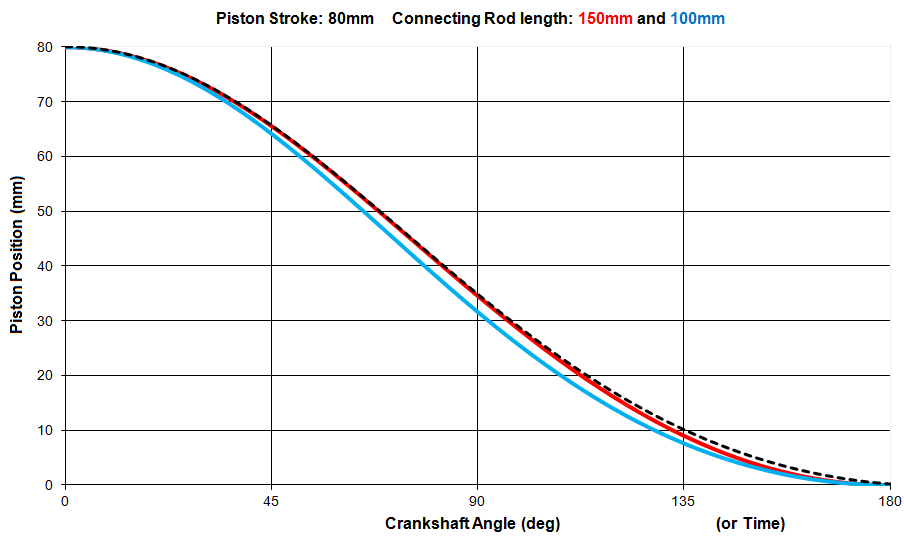

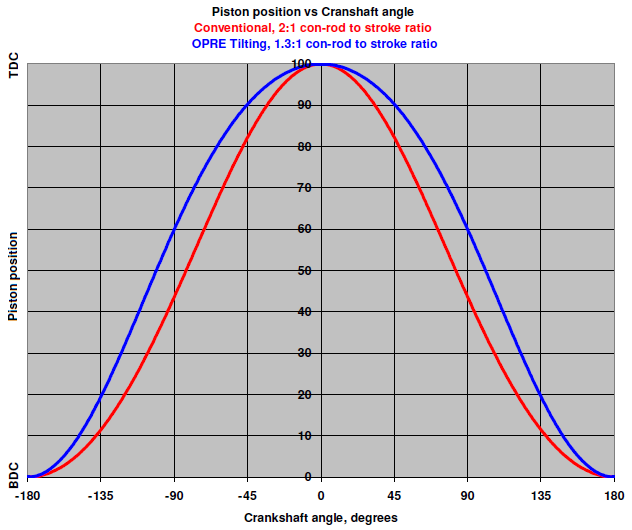

By moving that pivot point down and adding hardware inside of the piston itself, Transcend’s pistons are actually a bit heavier than a stock LS piston. The added weight doesn’t limit overall piston speed in any way, but it does change how quickly the piston moves through different parts of its stroke. The Thunder Rod increases the speed of the pistons by 30 percent off of top dead center, while providing an equal amount of dwell on the way down.

“It’s faster where it counts and it's slowed where it doesn’t really matter,” said Woodward. “When you’re drawing the air in, you want it to suck it in fast to get that intake velocity up. Once you shut the valves and start to pack the air, the slower you pack it the more air escapes through the rings. The faster you can pack that air, the more punch it has. Think about a hand pump. You can pump it slowly, but it's much more effective if you have a faster motion.”

For the time being, Transcend Energy Group is only working on testing the Thunder Rod in a stock-for-stock comparison. While they’ve already found great headroom inside the LS with just this single part, the rest of the engine isn’t really designed to function in this way. Take the pistons themselves for example, which are currently wearing a profile that doesn’t maximize the potential of the Thunder Rod. Woodward is currently working to find a more appropriate piston in the existing pool of aftermarket components. Other items like the heads and the camshaft haven’t been tuned for the system either, and could help bring even more power potential to the equation. The team is actively speaking with OEMs for their opinions on how to better improve the system collectively.

“All of the innovation that happens is the result of people taking things and thinking outside of the box,” Woodward said. “If you don’t do that and you get tunnel vision, and you think inside the norm all of the time It’s hard to create something new. People have done so much of the same. The industry is stagnated a bit with engines, which is why they’ve created better oils to keep trying to get friction out of the engines. Internal combustion engines are very inefficient, maybe 25 or 30 percent efficient. That might be closer to 60 percent in something like an F1 engine. There’s still a long way to go with the combustion engine, but we have to start thinking outside of the box.”

It is easy for a company like Transcend Energy Group to make big claims when it comes to a new product, particularly one for which they've been awarded domestic and international patents for. That said, R&T reached out to a number of engine builders and automotive experts to try and validate the performance gains being touted here. The consensus was that while the Thunder Rod is an intersting bit of engineering work, without actual data being published by the company there is little that can be said about the viability of the product.

"They claim changes in dynamic compression ratio, that would need to be measured, or I mean you could certainly calculate the piston position versus time and see how that changes," Southwest Research Institute's Kevin Hoag told R&T. "It doesn’t sound like a very big effect. If that intermediate piece is fixed in there, I struggle to see how they are eliminating piston rocking or secondary motion of the piston. I would challenge them to actually provide the calculations and demonstrate that. I think that’s generally where this design is at. There are some things that are being changed, what real effect that they have needs measurement and demonstration.

Until Transcend Energy Group is done with development of the Thunder Rod and more folks within the aftermarket get a chance to work with the new hardware, there will still be questions about the part's effectiveness. Two-piece con rods are new to gasoline-powered engines, but marine diesels and old steam engines have utilized a crosshead con rod layout for decades. Whether that speaks to the performance capabilties of the Thunder Rod will have to be seen. That said, it's exciting to see companies still invested in improving the internal combustion engine this late in its lifecycle.